Injectio moulding machine control method for reducing weight change of moulded product

A technology of injection molding machine and algorithm, which is applied in the field of control to reduce the weight change of molded products, and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

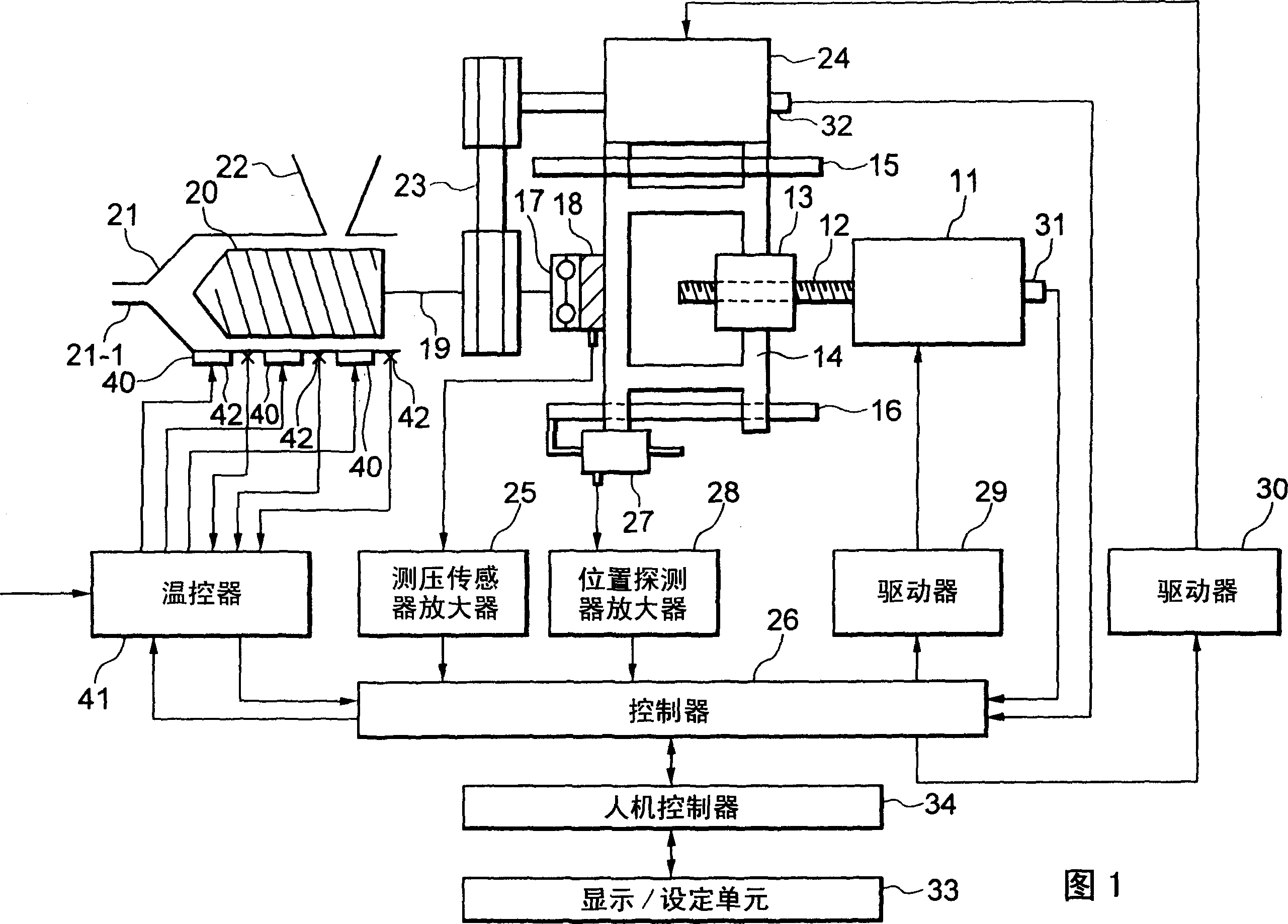

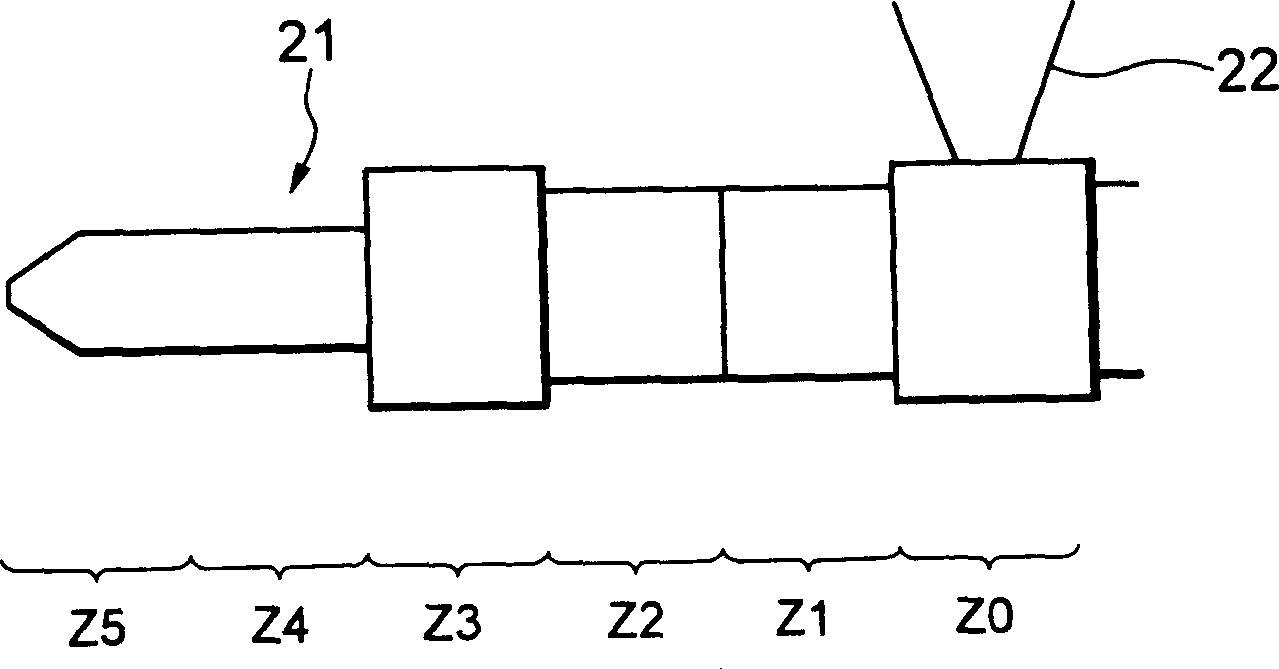

Embodiment Construction

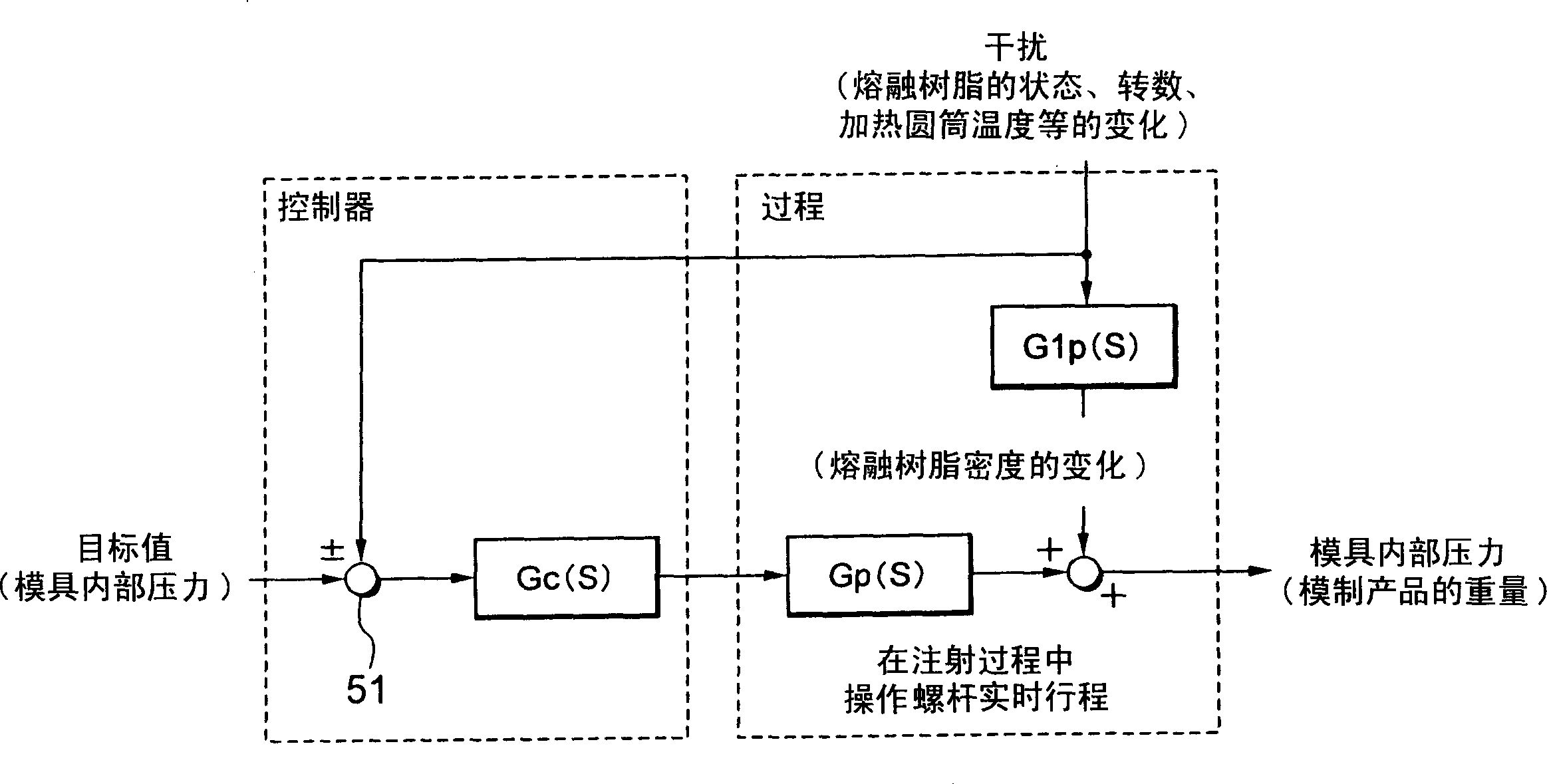

[0028] refer to Figure 4 , the mold internal pressure feed-forward control system of the first embodiment of the present invention will be described below. Figure 4 It is a block diagram of the mold internal pressure feed-forward control system of the present invention. In the present invention, as Figure 4 As shown, a feedback control system 60 is added to combine image 3 described in the feed-forward control system.

[0029] The feedback control system 60 is used to feed back the change of the molten resin measured by the measuring device for measuring the density of the molten resin. The feedback control system 60 operates during the injection molding process and is designed to eliminate the uncertain effects found in conventional systems by minimizing changes in the density of the molten resin by the feedback control system 60 before the injection process begins.

[0030] More specifically, he said that in the feedback control system 60, any one of the number of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com