Pipe for cable

A cable, linear technology, applied in the field of pipes for cables, which can solve the problems of influence, unsatisfactory welding process, the use of complex devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

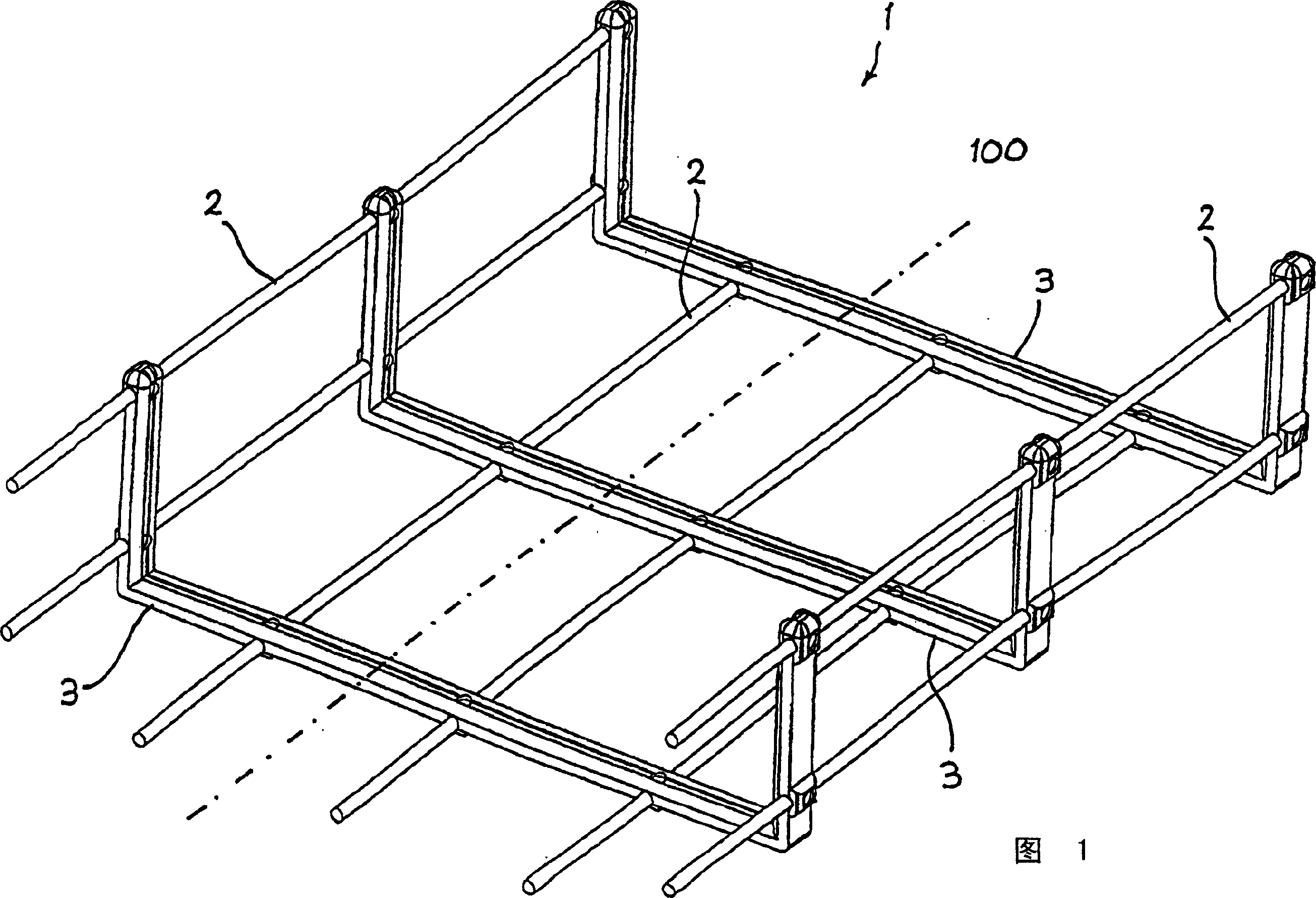

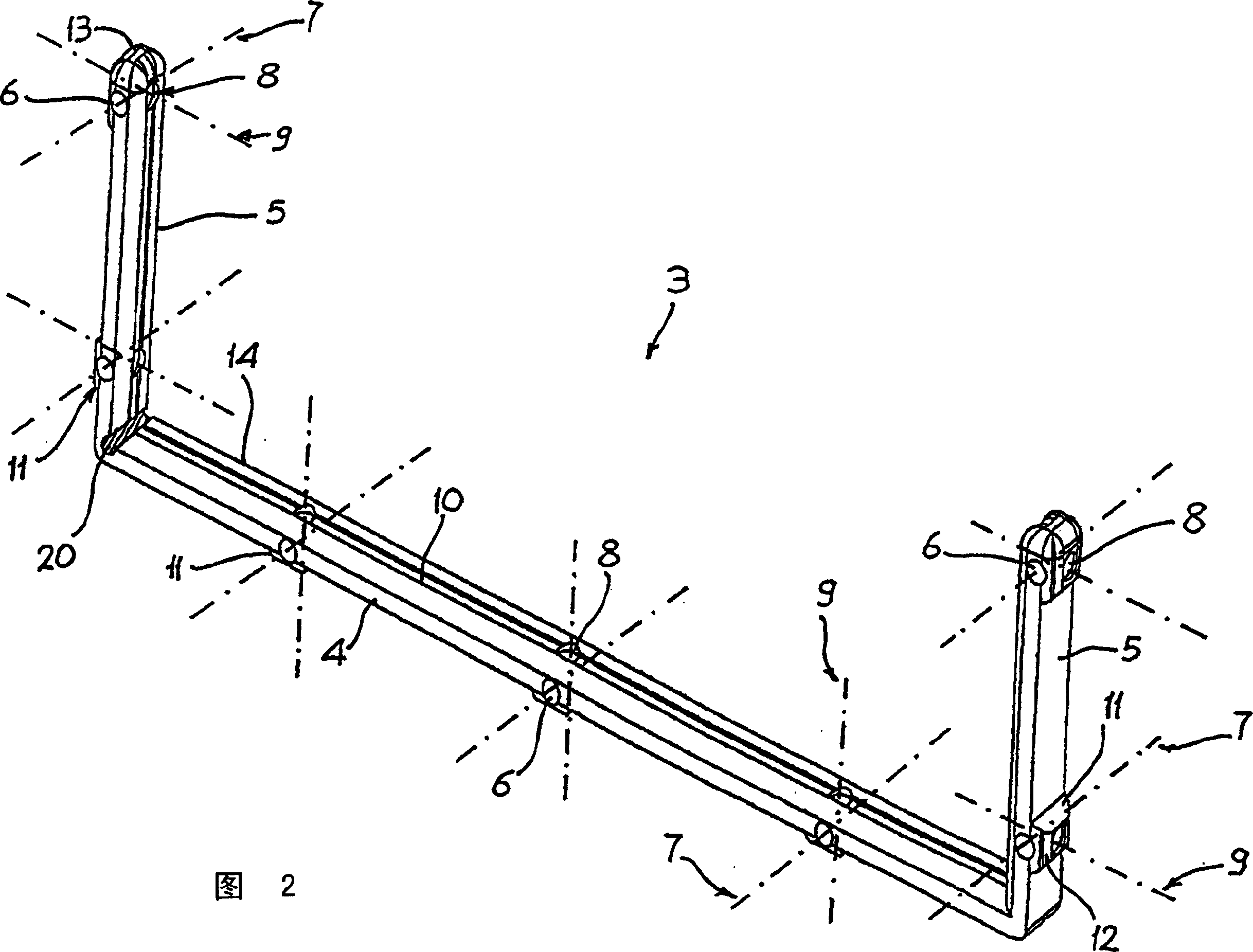

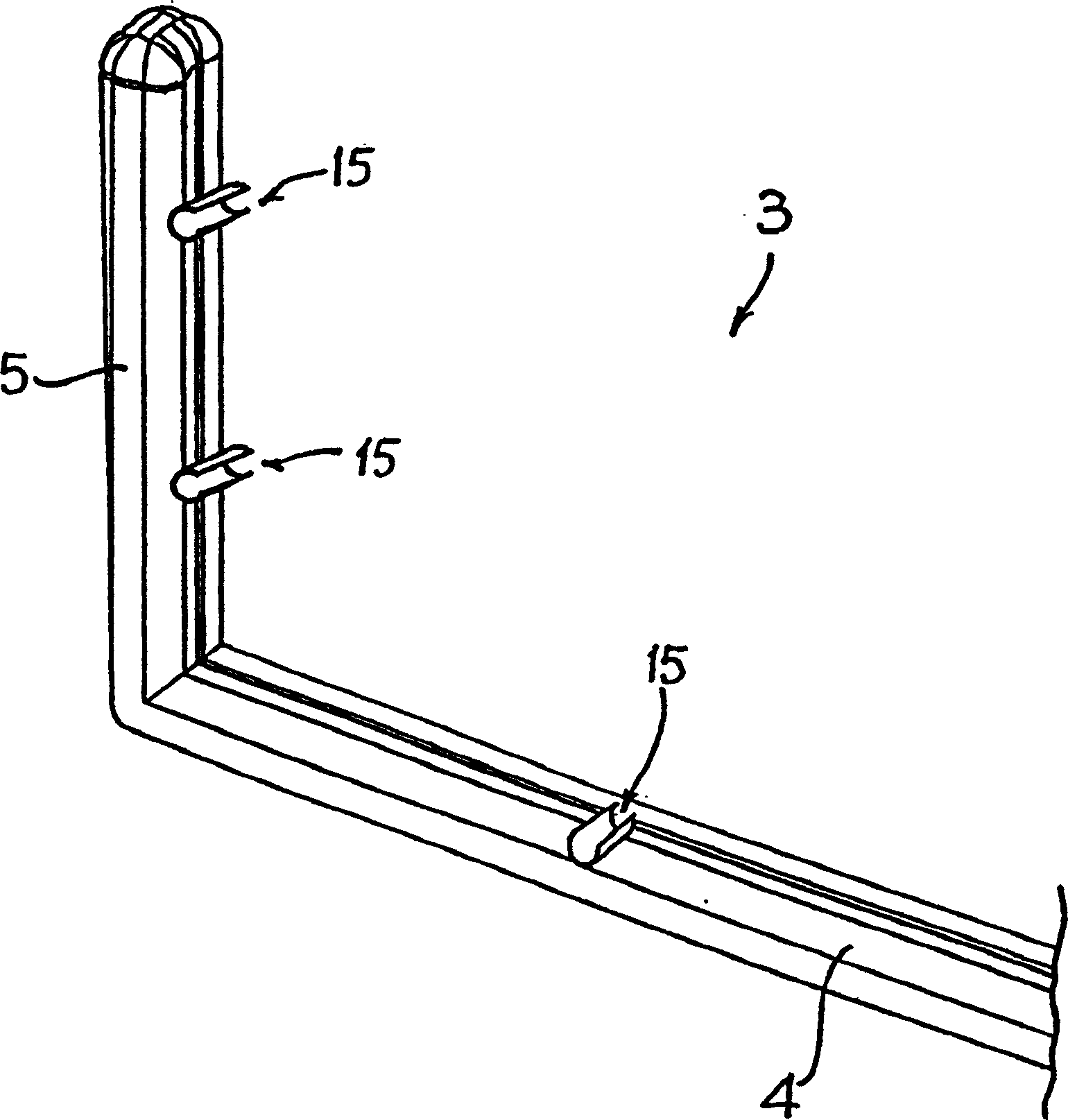

[0022] With reference to the above-mentioned accompanying drawings, the pipe for electric cables of the present invention is indicated by reference numeral 1 as a whole, and it comprises a plurality of linear metal parts 2 placed substantially parallel to each other, which extend longitudinally along the pipe in a straight or similar manner. , the longitudinal direction is represented by axis 100 in FIG. 1 . In the embodiment represented in FIG. 1, the wire-shaped part 2 is generally formed by a metal wire with a circular cross-section, or, in an equivalent manner, the wire 2 can be manufactured with different cross-sections, for example square, rectangular , or other shapes suitable for the application.

[0023] Preferably, the tube 1 for electrical cables comprises, at least in its longitudinal part length, a plurality of structural components 3, which are operatively connected to the linear part 2 according to the pattern, which will be explained in detail later in the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com