Method of making paper pipe, paper board using paper powder

A paper powder and cardboard technology, applied in the direction of solid waste removal, etc., can solve the problems of not being able to fully utilize the production cost of shredded paper, reduce space, etc., and achieve the effect of good product strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

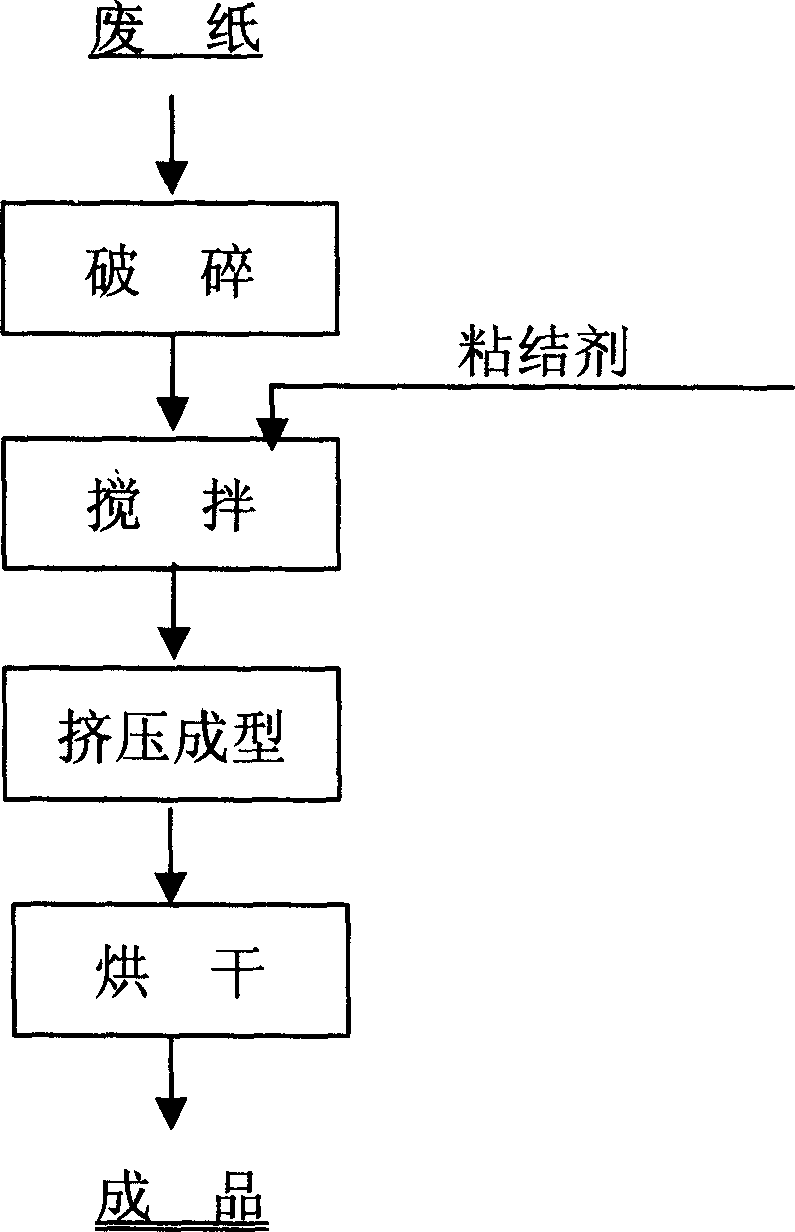

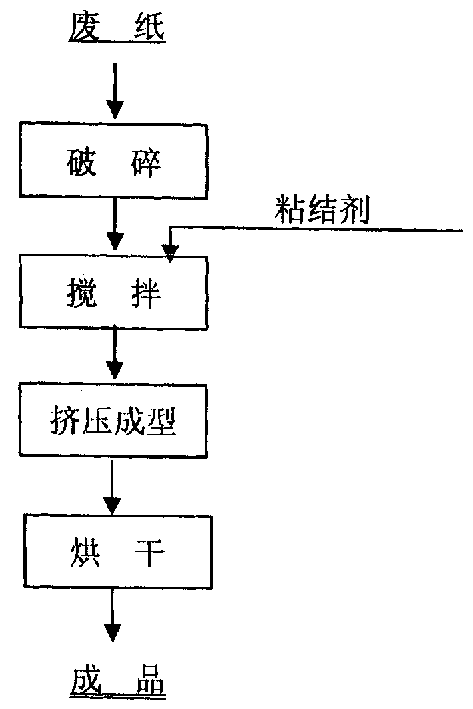

Method used

Image

Examples

example 1

[0014] First, put any size of paper (corner waste) or waste paper into a shredder and crush it into shredded paper powder with a particle size of <1mm, then stir the paper powder in a mixer and add binder latex glue (also known as paper tube glue) , Ningbo Zhenhai Yongcure Factory), its weight ratio is paper powder: latex glue = 1: 0.5, then the paper powder is extruded in an extruder, and finally dried in a drying oven at a temperature of 50 ℃.

example 2

[0016] The particle size of the paper powder is <0.5mm, the weight ratio of the paper powder and the latex glue is paper powder: latex glue=1:0.4, the drying temperature is 45° C., and the rest are the same as in Example 1.

example 3

[0018] The particle size of the paper powder is <0.1mm, the weight ratio of the paper powder and the latex glue is paper powder: latex glue=1:0.3, the drying temperature is 40° C., and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com