Variable speed device for internal conbustion engine

A speed change device and internal combustion engine technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of uncoordinated operators and different shift loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

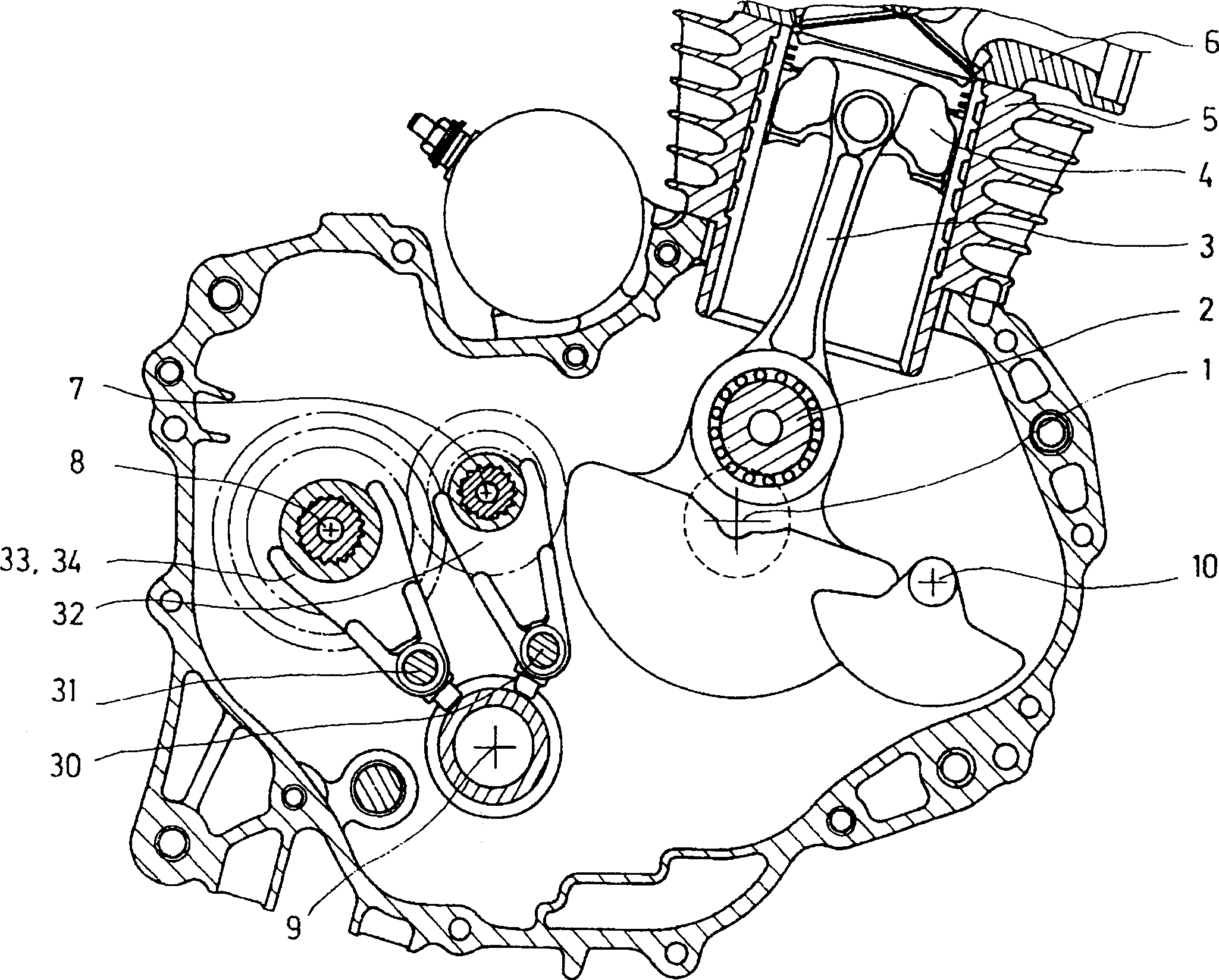

[0031] figure 1 It is a cross-sectional view of the main part of the air-cooled internal combustion engine for motorcycles according to the present invention, viewed from the right side, cut with a front-to-rear surface. In the figure, 1 is a crankshaft, 2 is a crankshaft pin of the crankshaft, 3 is a connecting rod connected with the crankshaft pin 2, and 4 is a piston connected with the connecting rod 3, which moves up and down in the cylinder part 5. A cylinder head 6 is connected to the upper part of the cylinder member 5. 7 is the main shaft of the transmission adjacent to the crankshaft 1, 8 is the secondary shaft of the transmission adjacent to it, 9 is the shift drum, and 10 is the balance shaft .

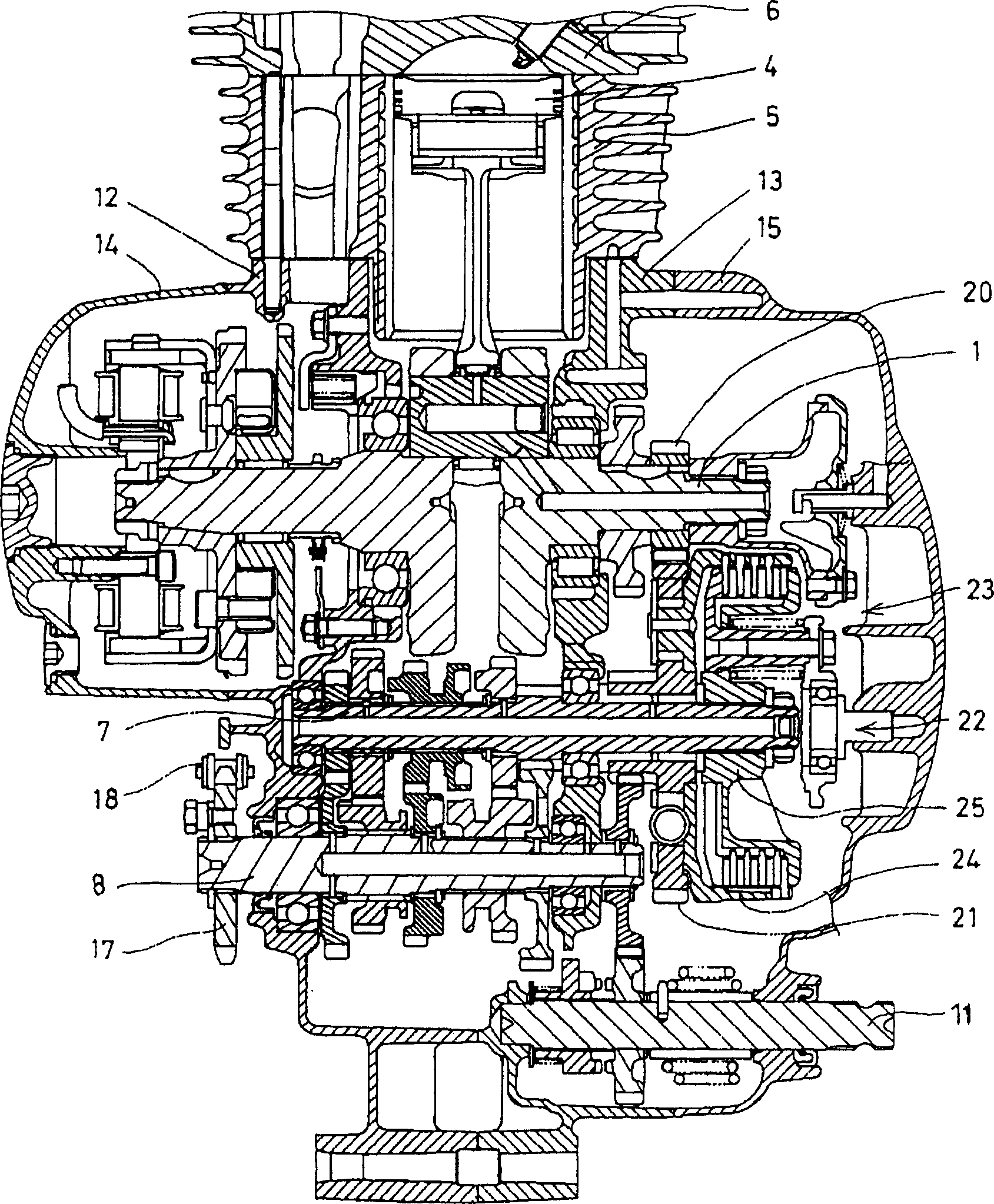

[0032] figure 2 It is a cross-sectional view of the main part of the internal combustion engine as seen from the rear after cutting the main parts of the above-mentioned internal combustion engine through the lateral planes of the piston 4, the crankshaft 1, the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com