Exhaust silencer

A technology of exhaust muffler and muffler, which is applied in the direction of exhaust device, muffler device, machine/engine, etc., and can solve the problems of complex manufacture of resonance tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

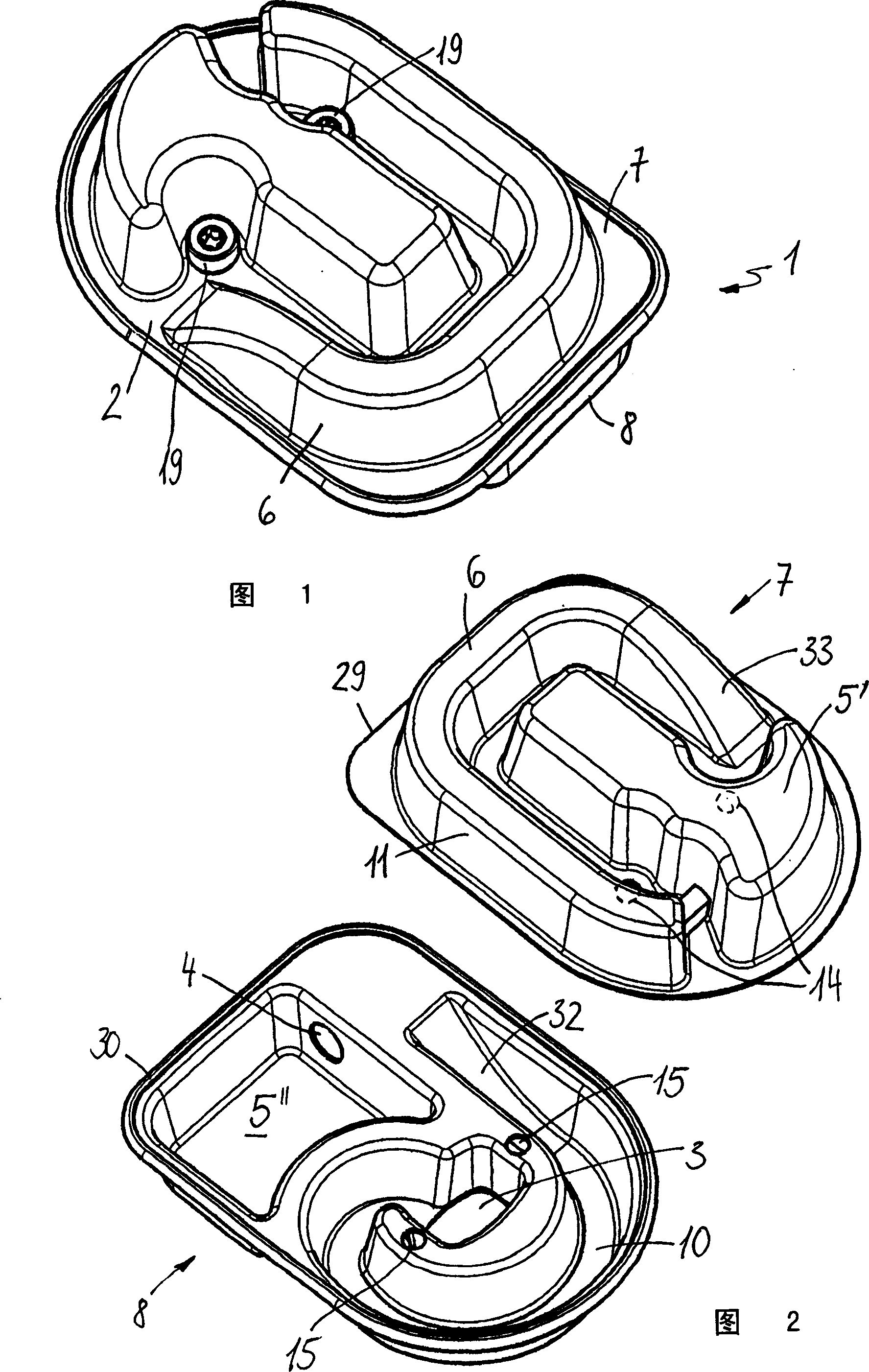

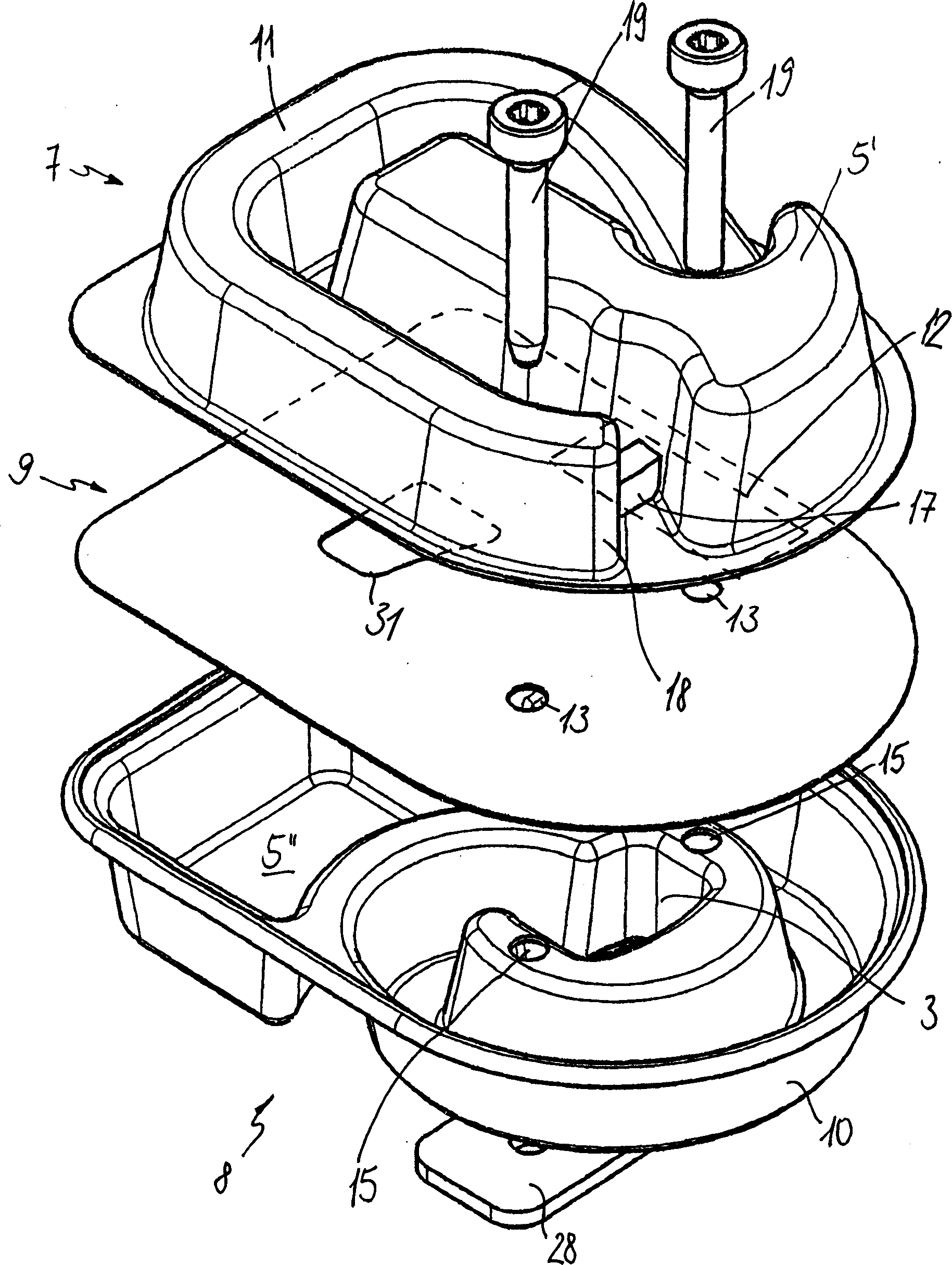

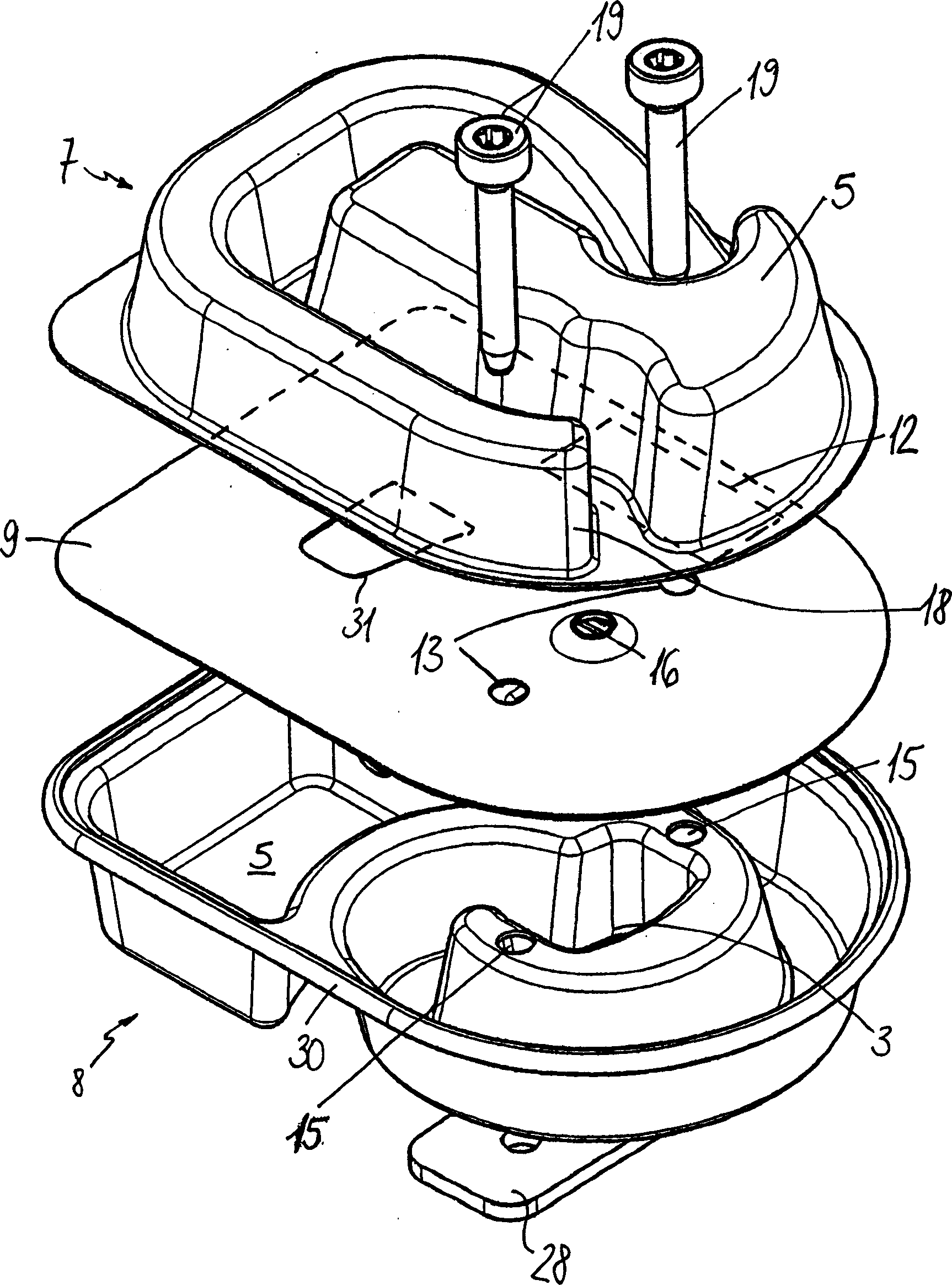

[0018] The exhaust muffler 1 shown in perspective in FIG. 1 has a muffler housing 2 which is formed from an upper half-housing 7 and a lower half-housing 8 . The two half-shells are made of deep-drawn sheet steel, which are connected to each other at the edges shown in FIG. 2 . The edge 30 of the lower half-shell 8 surrounds the edge 29 of the upper half-shell 7 and is crimped around it. In order to fix the exhaust muffler 1 on an internal combustion engine, the upper half shell 7 has two fastening holes 14 and the lower half shell 8 also has two fastening holes 15 . The fastening holes 14 and 15 lie one above the other when the half shells 7 and 8 are fastened. The exhaust muffler 1 can then be fastened to an internal combustion engine with fastening screws 19 protruding through the fastening holes 14 and 15 .

[0019] In the lower housing half 8 pointing toward the internal combustion engine, an inlet opening 3 is provided, the cross section of which reasonably corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com