Process for producing granular tea

A production process and granulated tea technology, applied in the field of granulated tea production technology, can solve the problems of lag in processing methods and hinder the development of tea, and achieve the effects of reducing production costs, enhancing product market competitiveness, and improving tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

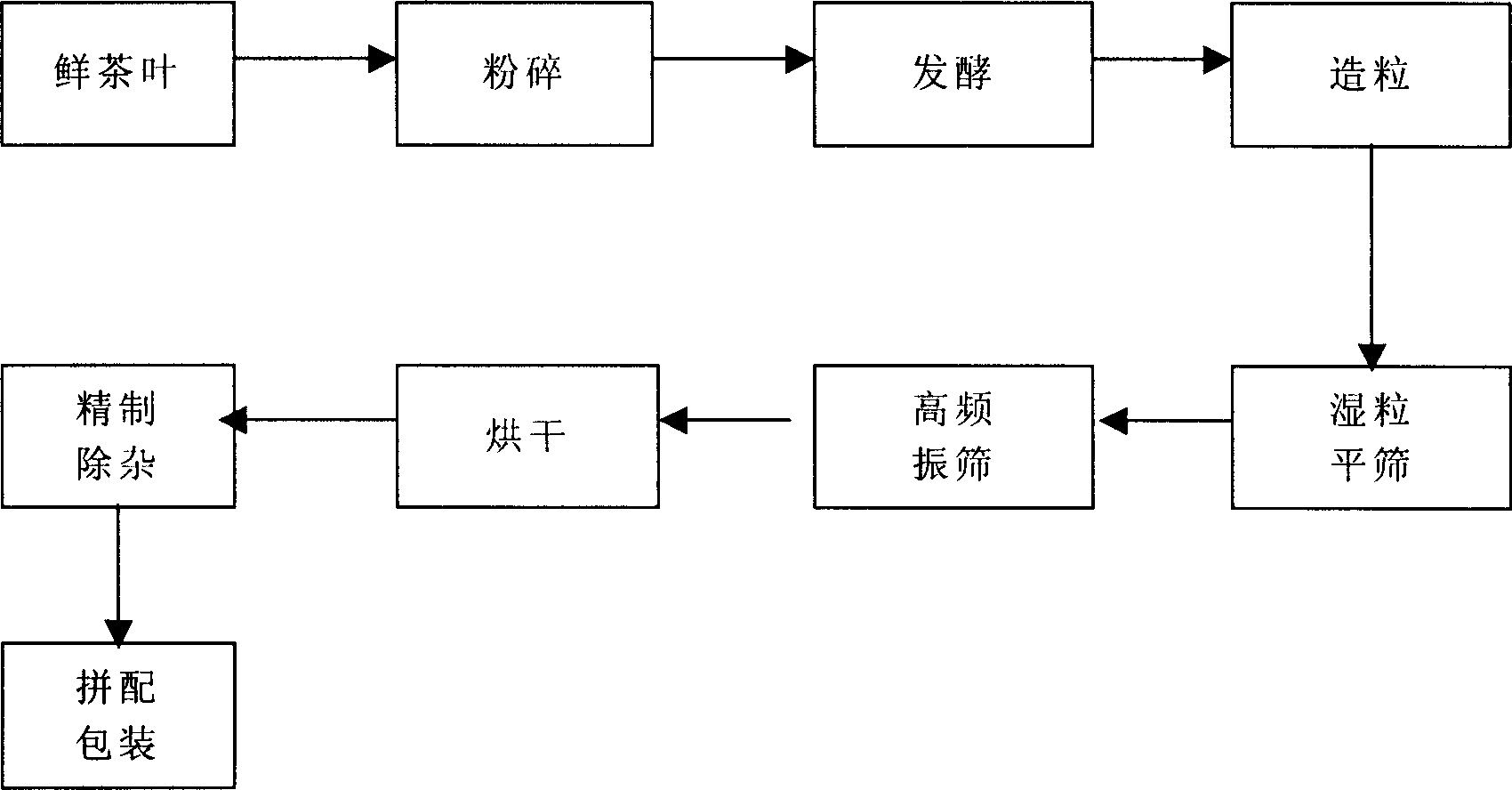

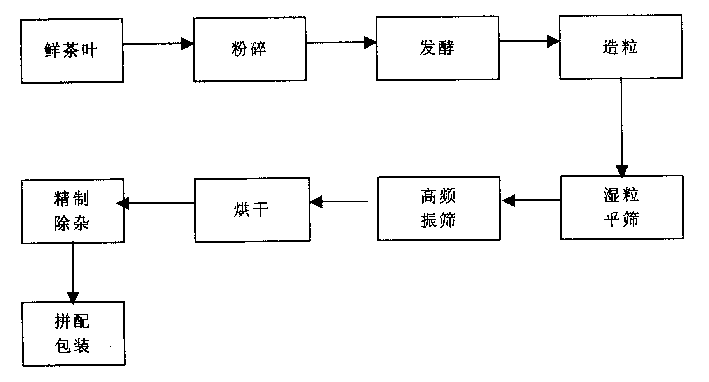

[0026] see figure 1 , adopt the processing step of the present invention to produce black tea as:

[0027] 1. Picking fresh tea leaves

[0028] Two, smash

[0029] 3. Fermentation

[0030] 4. Granulation

[0031] 5. Wet grain flat sieve

[0032] 6. High frequency vibrating screen

[0033] 7. Drying

[0034] 8. Refining and impurity removal

[0035] 9. Blending and packaging

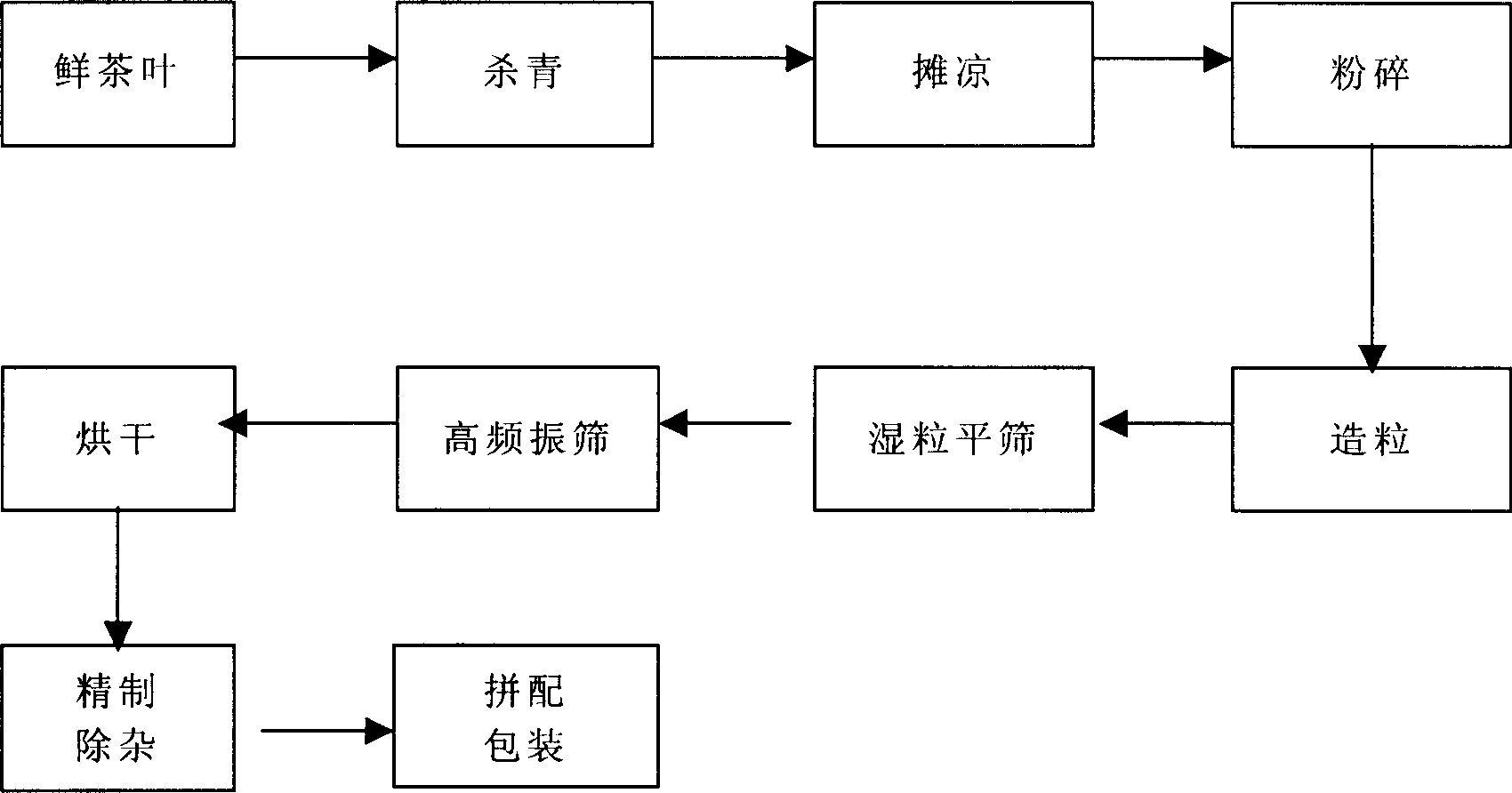

[0036] ginseng figure 2 , adopt the processing step of the present invention to produce green tea to be:

[0037] 1. Picking fresh tea leaves

[0038] 2. High temperature finishing

[0039] Three, cool breeze

[0040] 4. Crush

[0041] 5. Granulation

[0042] 6. Wet grain flat sieve

[0043] 7. High frequency vibrating screen

[0044] Eight, drying

[0045] Nine, refined impurity removal

[0046] 10. Blending and packaging

[0047] The above-mentioned granular tea processing steps, quality control points and technical requirements:

[0048] 1. Tea fermenting or cooling in the breeze: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com