Plasma generation system

A plasma and generation system technology, applied in plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., can solve the problem that plasma cannot be formed uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

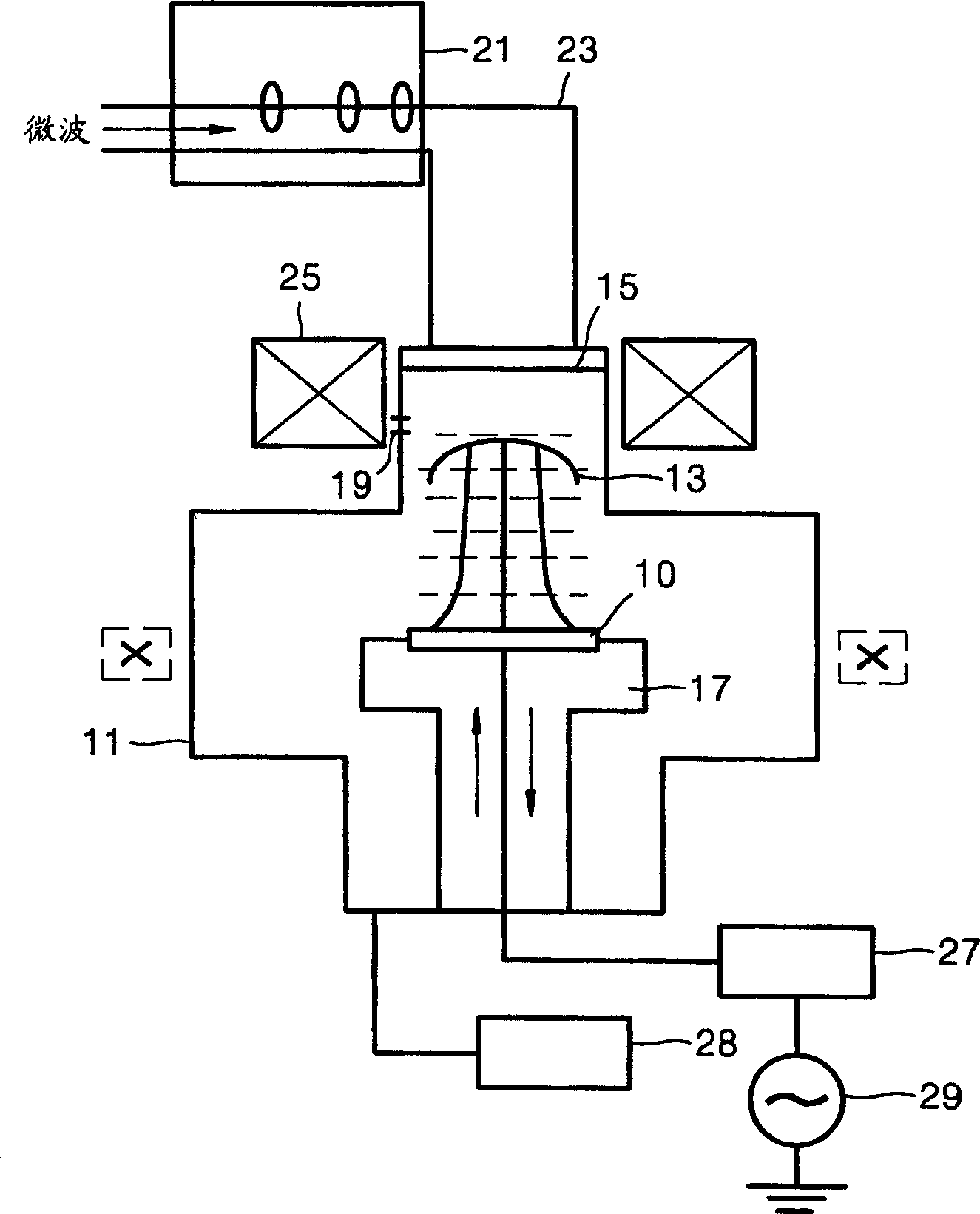

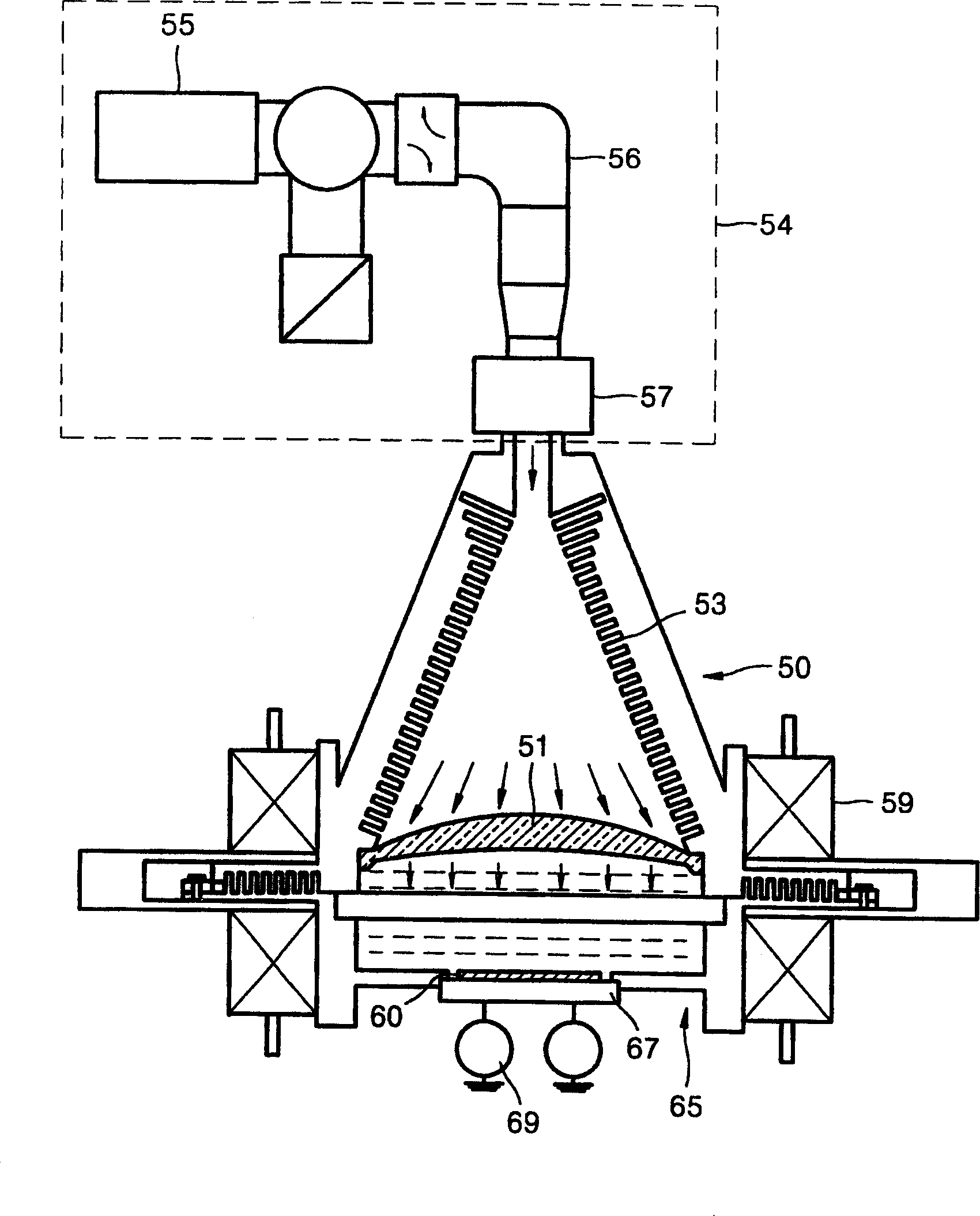

[0021] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0022] figure 2 The structure of the plasma generating system according to the embodiment of the present invention is schematically shown. refer to figure 2 A plasma generating system according to an embodiment of the present invention includes a microwave generator 54, a microwave conversion chamber 50 and a vacuum chamber 65 in which plasma etching is performed.

[0023] Microwave generator 54 comprises: a radio frequency energy source 55, is used to produce the ultra-high frequency microwave in the range of 300MHz to 1GHz; A waveguide 56, carries out microwave propagation through it; The microwaves are polarized in a single direction.

[0024] The microwave conversion chamber 50 is trumpet-shaped, and its width gradually increases in the direction of microwave propagation, so as to perform plasma etching on large-sized substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com