Electrooptical device and electronic appliance

An electro-optic device and electrode technology, which is applied in the direction of electric light source, identification device, lighting device, etc., can solve the problems of difficulty in meeting, uneven display, and inability to form a sufficiently large storage capacitor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The following embodiments are embodiments in which the electro-optical device of the present invention is applied to a liquid crystal device.

[0081] (Constitution of the pixel part)

[0082] First, see Figure 1 to Figure 4 The configuration of the pixel portion of the electro-optical device according to Embodiment 1 of the present invention will be described.

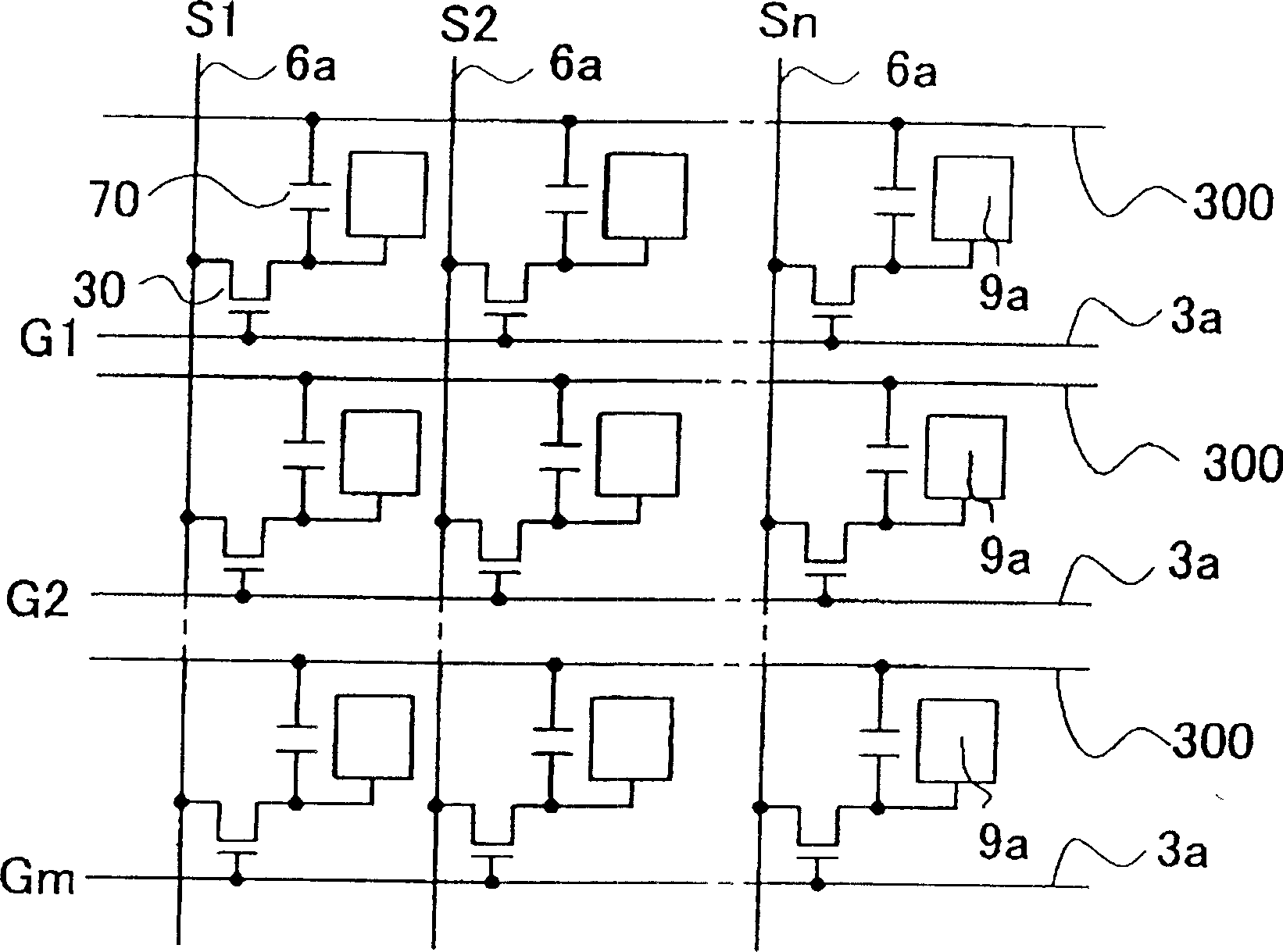

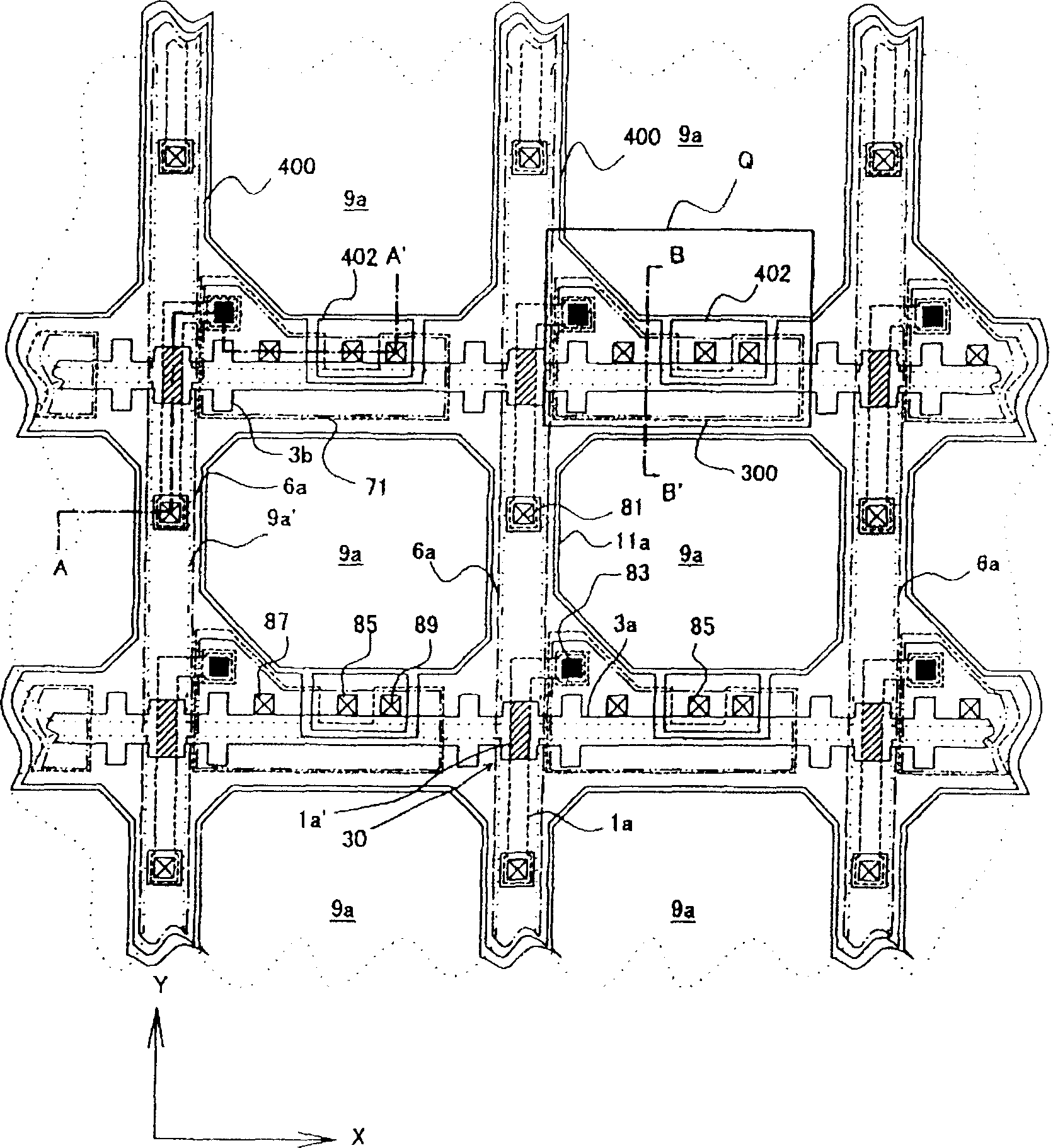

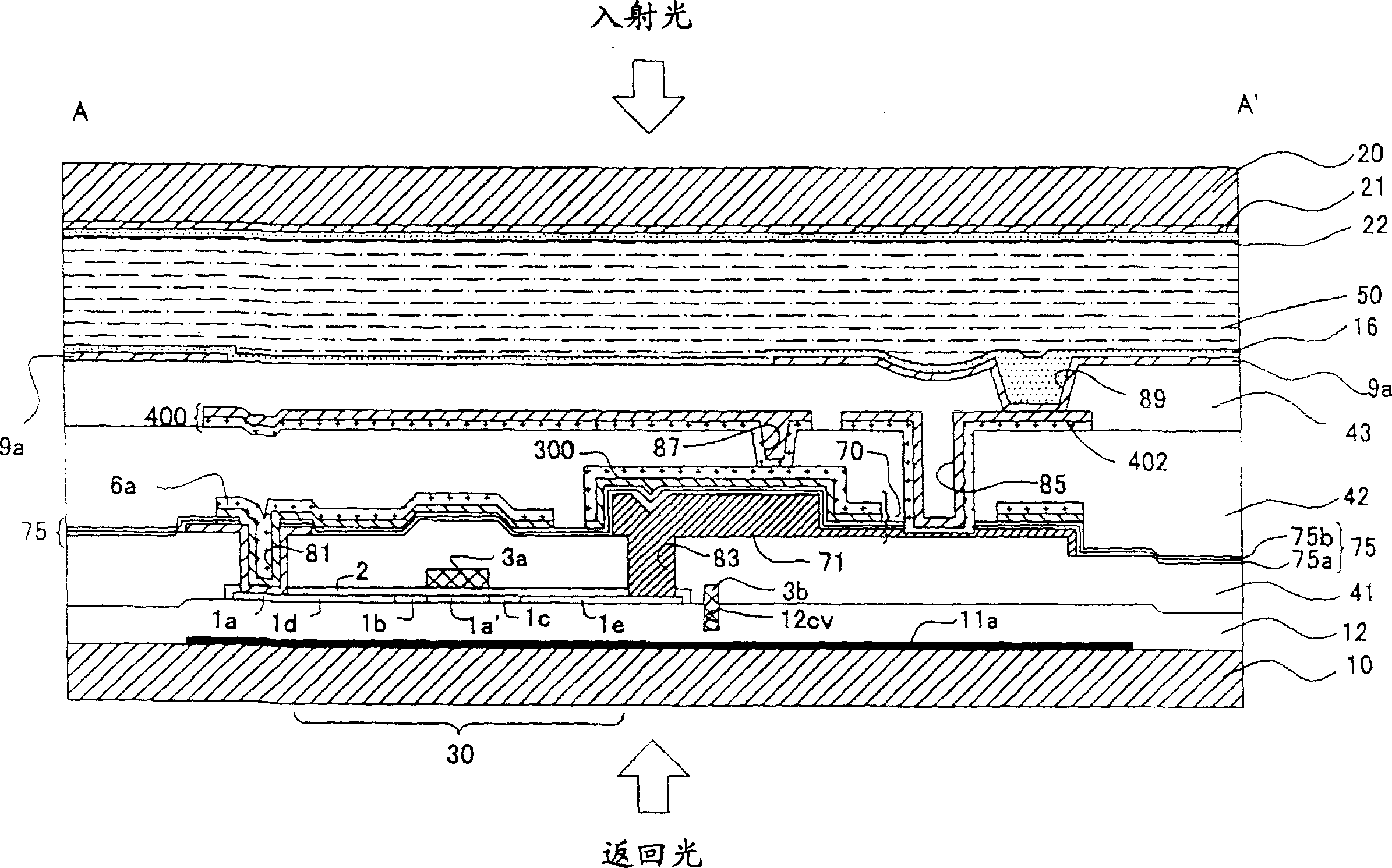

[0083] figure 1 is a circuit diagram showing an equivalent circuit of various elements, wiring, and the like provided on a plurality of pixels formed in a matrix forming an image display region of an electro-optical device. figure 2 It is a plan view of a plurality of adjacent pixel groups of a TFT array substrate on which data lines, scanning lines, pixel electrodes, etc. have been formed. image 3 yes figure 2 The A-A' profile, Figure 4 yes figure 2 The B-B' profile. In addition, in image 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com