Oil separator device of piston ring air channeling

A technology of piston rings and oil separators, applied in the direction of machine/engine, engine lubrication, engine components, etc., can solve problems such as air pollution, exhaust deterioration, and reduction of lubricating oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

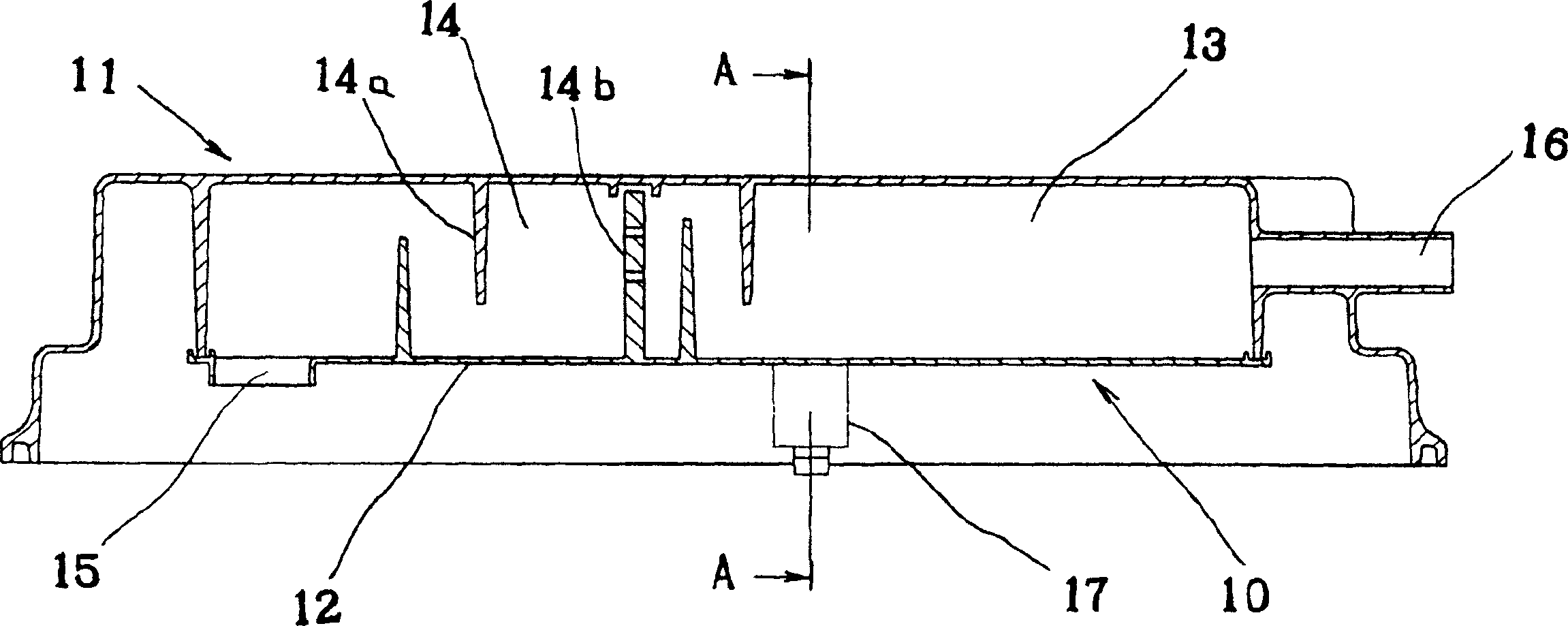

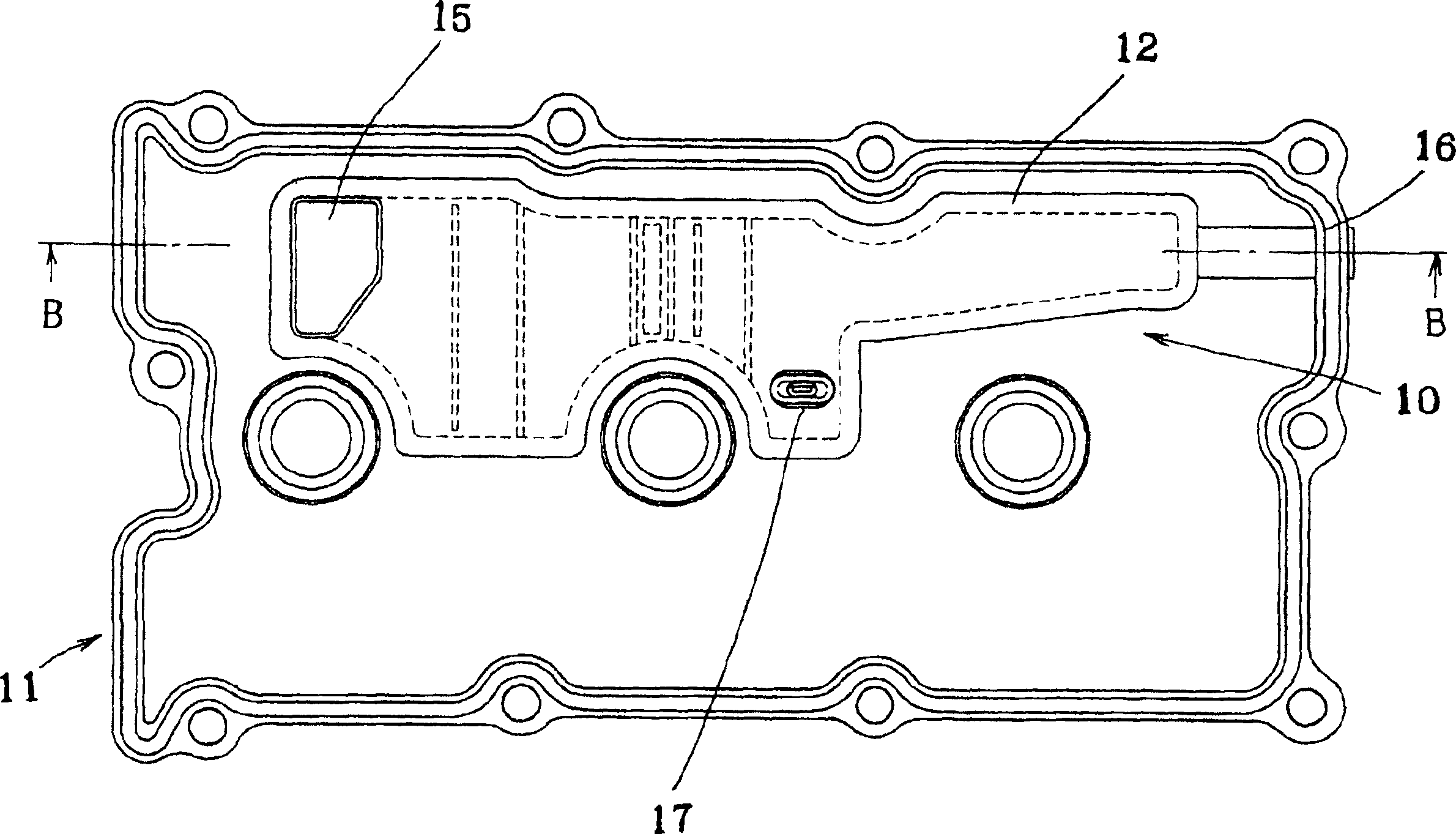

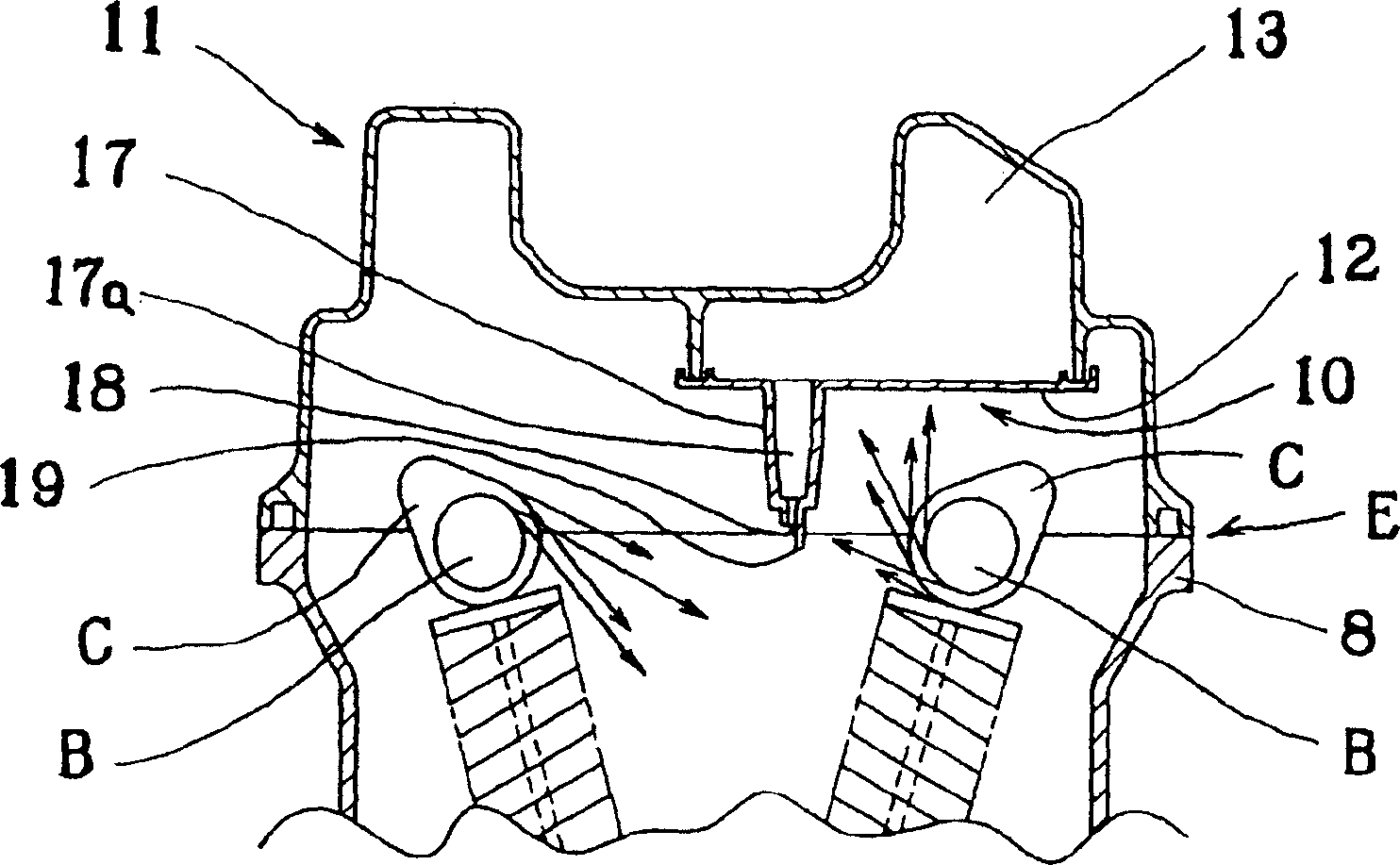

[0017] figure 1 In Fig. 4, the oil separator device 10 of the present invention is formed in a box-shaped cylinder head cover 11 which is formed of polyamide resin containing glass fibers and has an open bottom, and is fixedly installed from the inside of the cylinder head cover. The upper wall begins to divide the inner bottom cover body 12 at intervals, and a lubricating oil separation chamber 13 is formed between the bottom cover body 12 and the upper wall of the cylinder head cover 11 . Inside the lubricating oil separation chamber 13, a lubricating oil separating device 14 is arranged in a labyrinthine manner with a partition plate 14a and a perforated plate 14b, and a piston ring blow-by gas inlet 15 is set on one side of the bottom cover body 12, and on the other side One side is provided with a tubular outlet 16 penetrating the side wall of the cylinder head cover 11, and on the bottom cover 12, an oil discharge pipe 17 is hung down, and the oil discharge pipe 17 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com