Technics of dual bags for planting shiitake

A flower mushroom and process technology, applied in the field of flower mushroom cultivation technology, can solve the problems of difficult water retention technology of flower mushroom sticks, deformation of the top, and self-drying of mushroom buds, so as to liberate labor productivity, improve shape and quality, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

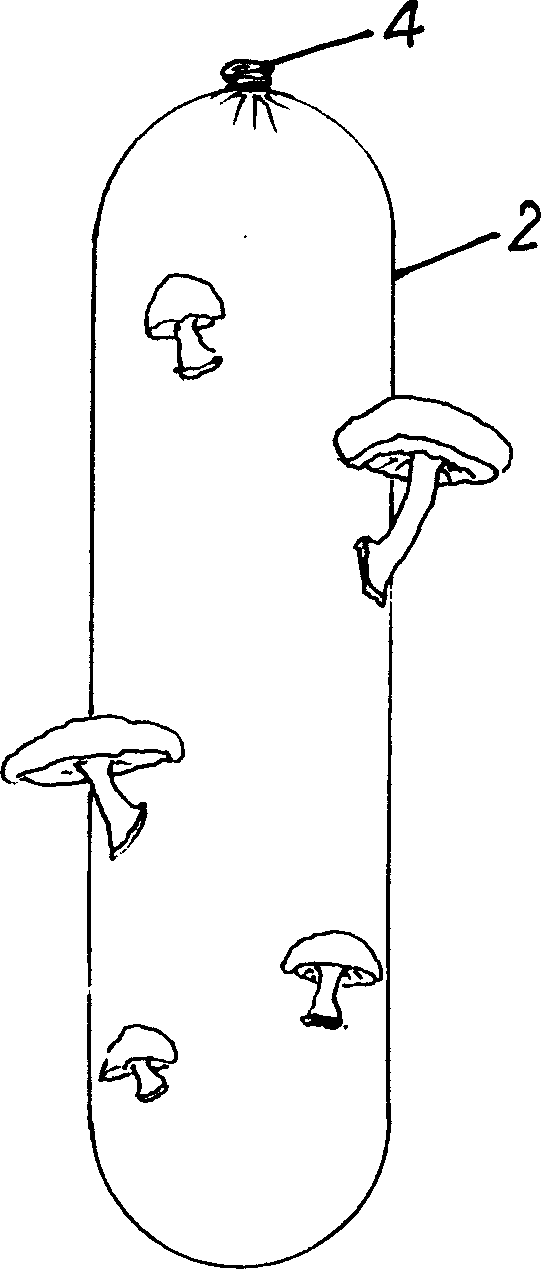

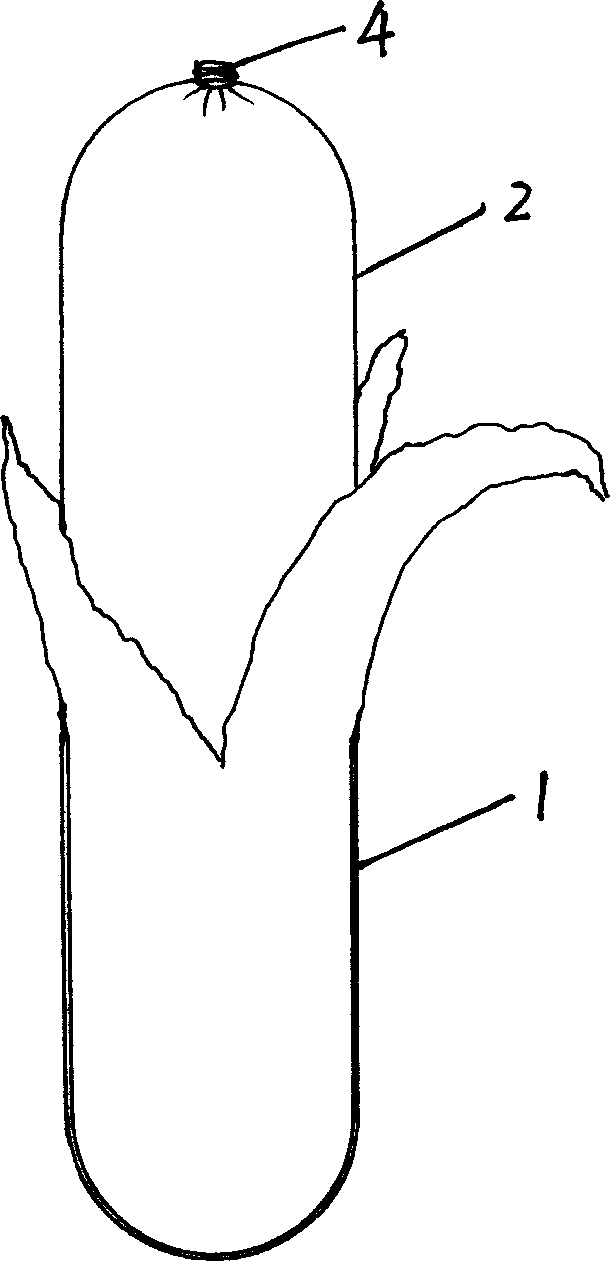

[0016] The present invention will be described in detail below according to the accompanying drawings.

[0017] 1. Batching and mixing process: in the compost, miscellaneous wood chips account for 78%, wheat bran accounts for 20%, sucrose and gypsum each account for 1%. These raw materials are required to be free from mildew, adulteration, and deterioration. During production, the various raw materials are weighed according to the formula, and water is added to mix well. The moisture content of the compost is preferably about 60%. About 100 bags (sections) of 100kg compost are produced in the southern production area; about 50 bags (section) are produced in the northern production area;

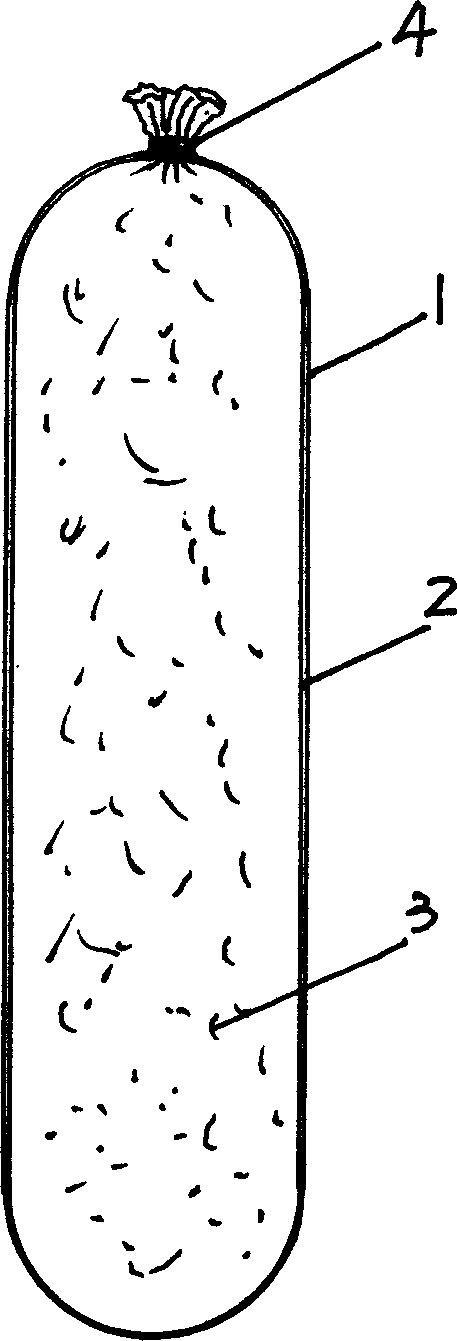

[0018] 2. Bagging process: When bagging the culture material (3), first put the plastic degradable water-retaining film (bag) (2) on the barrel of the bagging machine, and then cover the bag (2) with conventional cultivation bag (1), two bags are merged together, and the culture material (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com