Flexible printed circuit base material

A printed circuit and flexible technology, applied in the field of flexible printed circuit substrates, can solve the problems of reducing spacing, connection errors, inability to improve positioning accuracy, etc., to achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

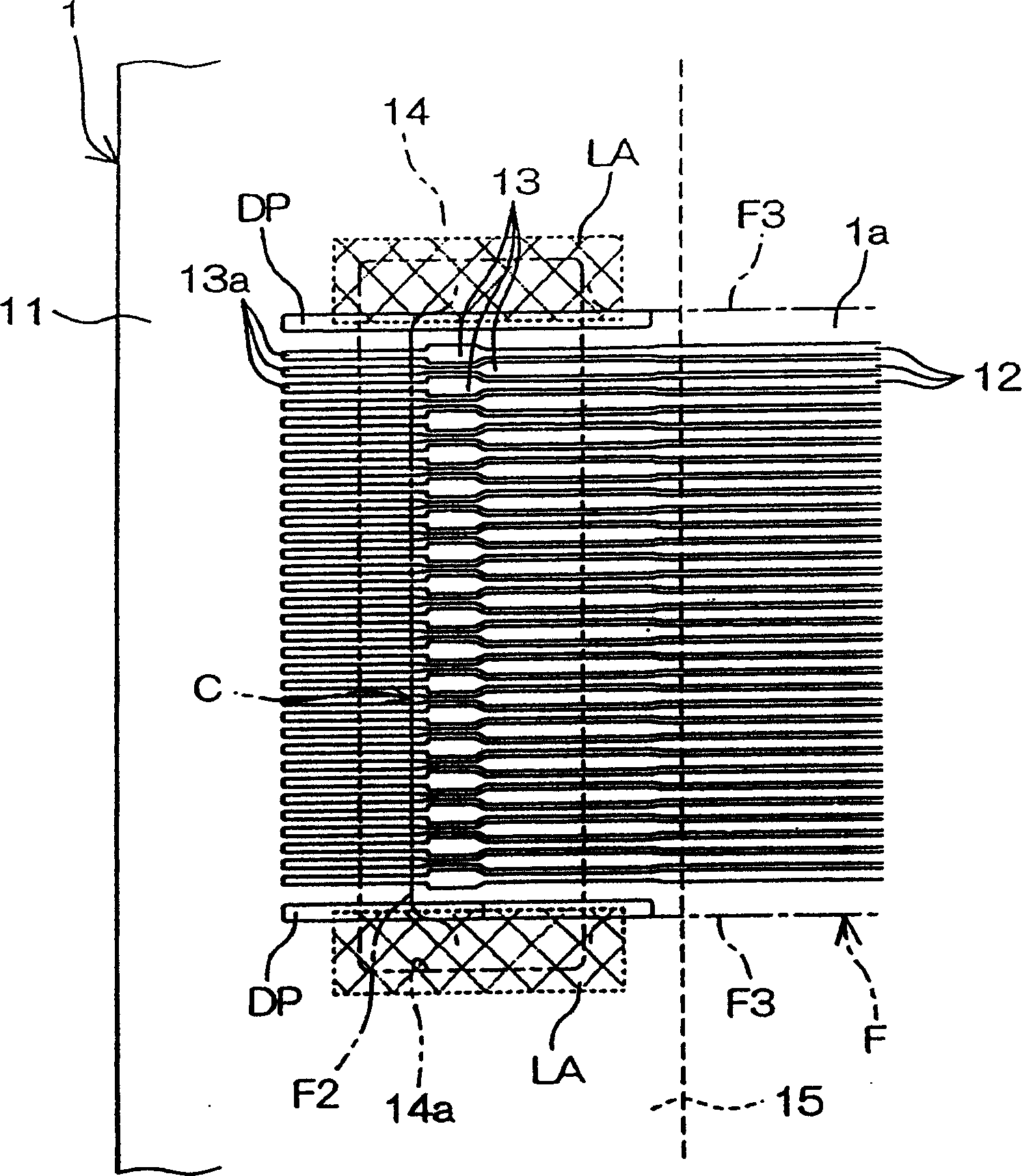

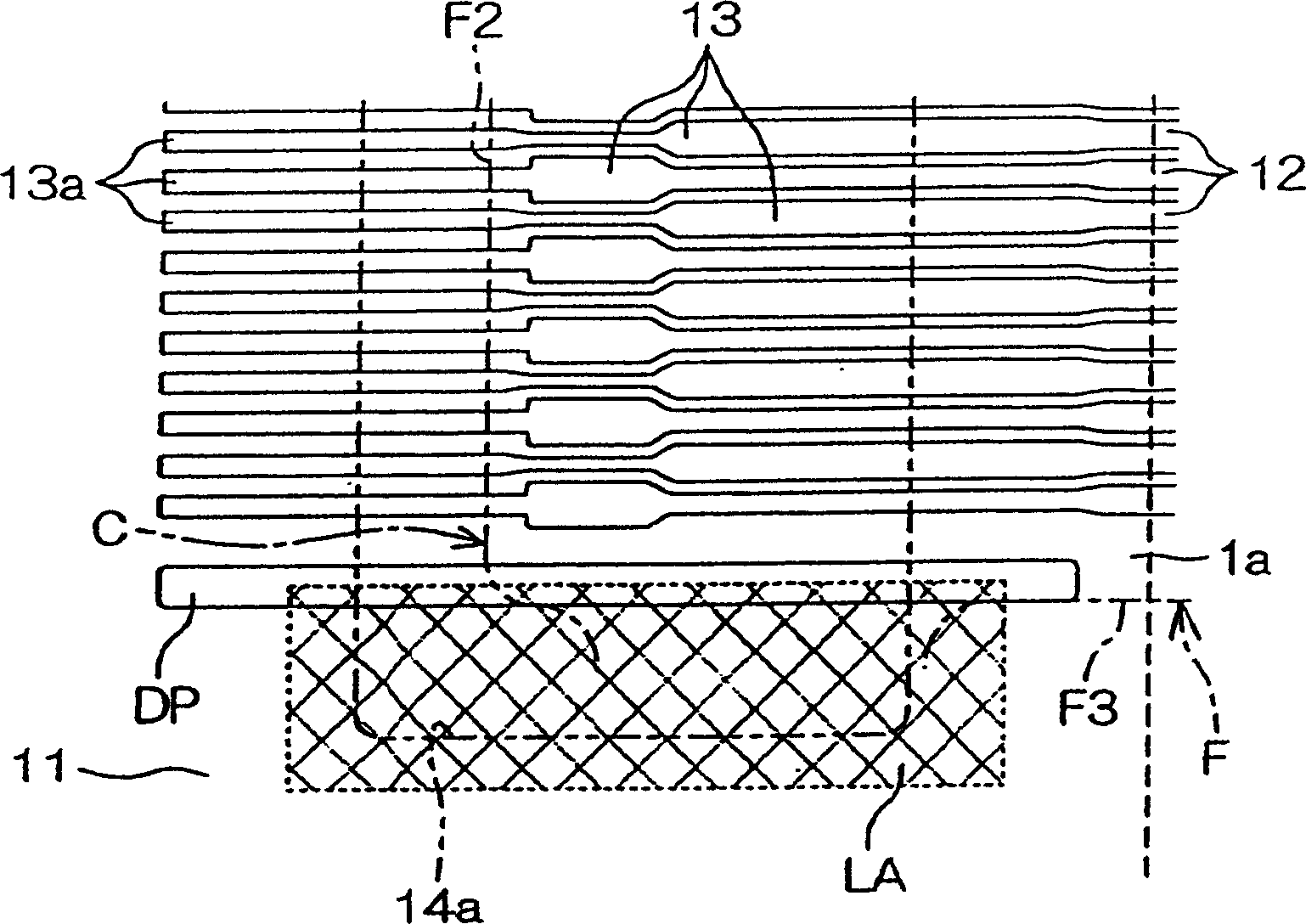

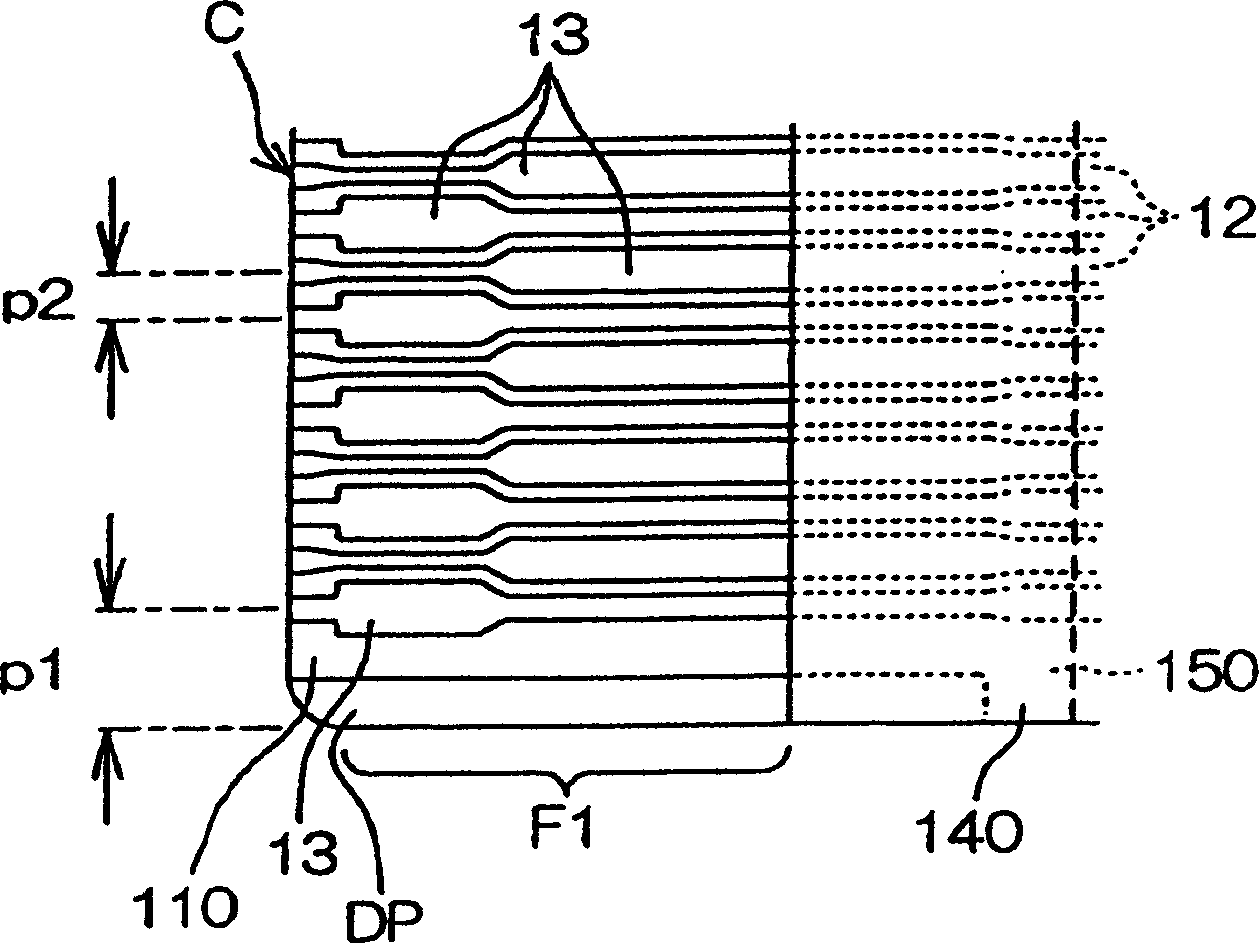

[0087] figure 1 It is an enlarged plan view of the area around the connection parts C of the flexible printed circuit board 1a in the flexible printed circuit substrate 1 according to an embodiment of the present invention. In addition, FIG. 2( a ) is an enlarged plan view of a surrounding area of the dummy pattern DP as a mask in the laser method for processing the base film 11 in the flexible printed circuit substrate 1 .

[0088] As shown in the above figure, by forming a region corresponding to the flexible printed circuit board 1a including the connection parts C on the surface of the base film 11 made of a flexible resin film or the like, the flexible printed circuit board 1a can be constructed. Circuit Substrate 1.

[0089] Although only one region corresponding to a single flexible printed circuit board is shown in the above figures, there are usually two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com