One-step process for preparing gum

A technology for chewing gum and polymer, which is applied in the field of manufacturing chewing gum, can solve the problems of unavailability of chewing gum additives, poor degradation performance, environmental pollution, etc., and achieves the effects of shortening the manufacturing time, simplifying the method, and simplifying the storage management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

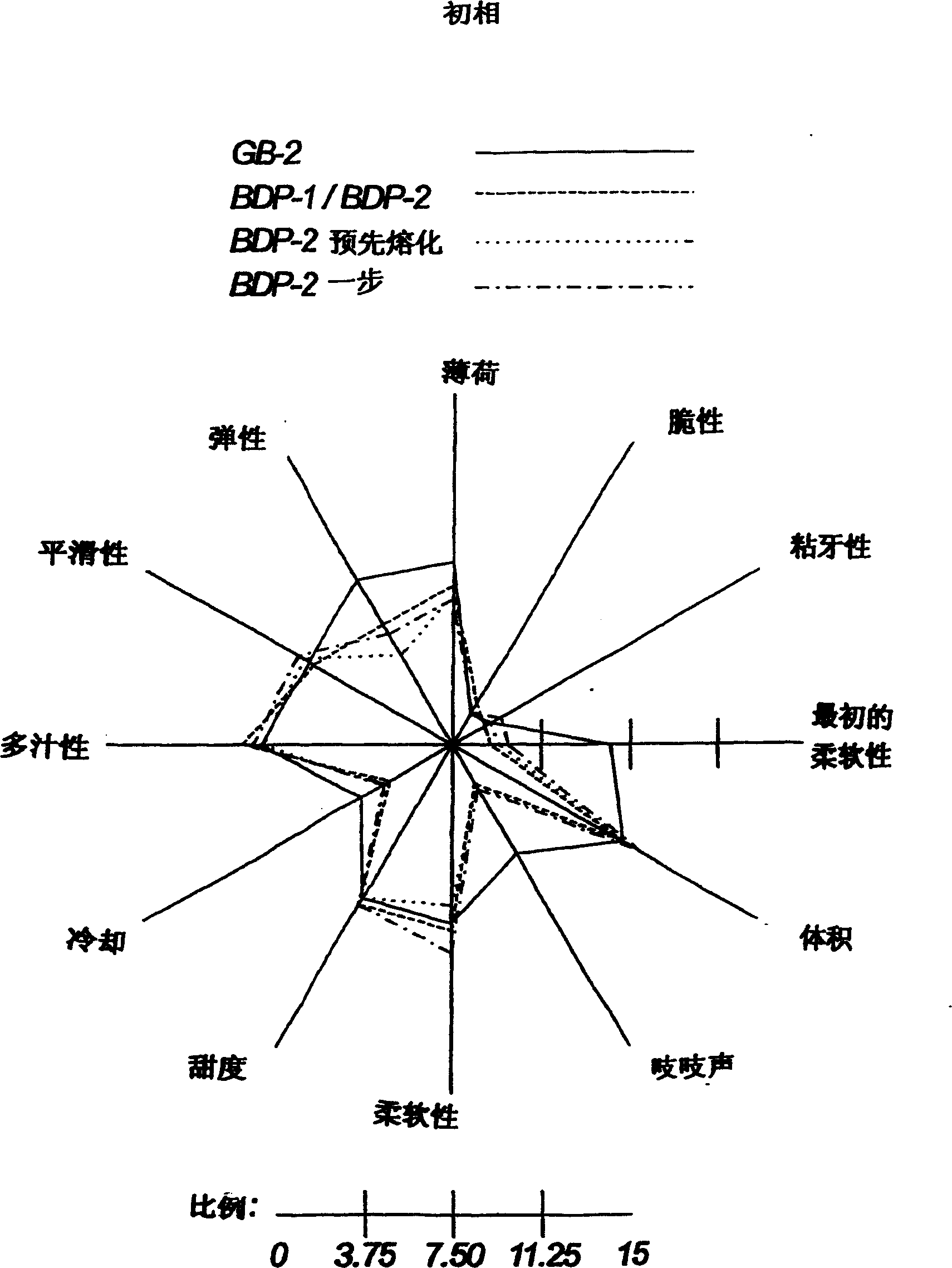

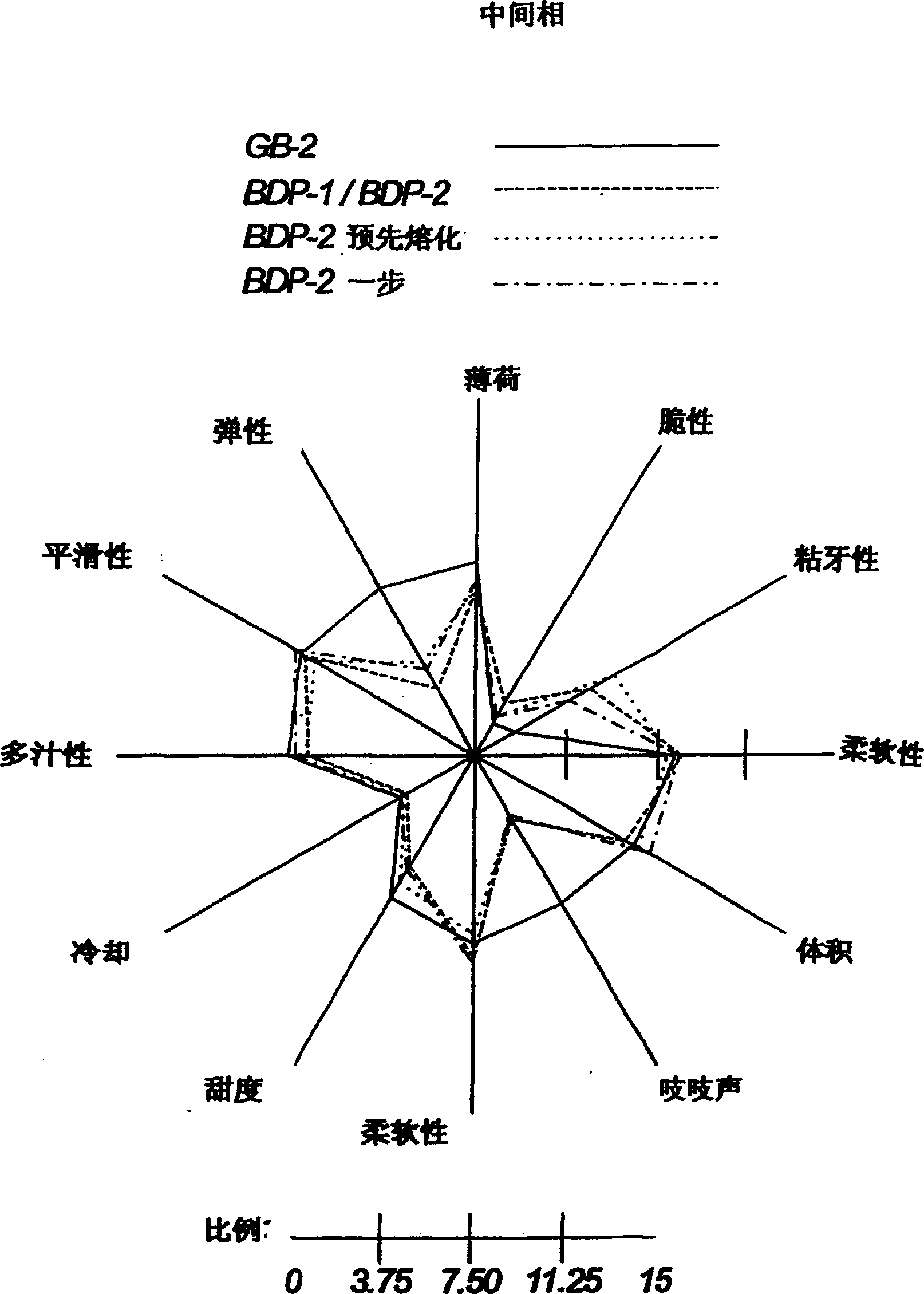

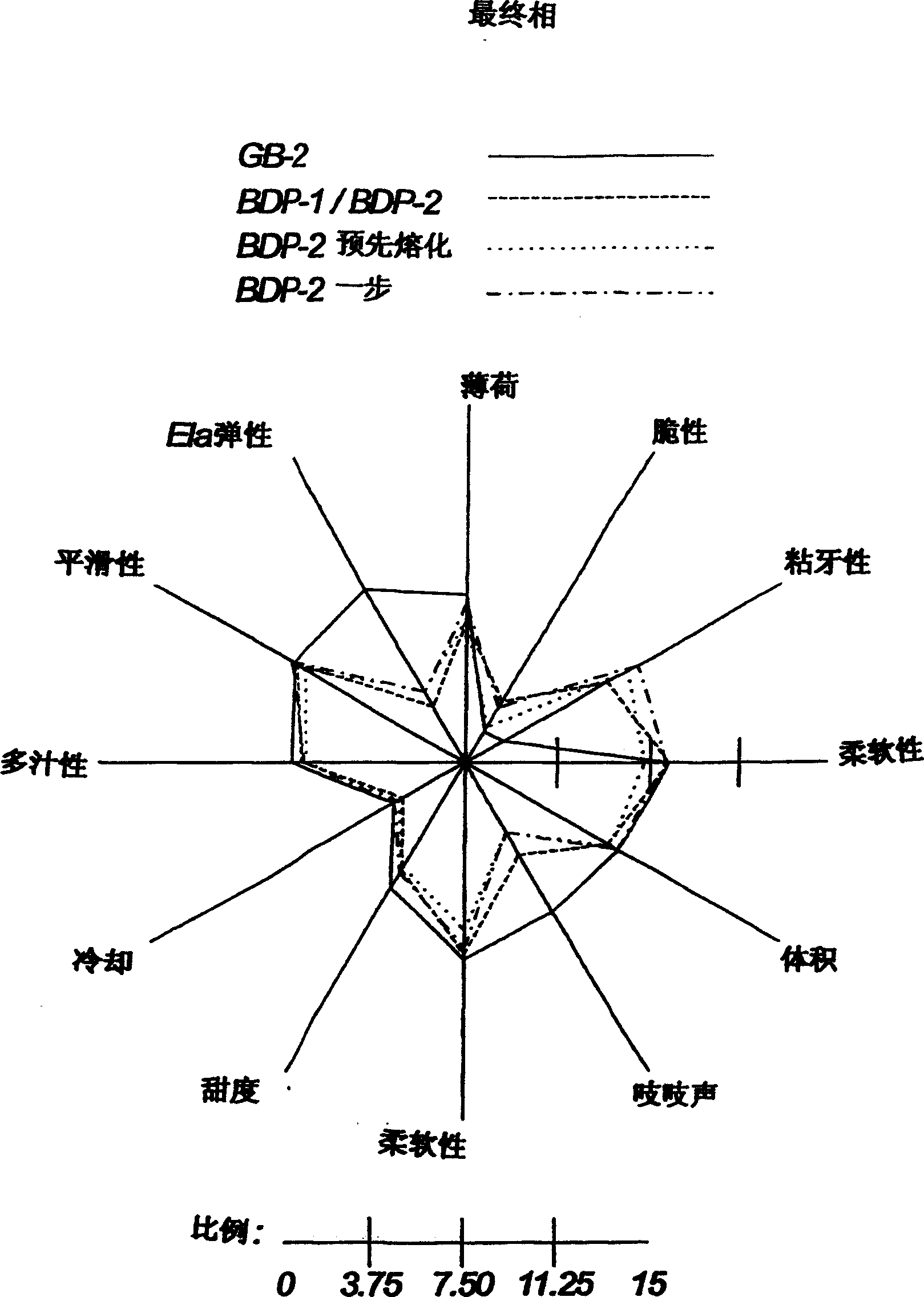

[0088] Chewing gums containing biodegradable gum base polymers were prepared using the traditional two-step process, in which the gum base was melted before mixing (reference test)

[0089] In this example, degradable polymers defined in US5672367 and obtained by cyclic esters and labile bonds capable of hydrolysis or breaking under the influence of light are used as part of the gum base. In the following, the polymer is referred to as BDP1, the gum base polymer was softened and melted in a water bath at 100°C for 30 minutes before the chewing gum additives listed below were mixed.

[0090] pre-melted gum base

[0091] Table 1 Composition and mixing conditions of preselected molten degradable gum base polymer BDP1

[0092] Composition Content (weight) Time (minutes) Temperature ℃

[0093] BDP1 40.46 0 60

[0094] Sorbitol powder 13.26 0 60

[0095] Lecithin 0.20 2 58

[0096] Hydrogenated glucose syrup 5.77 2 58

[0097] Sorbitol powder 13.46 2 58

[0098] Sorbitol powd...

Embodiment 2

[0109] Manufacture of mint-flavored chewing gums containing degradable gum base polymers by using a traditional two-step process in which the gum base is melted before mixing (reference test)

[0110] In this example, chewing gum was prepared essentially as described in Example 1, however, a different pre-melt degradation polymer BDP2 was used instead of BDP1, the ingredients and mixing conditions are shown in Table 2.

[0111] Table 2 Composition and mixing conditions with preselected molten degradable gum base polymer BDP2

[0112] Composition Content (weight) Time (minutes) Temperature ℃

[0113] BDP2 40.46 0 63

[0114] Sorbitol powder 13.26 0 63

[0115] Lecithin 0.20 2 63

[0116] Hydrogenated glucose syrup 5.77 2 63

[0117] Sorbitol powder 13.46 4 63

[0118] Sorbitol powder 13.46 6 63

[0119] Peppermint oil 1.54 6 63

[0120] Menthol (crystal) 0.31 7 63

[0121] Menthol powder 0.37 7 61

[0122] Peppermint oil powder 0.19 7 61

[0123] Menthol powder 0.19 8...

Embodiment 3

[0129] A mint flavored chewing gum containing non-degraded polymers was prepared according to the present invention using a one-step mixing process.

[0130] In this embodiment, the step of pre-melting the gum base is omitted, and the traditional gum base A is directly used, that is, without pre-melting, and mixed with chewing gum additives in the mixer used in Examples 1-2, as shown in Table 3 .

[0131] Table 3 Composition and one-step mixing conditions with non-degraded gum base A

[0132] Composition Content (weight) Time (minutes) Temperature 1 ℃

[0133] Gum base A 40.46 0 25

[0134] Sorbitol powder 13.26 0 25

[0135] Lecithin 0.20 2 38

[0136] Hydrogenated glucose syrup 5.77 2 38

[0137] Sorbitol powder 13.46 4 42

[0138] Sorbitol powder 13.46 5 42

[0139] Peppermint oil 1.54 6 43

[0140] Menthol (crystal) 0.31 6 43

[0141] Menthol powder 0.37 7 45

[0142] Peppermint oil powder 0.19 7 45

[0143] Menthol powder 0.19 7 45

[0144] Saccharin 0.19 8 45 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com