A liquid crystal photomask, its application and plate making device

A photomask and liquid crystal technology, which is used in photoplate-making process exposure devices, optics, nonlinear optics, etc., can solve the problems of large deviation between accuracy and design accuracy, easy to be affected by temperature, and difficult to debug line width. The effect of improving the accuracy of plate making and reducing the number of image transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

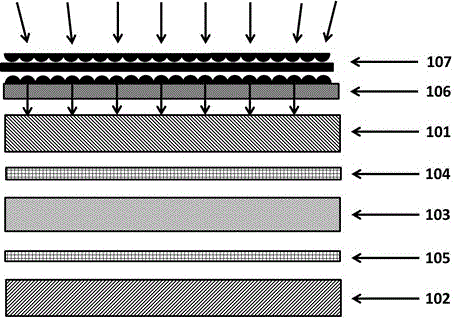

[0029] see figure 1 , the specific embodiment 1 provides a liquid crystal photomask, characterized in that the photomask includes an imaging controller (not shown), a light guide layer 106, a first optical deflector 101, a liquid crystal layer 103 and the second optical deflector 102; the liquid crystal layer 102 is sandwiched between the first optical deflector 101 and the second optical deflector 102; the liquid crystal layer 103 is a twisted nematic liquid crystal layer. A first transparent electrode layer 104 is provided on the surface of the first optical deflector 101 in contact with the liquid crystal layer 103 ; a second transparent conductive layer 105 is provided on the surface of the second optical deflector 102 in contact with the liquid crystal layer 103 .

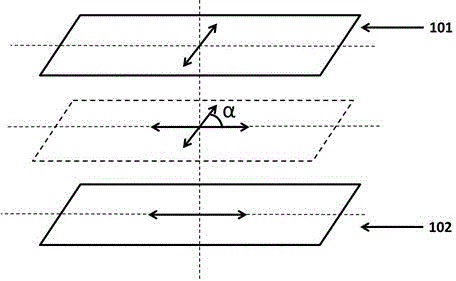

[0030] see figure 2 , the angle between the polarization direction of the first optical deflector 101 and the second optical deflector 102 is 90 degrees; the light guide layer 106 is arranged on the light in...

Embodiment 2

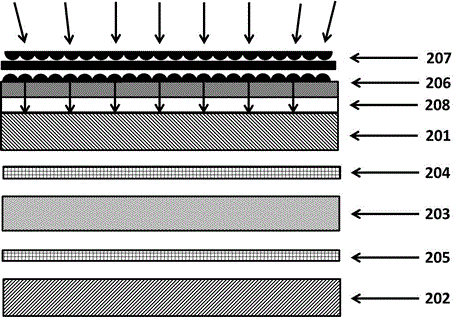

[0036] see image 3 , this specific embodiment 2 provides a kind of liquid crystal photomask, it is characterized in that, described photomask comprises, imaging controller, light guide layer 206, first optical deflection film 201, liquid crystal layer 203 and second optical deflection sheet 202; the liquid crystal layer 203 is sandwiched between the first optical deflection film 201 and the second optical deflection film 202; the liquid crystal layer 203 is a twisted nematic liquid crystal layer. A first transparent electrode layer 204 is arranged on the surface of the first optical deflector 201 in contact with the liquid crystal layer 203; a second transparent conductive layer 205 is arranged on the surface of the second optical deflector 202 in contact with the liquid crystal layer 203; The included angle between the polarization direction of the optical deflector 201 and the second optical deflector 202 is 90 degrees (same as in embodiment 1, not shown in the figure); si...

Embodiment 3

[0040] see Figure 4 , this specific embodiment 2 provides a kind of liquid crystal photomask, it is characterized in that, described photomask comprises, imaging controller, light guide, 206, first optical deflection film 301, liquid crystal layer 303 and second optical deflection sheet 302; the liquid crystal layer 303 is sandwiched between the first optical deflection film 301 and the second optical deflection film 302; the liquid crystal layer 303 is a twisted nematic liquid crystal layer. A first transparent electrode layer 304 is arranged on the surface of the first optical deflector 301 in contact with the liquid crystal layer 303; a second transparent conductive layer 305 is arranged on the surface of the second optical deflector 302 in contact with the liquid crystal layer 303; The angle between the polarization direction of the optical deflector 301 and the second optical deflector 302 is 90 degrees; the light guide layer 306 is arranged on the light incident side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com