Heat absorption tube for solar energy

A technology of heat-absorbing pipes and solar energy, which is applied in the field, can solve problems such as inappropriateness, achieve the effect of reducing heat loss and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

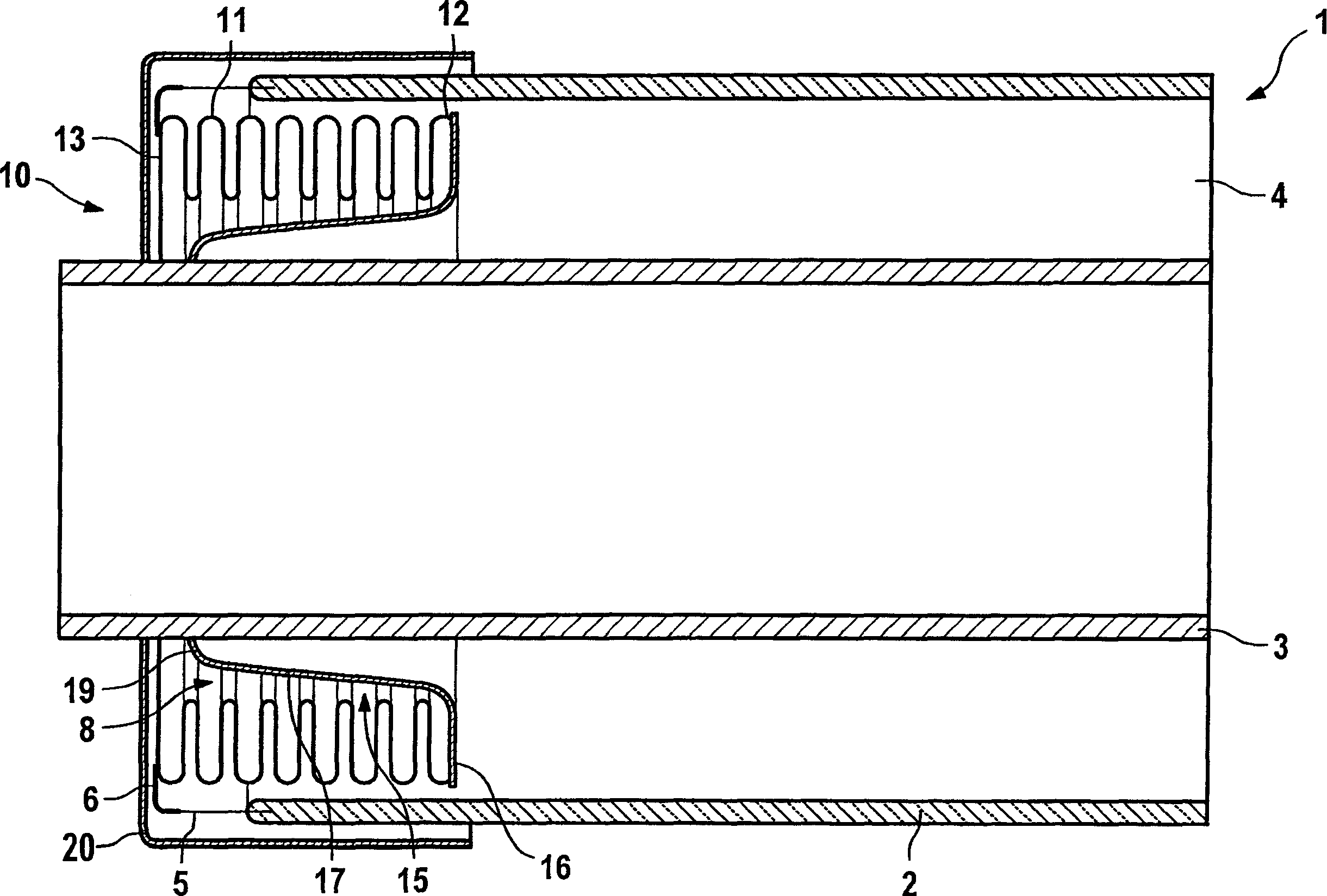

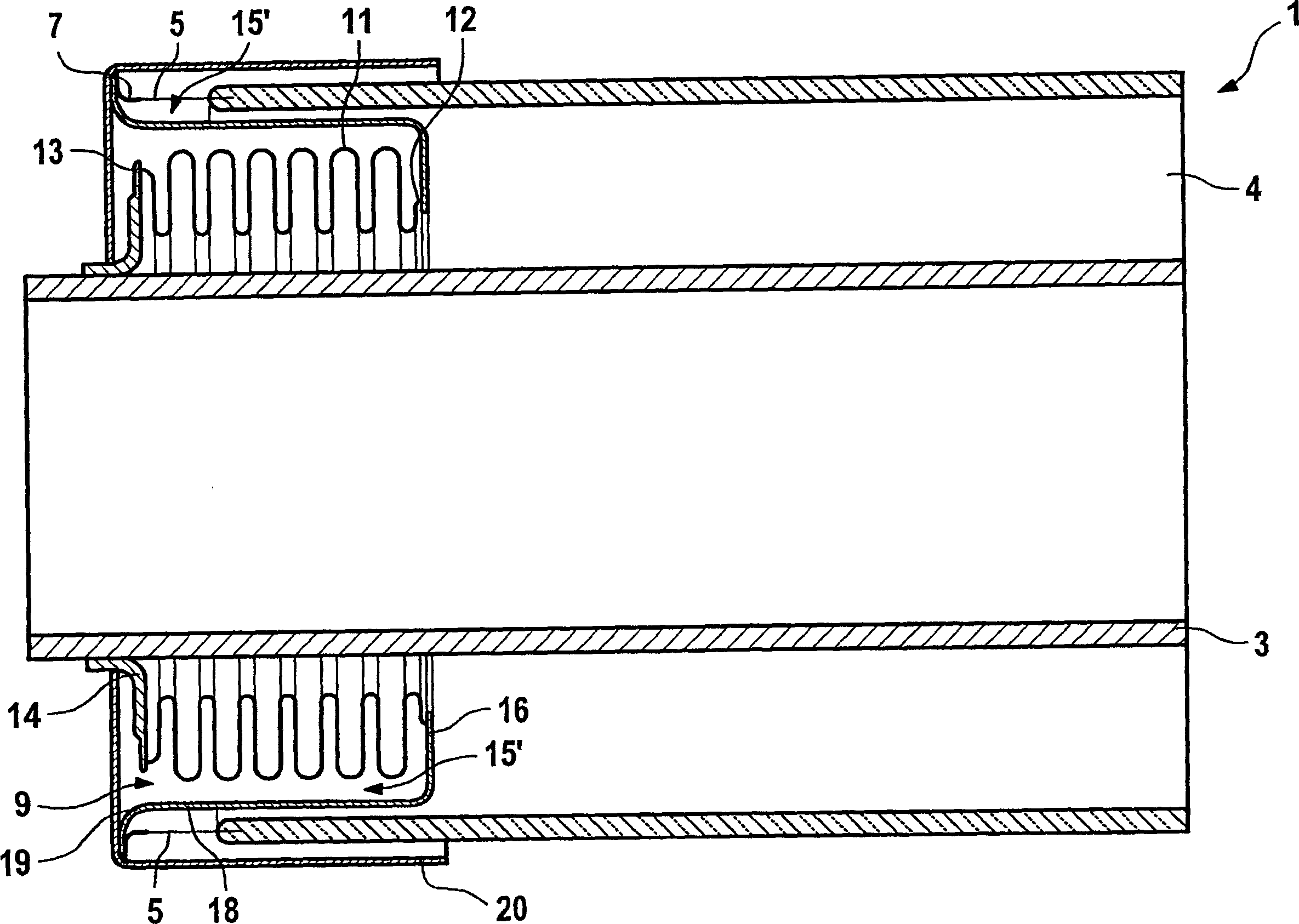

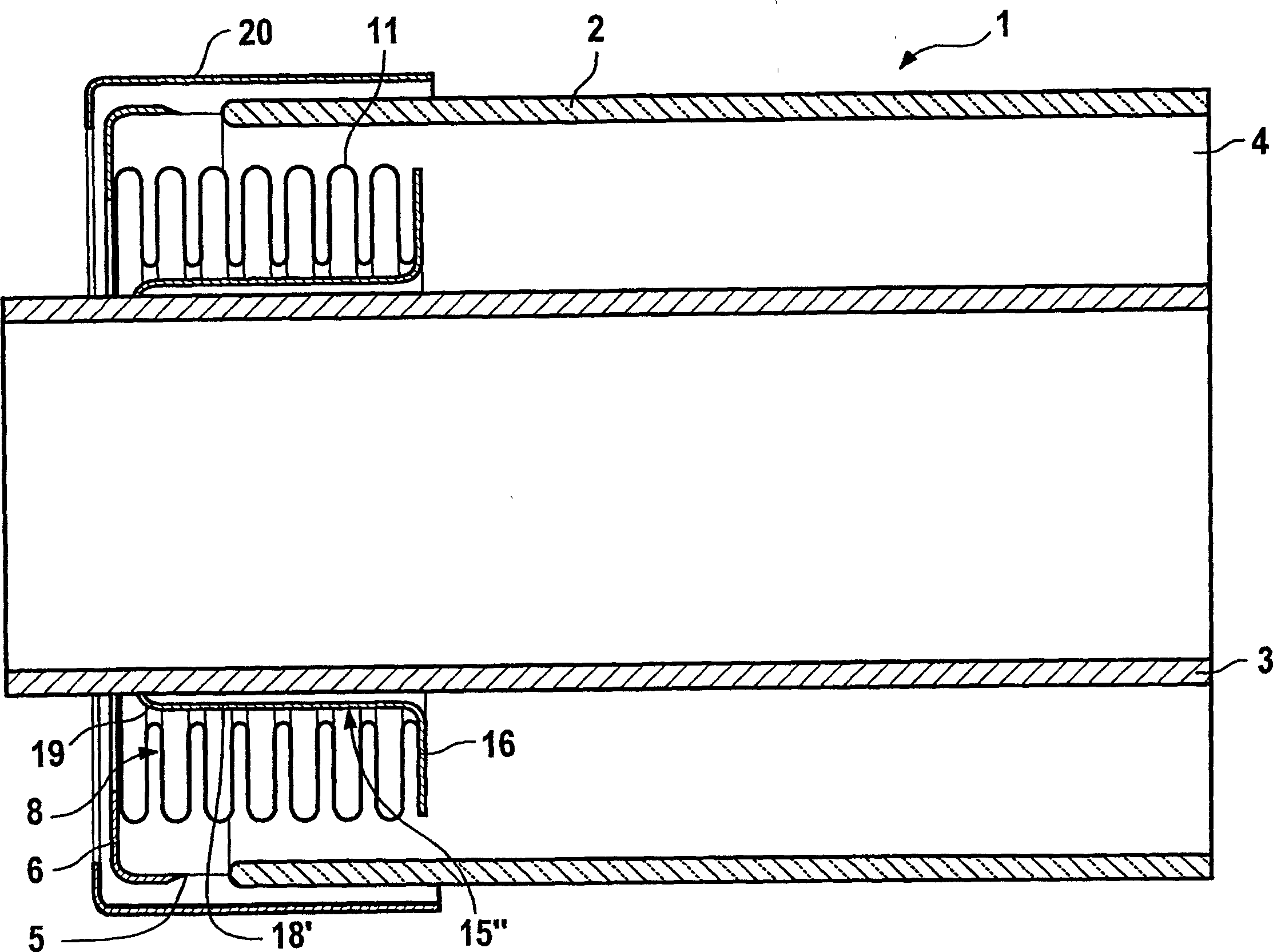

[0039] figure 1 The end of the heat absorber tube 1 is shown in section. The heat absorber tube 1 has a jacket tube 2 made of glass and a metal tube 3 arranged concentrically in the jacket tube 2 , which is coated on the outside with a radiation-selective coating that absorbs solar radiation.

[0040]At the end of the sleeve 2 on the free end side, a glass-to-metal transition piece 5 is fastened, which has a radially inwardly directed band. In the annular space 4 formed between the sleeve 2 and the metal tube 3 , an expansion compensation device 10 in the form of a bellows 11 is arranged, which is fastened with its outer end 13 to the strap 6 of the glass-to-metal transition piece 5 .

[0041] The corrugated tube 11 therefore extends below the glass-to-metal transition piece 5 into the annular space 4 and is fastened at the opposite end to a connecting piece 15 which has an annular disc 16 for this purpose. At its inner edge, the annular disc 16 merges into a conical section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com