Method and device for separating materials

A technology of materials and mixed materials, applied in separation methods, liquid separation, precipitation separation, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

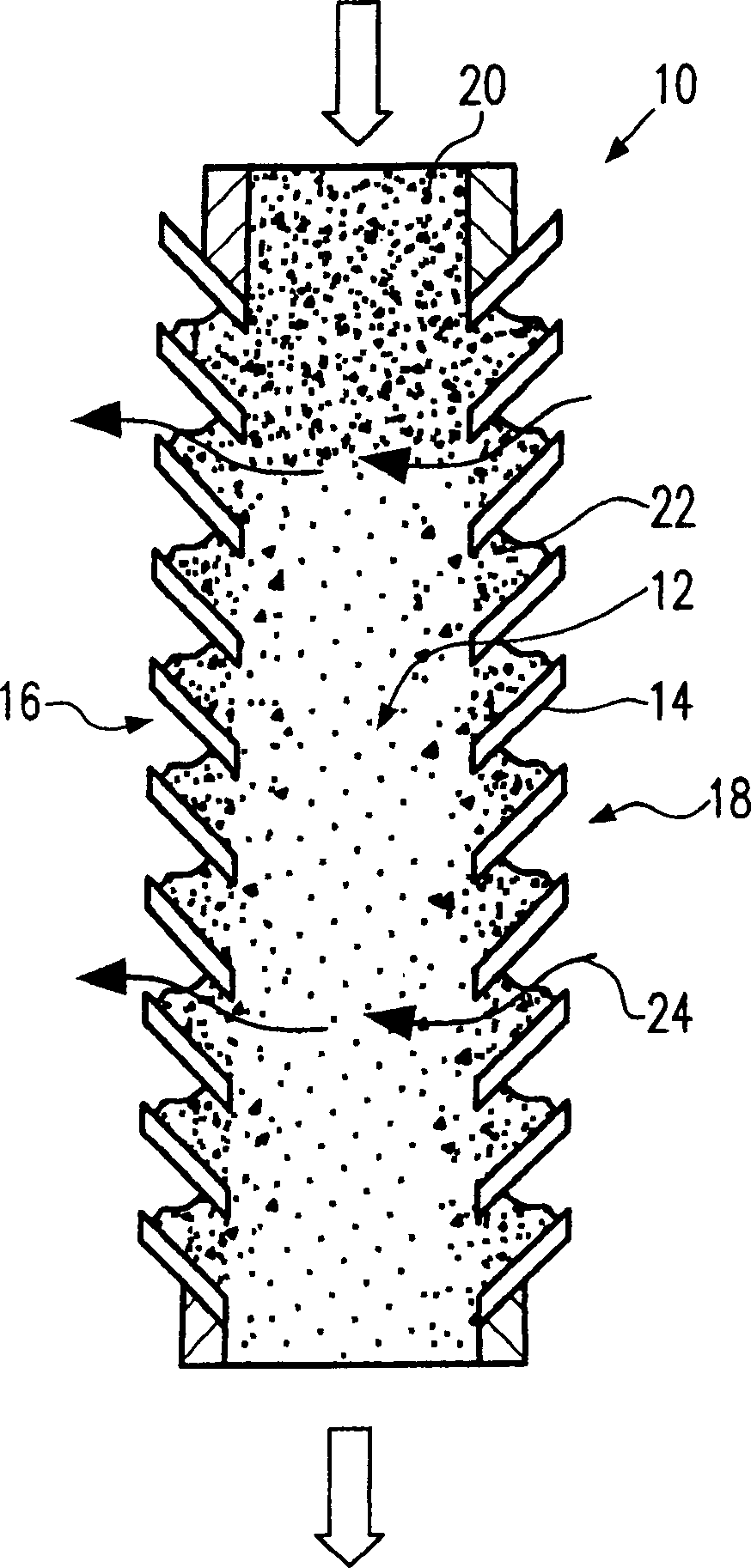

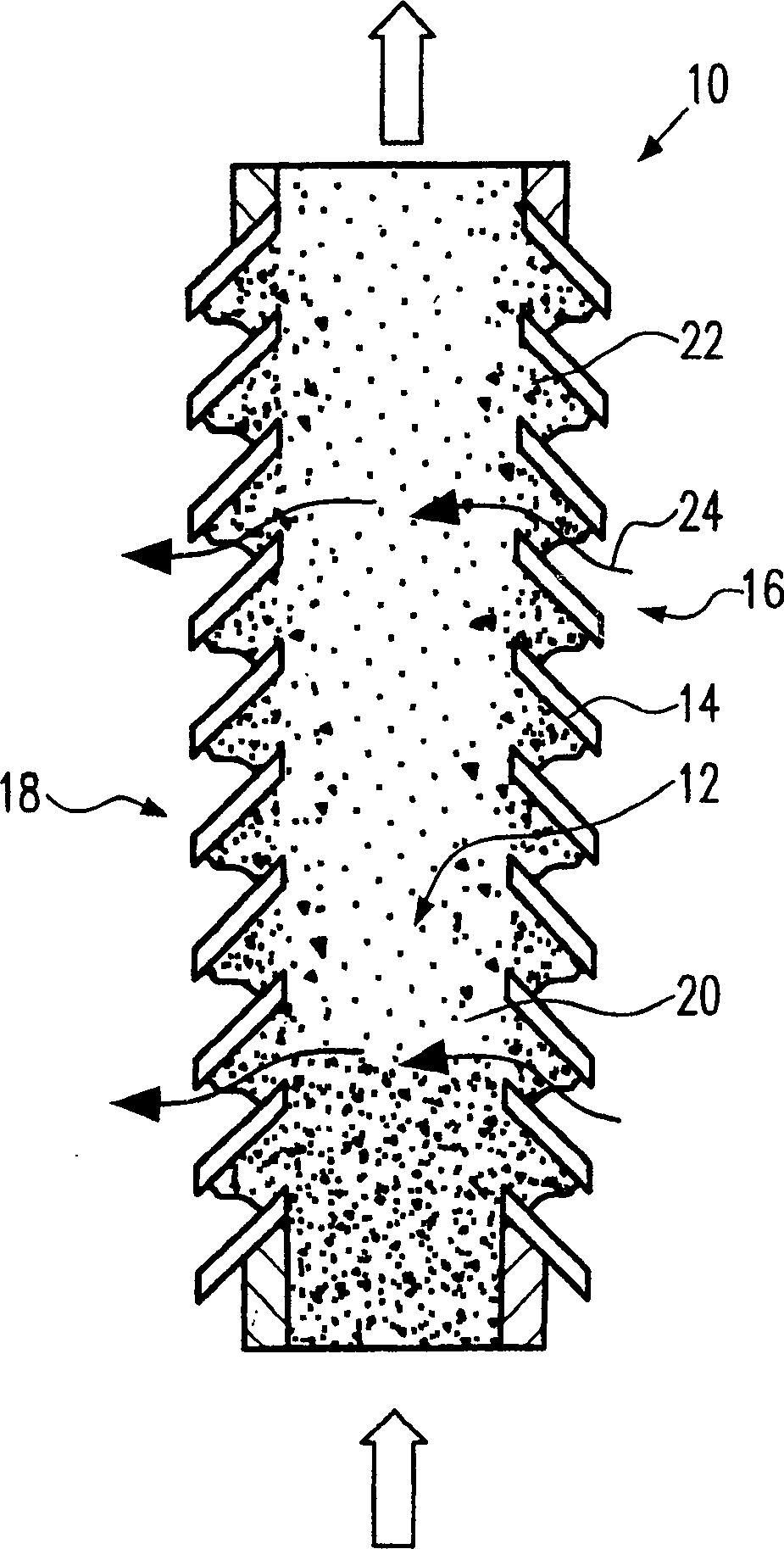

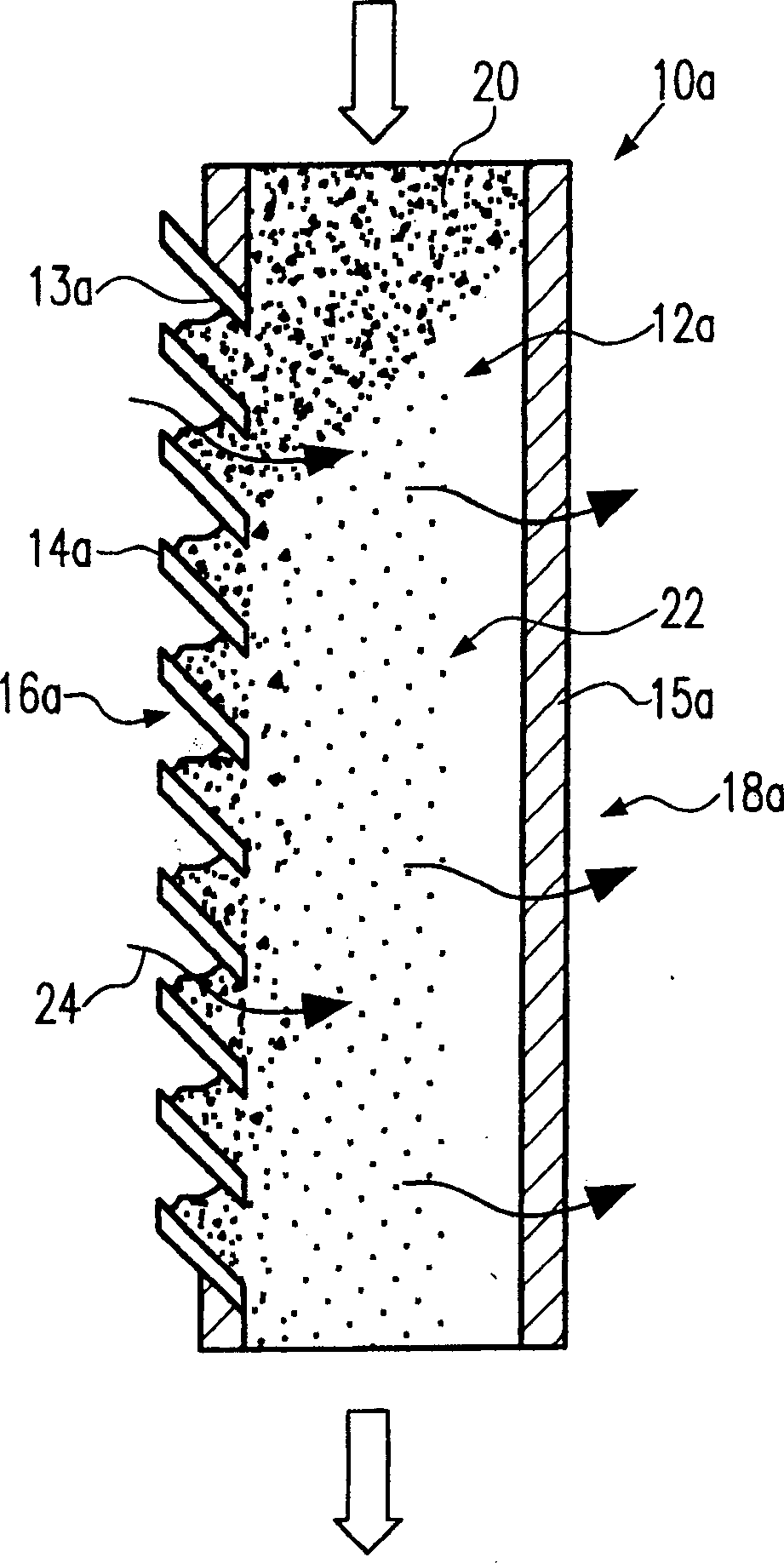

[0036] figure 1 is a schematic representation of a cross-sectional view of a device 10 for separating materials. The device 10 has a channel 12 extending in its longitudinal direction at least approximately parallel to the earth's gravitational field. In the illustrated embodiment, the channel 12 has a circular cross-section. A section of the channel 12 is formed by a plurality of circular guide members 14 which are arranged consecutively at equal intervals in the longitudinal direction of the channel 12 . The guide member 14 divides an unshown metal sheet into figure 1 The first part 16 shown on the left and figure 1 The second part 18 shown on the right is used for division.

[0037] The openings of the two parts 16 and 18 defined by the guide member 14 are connected to a not shown fluid channel for flushing fluid, and here the two fluid channels may for example be formed by a tube (not shown) arranged concentrically around the device 10 Formed, the device is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com