Two-phase gas-liquid flow capacitive sensor

A capacitive sensor, gas-liquid two-phase flow technology, applied in the direction of material capacitance, volume/mass flow generated by electromagnetic effect, etc., can solve the problems of large measurement error, low efficiency, low cost, etc., achieve low cost, long life, The effect of precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

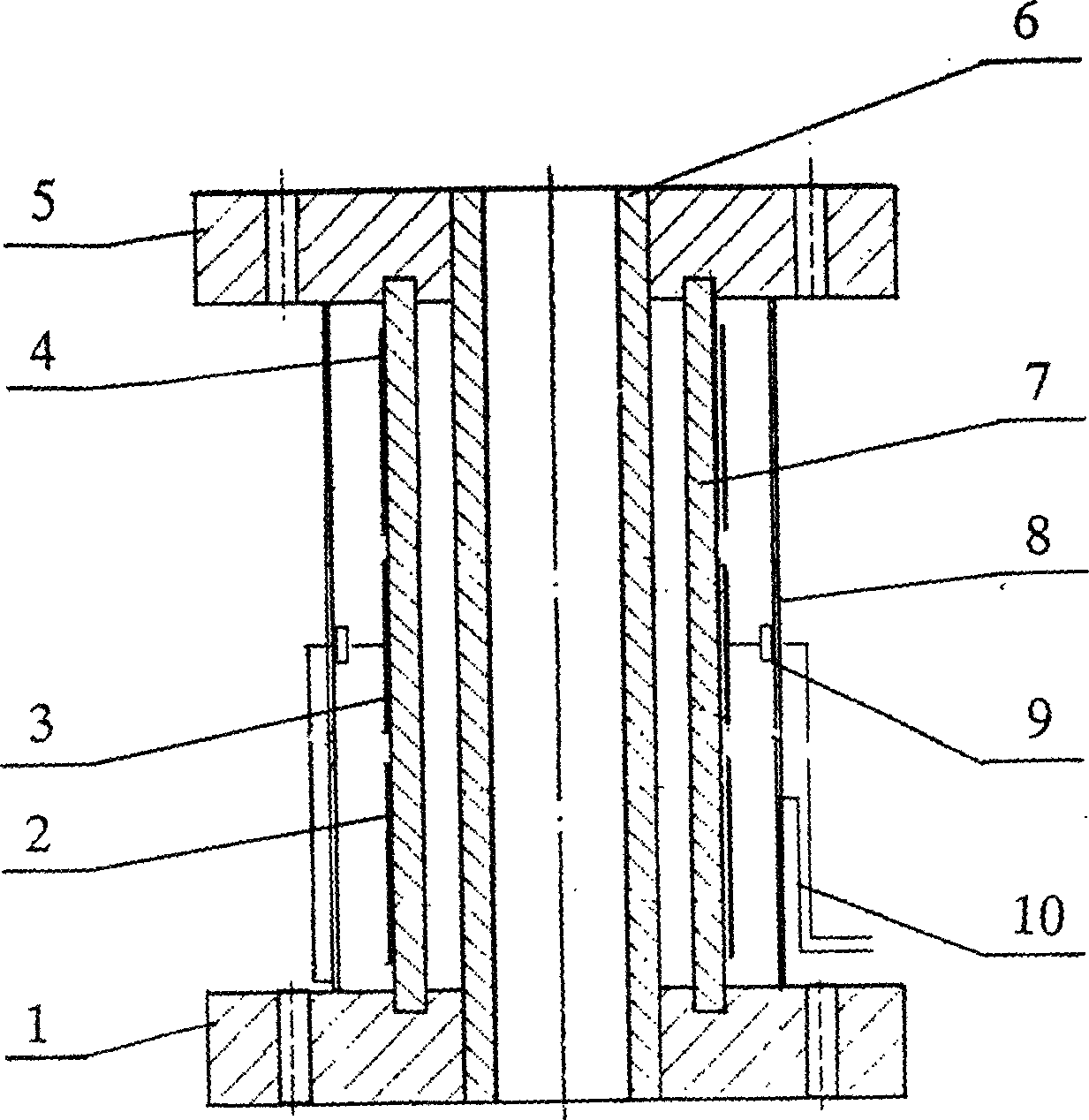

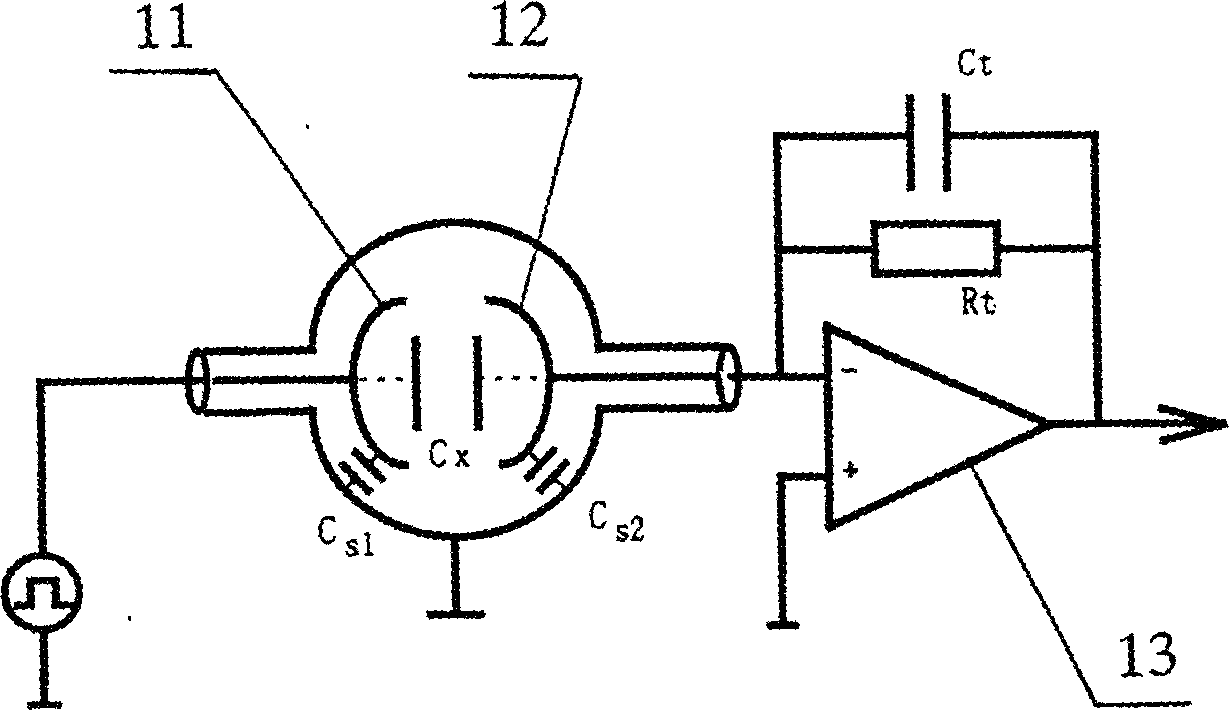

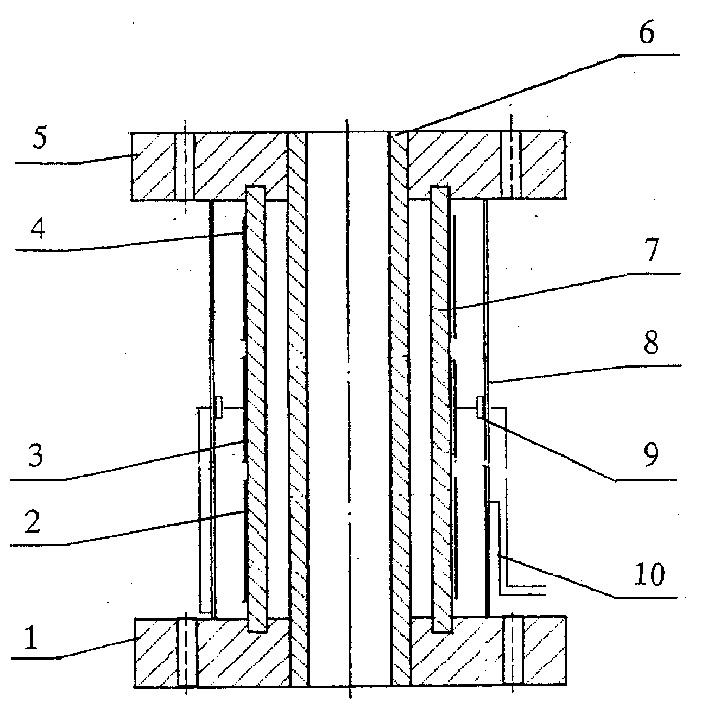

[0009] Such as figure 1 and figure 2 As shown, the technical scheme and structural principles of the present invention are further described in conjunction with the embodiments. A gas-liquid two-phase flow capacitive sensor, the two ends of the connecting pipe 6 of the sensor are respectively fixed with a flange 1 and a flange 5, and the pole plate tube 7 and the galvanized plate shield 8 are respectively fixed on the flange 1 Between the plate tube 7 and the flange 5, the plate tube 7 is arranged in the middle, and the shielding cover 8 is arranged in the outermost layer. The capacitor plate 3 is composed of a power supply plate 11 and a detection plate 12, which are respectively arranged on the outer circle in the middle of the plate tube 7, and the two sides of the outer circle are respectively provided with a protective plate 2 and a protective plate 4 with the same structure. Copper foil for plate and protective plate material. The capacitor plate 3 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com