Hollow plate

A hollow and planar technology, applied to hollow objects, building components, household components, etc., can solve the problems of increased thickness of hollow boards, increased costs, and increased number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

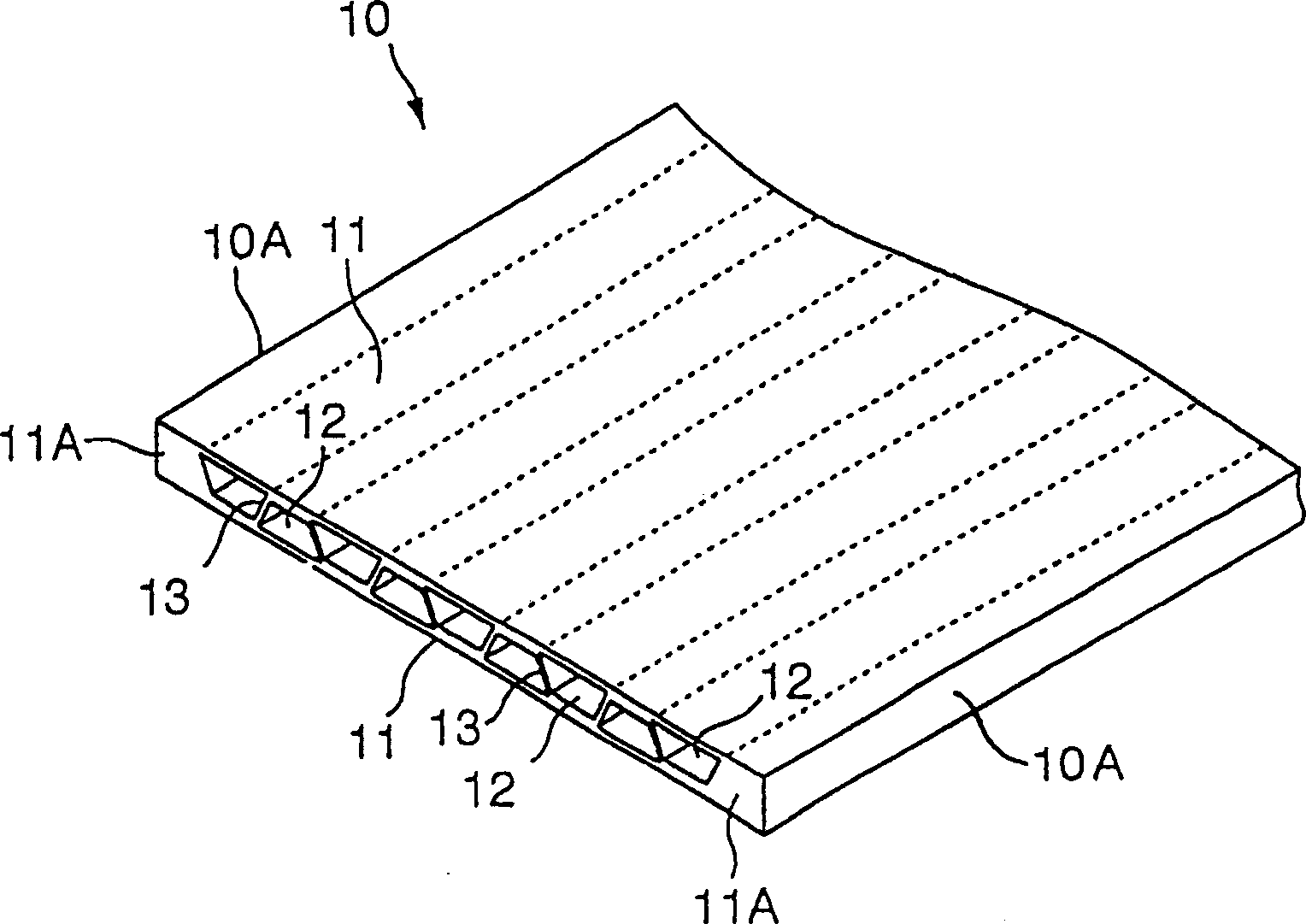

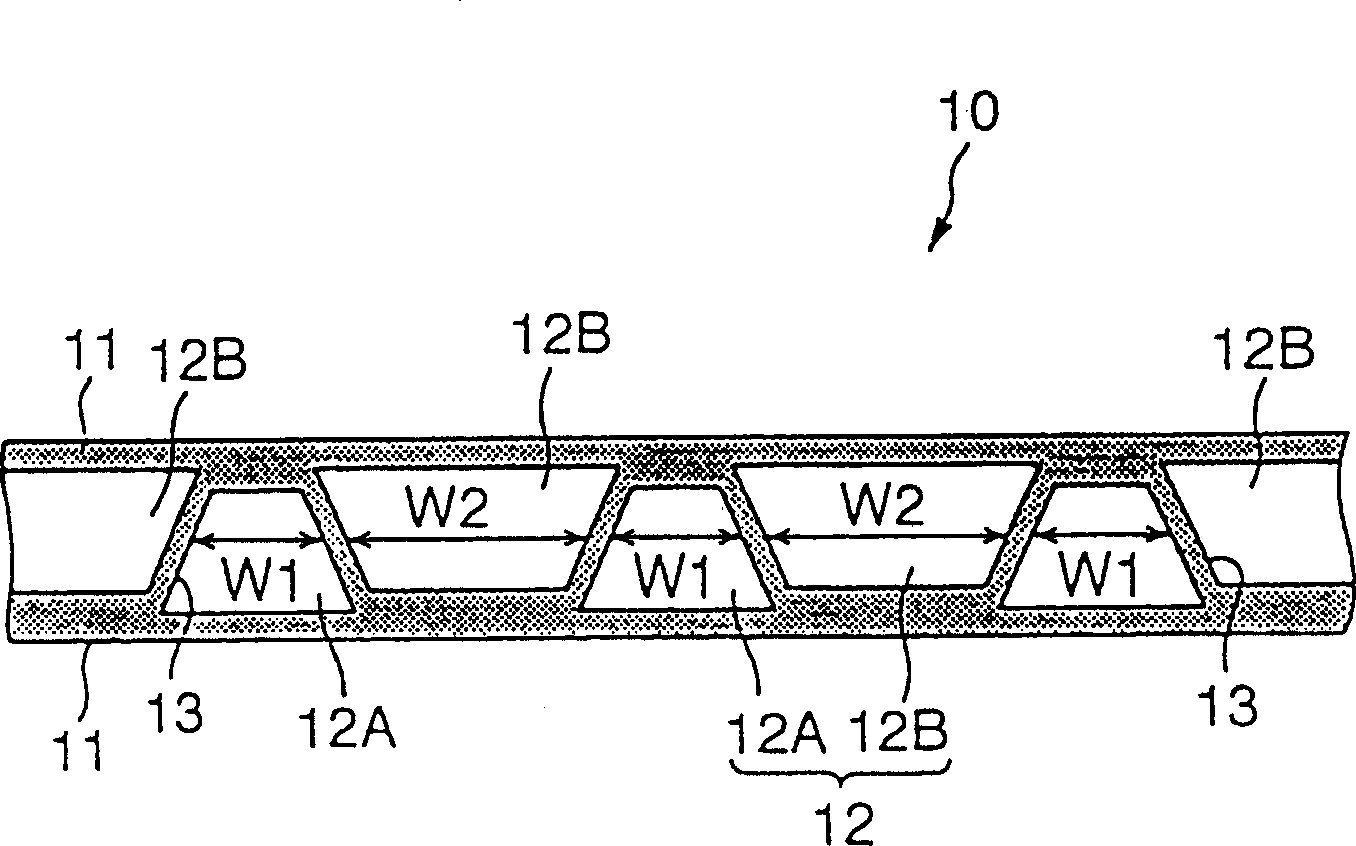

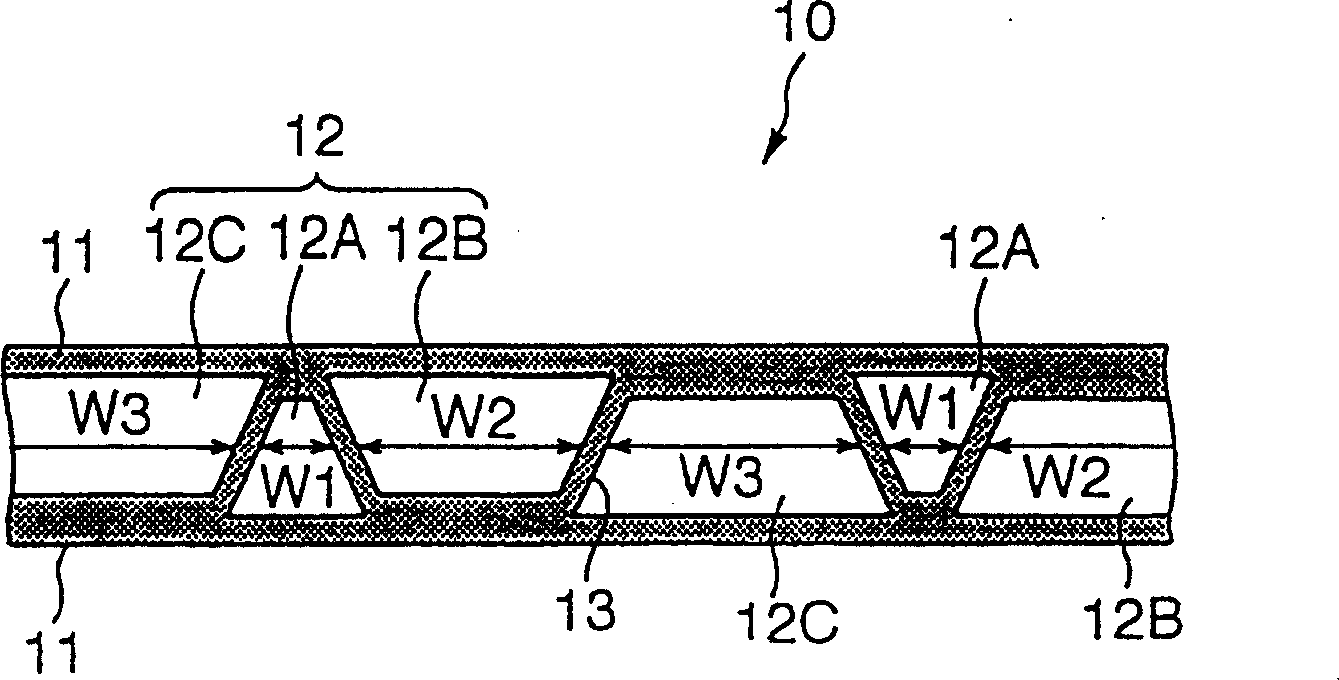

[0041] figure 1 is a schematic perspective view of a hollow panel according to the first embodiment, figure 2 It is an end view of a part of the hollow plate. Referring to the accompanying drawings, a hollow panel 10 that can be used as a building material, such as wall panels, floors, and ceilings, includes: a pair of straight outer surfaces 11, which are substantially parallel to each other, and a plurality of hollow parts 12, which are placed on the Between the outer surfaces 11, they are arranged on substantially the same plane.

[0042] The shape of each hollow portion 12 is along the figure 2 Stretches linearly in the direction of the paper plane where it resides. The hollow portion 12 is formed so that the partition walls 13 arranged at predetermined intervals in the lateral direction in the figure are inclined at approximately the same angle, and in alternately different directions. As a result, each hollow portion 12 is approximately trapezoidal in shape. In th...

no. 2 example

[0047] Figure 4 It is the second embodiment of the present invention. This embodiment is characterized in that, although the hollow parts 12 have the same cross-sectional area, different thicknesses T1 and T2 of the partition walls 13 between these hollow parts 12 are present alternately. The thickness is set to satisfy the relationship: T1>T2.

[0048] Also in the second embodiment, the area of thickness T1 has higher surface density or rigidity than the area of thickness T2. Therefore, this embodiment has a structure in which the resonant frequency of the panel is not uniform on the plane of the hollow panel 10, and has the same sound insulation effect as the first embodiment.

no. 3 example

[0050] Figure 5 with 6 It is the third embodiment of the present invention. This embodiment is characterized in that a solid portion 15 is formed in a specific area of the initially formed hollow portion. Such as Image 6 As shown, the solid portion 15 may be formed linearly in an area corresponding to a single hollow portion, or alternatively formed by extending to a plurality of hollow portions 12 . In the example shown, the solid portion 15 extends linearly. However, the way it stretches is not limited to the linear one. It can be said that this embodiment is realized by increasing the thickness of a specific partition wall 13 .

[0051] Also, this embodiment has the same effect as the previous embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com