Semiconductor device and producing method thereof

A manufacturing method and semiconductor technology, which is applied in the field of semiconductor devices and semiconductor device manufacturing, can solve problems such as the bad influence of gate insulating films, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

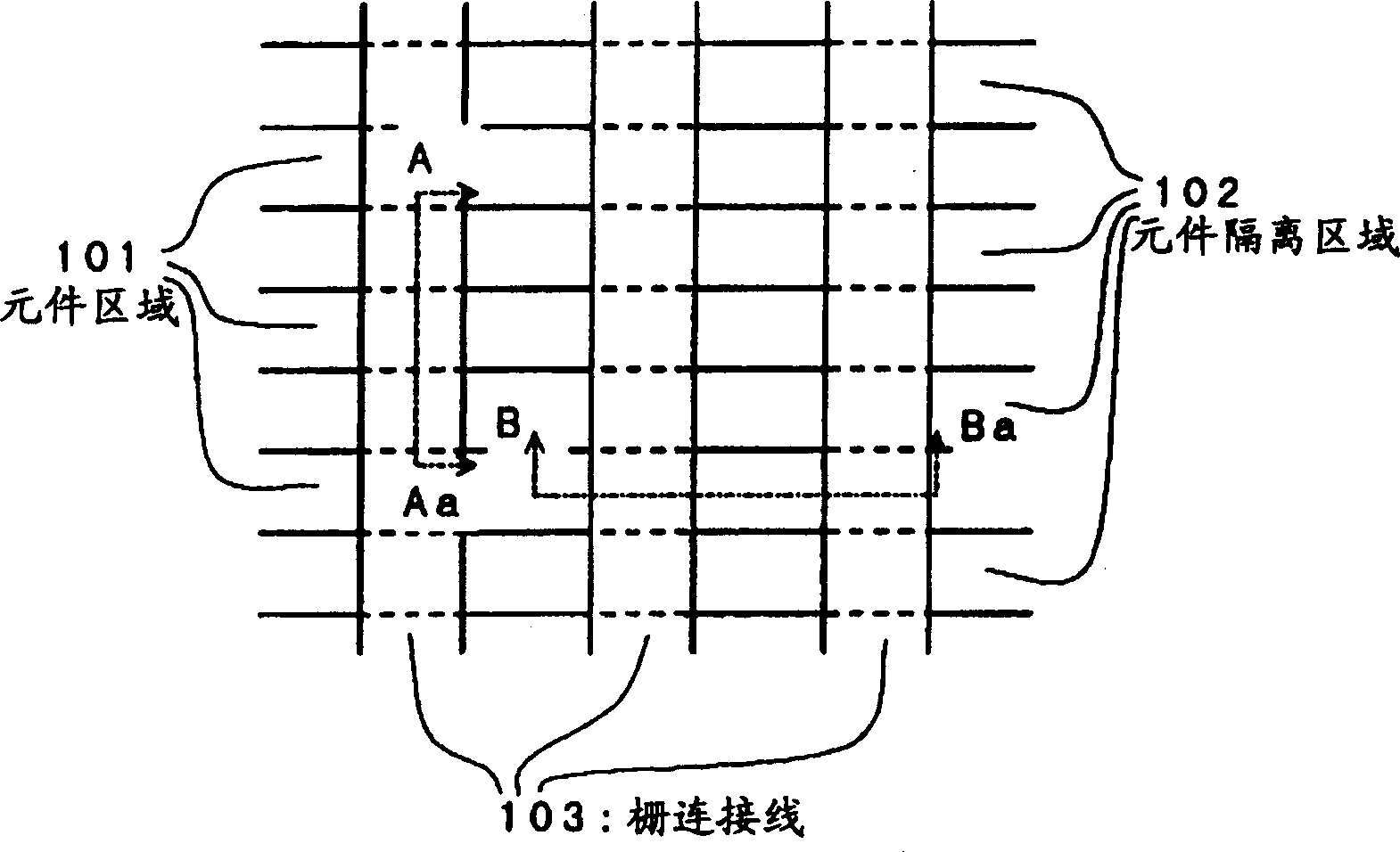

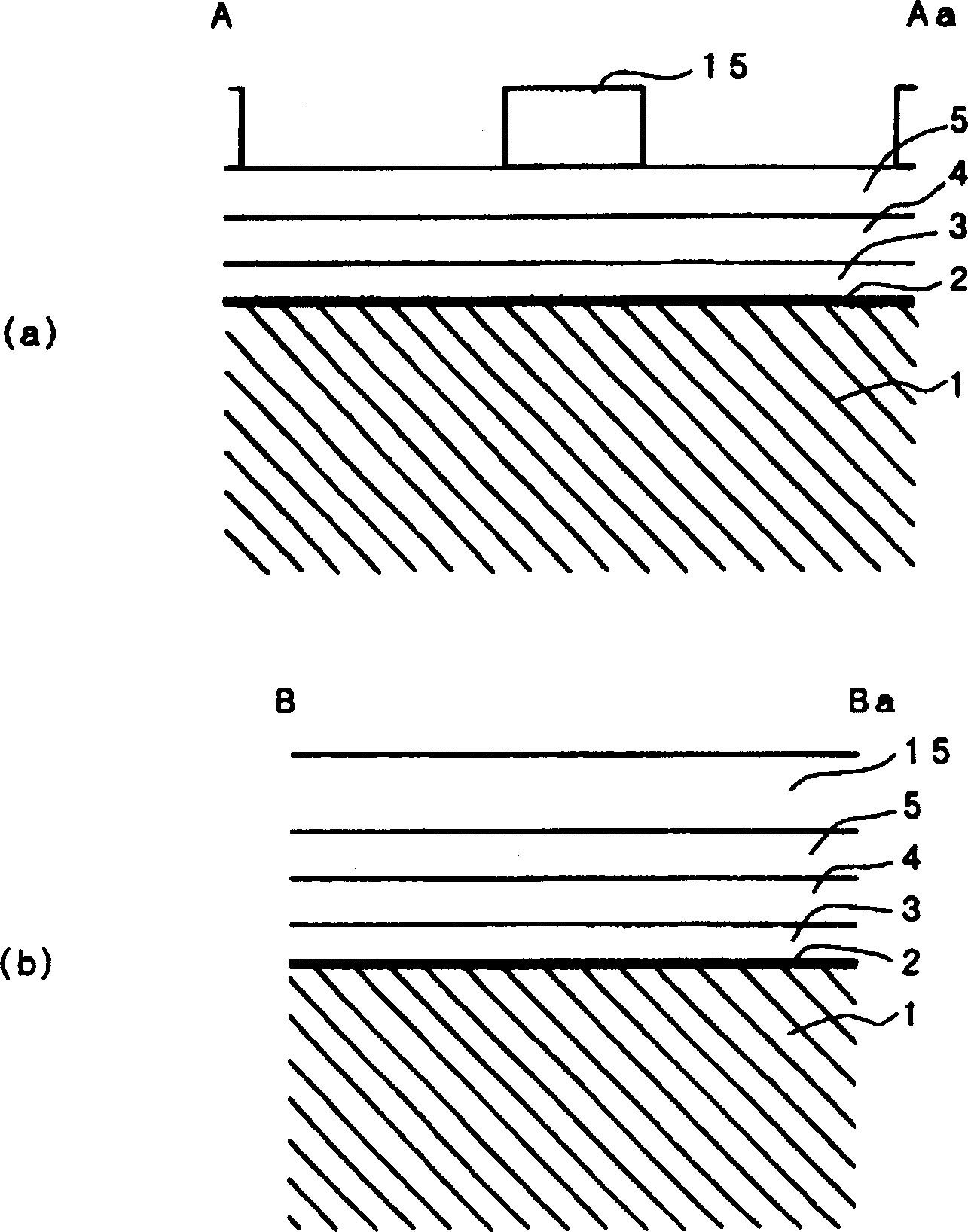

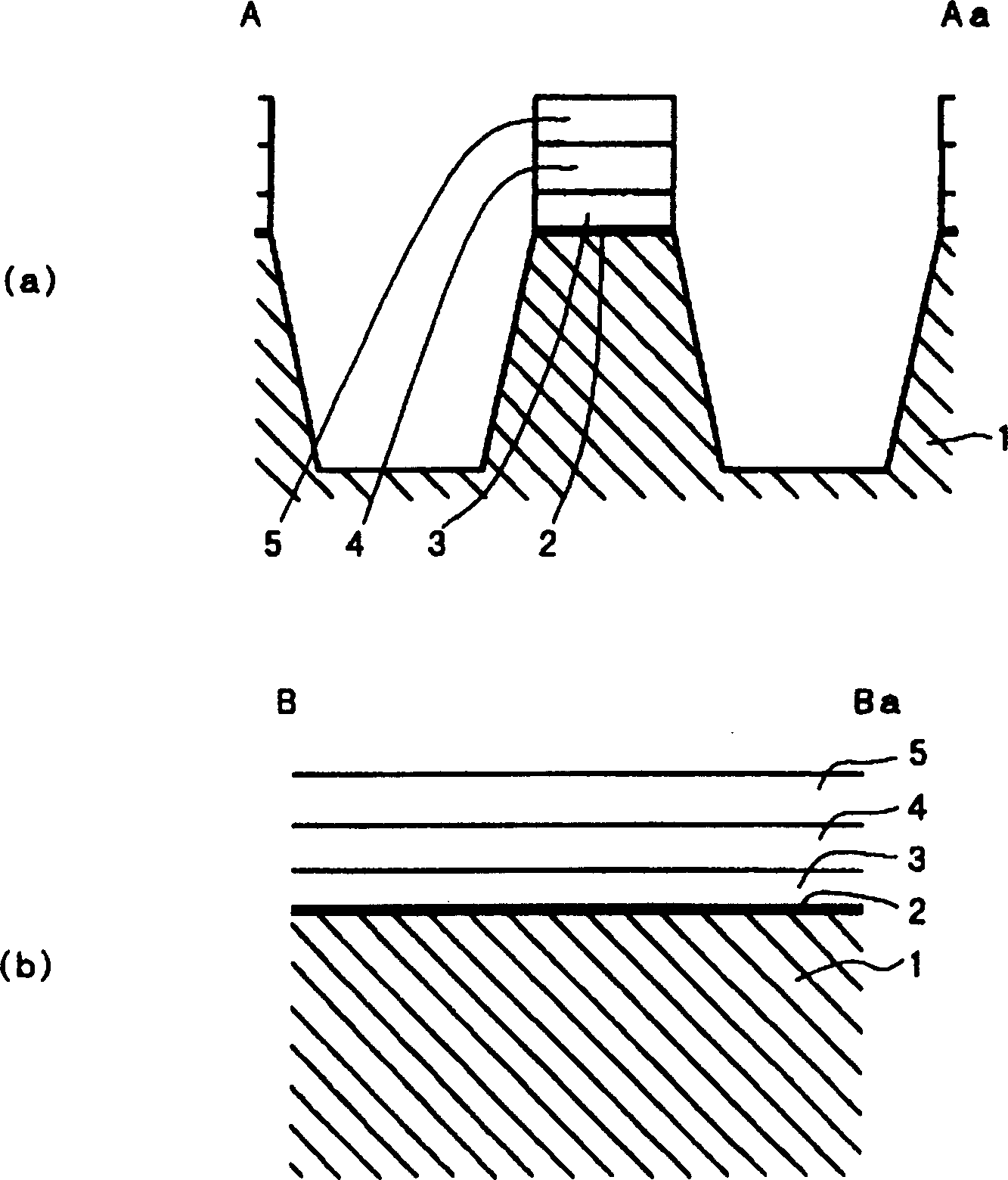

[0034] Based on the above, a nonvolatile semiconductor memory as an example of an embodiment of the present invention will be described below with reference to the drawings. figure 1The plan view of FIG. 2 schematically shows the configuration of a nonvolatile semiconductor memory according to an embodiment of the present invention. As shown in the figure, in this nonvolatile semiconductor memory, cells (MOS transistors having floating gate electrodes) serving as memory elements are arranged in an array.

[0035] That is, element regions 101 and element isolation regions 102 that isolate these element regions 101 are alternately arranged in stripes, and one element region 101 has a plurality of cells in the left-right direction in the figure. In the direction perpendicular to the direction in which the element region 101 extends, the gate connection lines 103 connecting the control gate electrodes are also formed in stripes.

[0036] A floating gate electrode (not shown) is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com