Printed circuit board computer board making system

A technology for printed circuit boards and red copper plates, applied in the system field, can solve the problems of expensive printing equipment, and achieve the effects of convenient design, improved plate-making accuracy, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

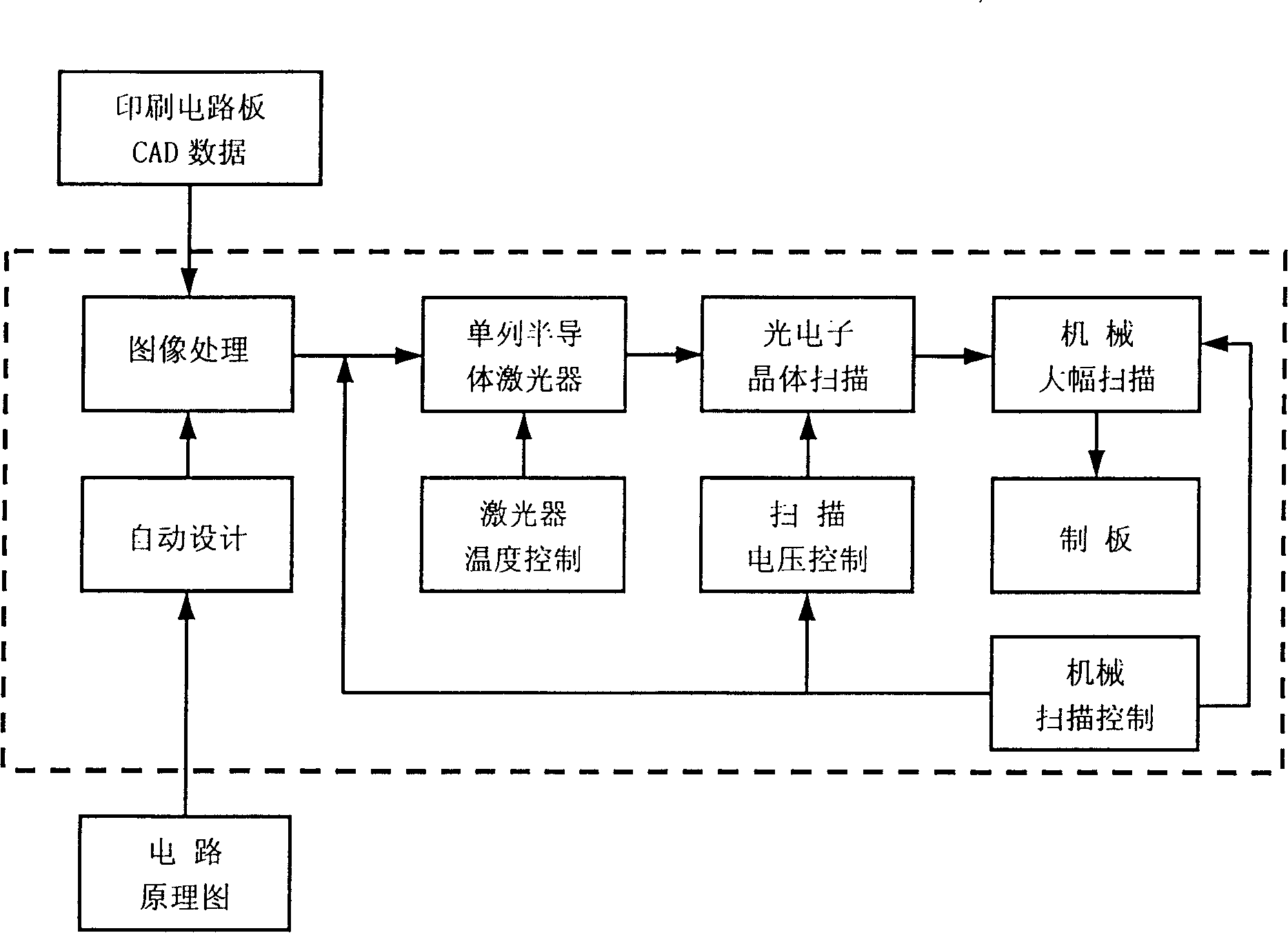

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

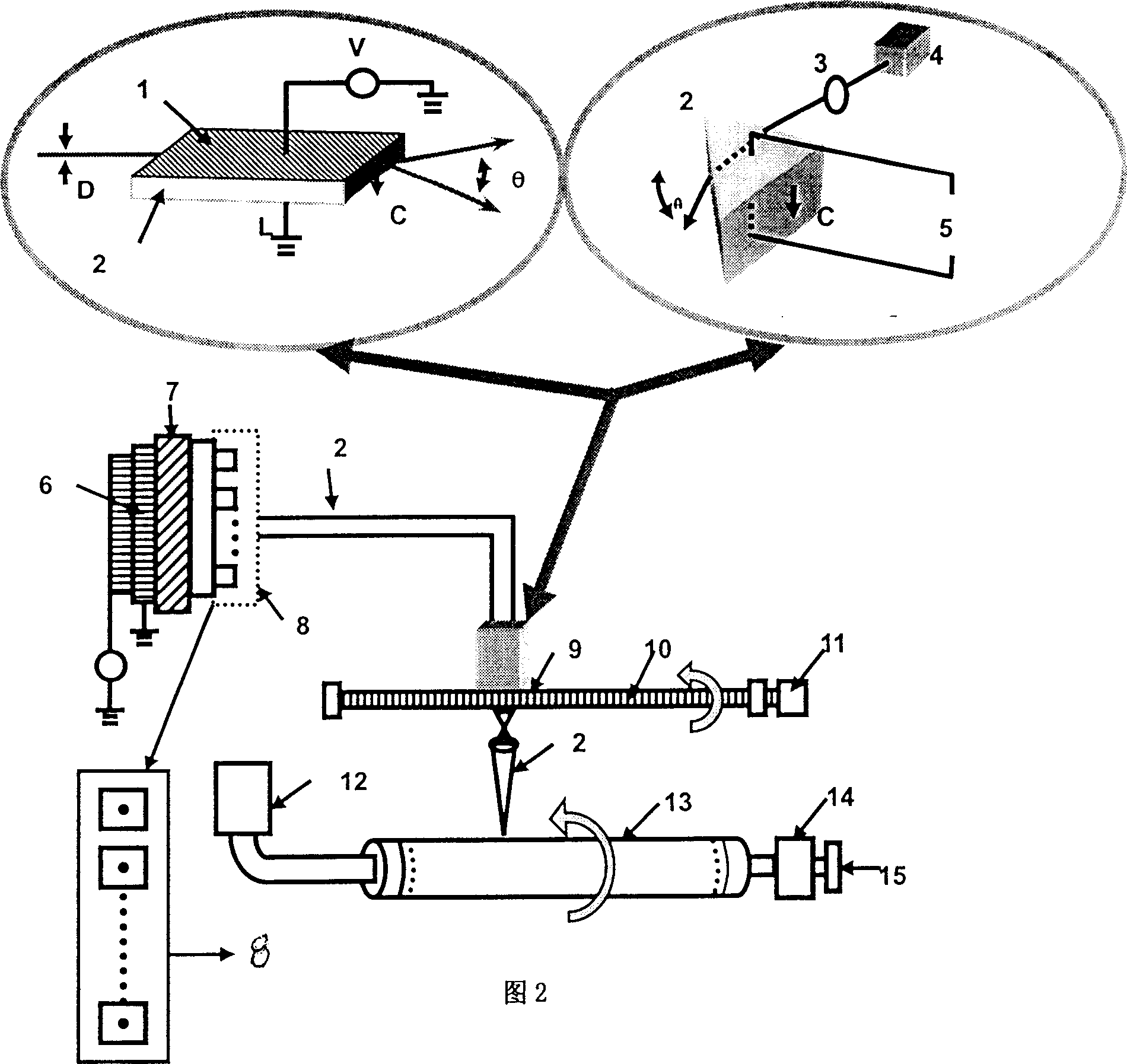

Embodiment 1

[0037] Implementation 1: Printed circuit board CTP plate making system, using laser solid-state micro-scanning technology to replace the current laser 4 array mechanical scanning; fixing the semiconductor device on the copper plate 7, and installing several silicon temperature control devices 6 through the back of the copper plate; and on the drum Long holes are punched in the middle of 23, and many small holes are punched on the surface; the laser thermal plate material is made by the method of heat-sensitive pigments, and the plate is made directly by a computer printer. The small holes on the surface of the drum achieve the function of constant temperature control and plate fixation;

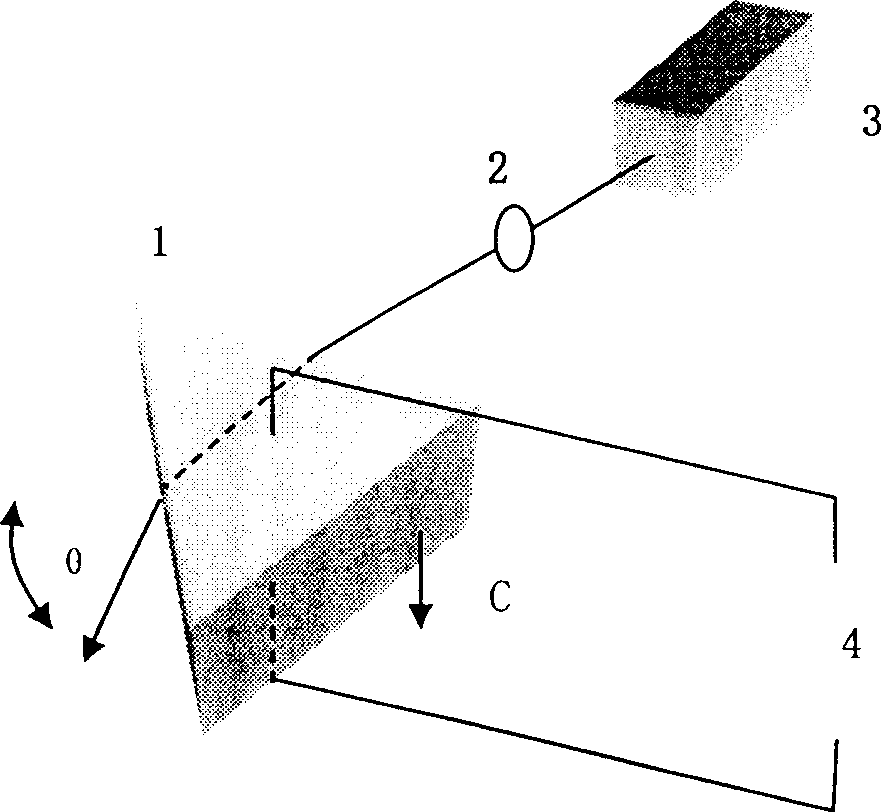

[0038] The laser solid-state micro-scanning technology actually uses such as image 3 , 4 The electrical optical deflector shown. When the laser 4 irradiates the electro-optical crystal 2 through the lens 3, it becomes incident light. The emitted light of the electro-optical crystal generates a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com