Plasma processing device with very-high frequency parallel resonance antenna

A plasma and processing equipment technology, applied in the field of plasma processing equipment, can solve problems such as inability to generate resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Detailed description of the preferred embodiment

[0025] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Regarding the reference numerals assigned to elements in the respective drawings, it should be noted that the same numerals as those assigned to elements in the conventional art represent elements performing the same functions, and thus their repeated descriptions are intentionally omitted.

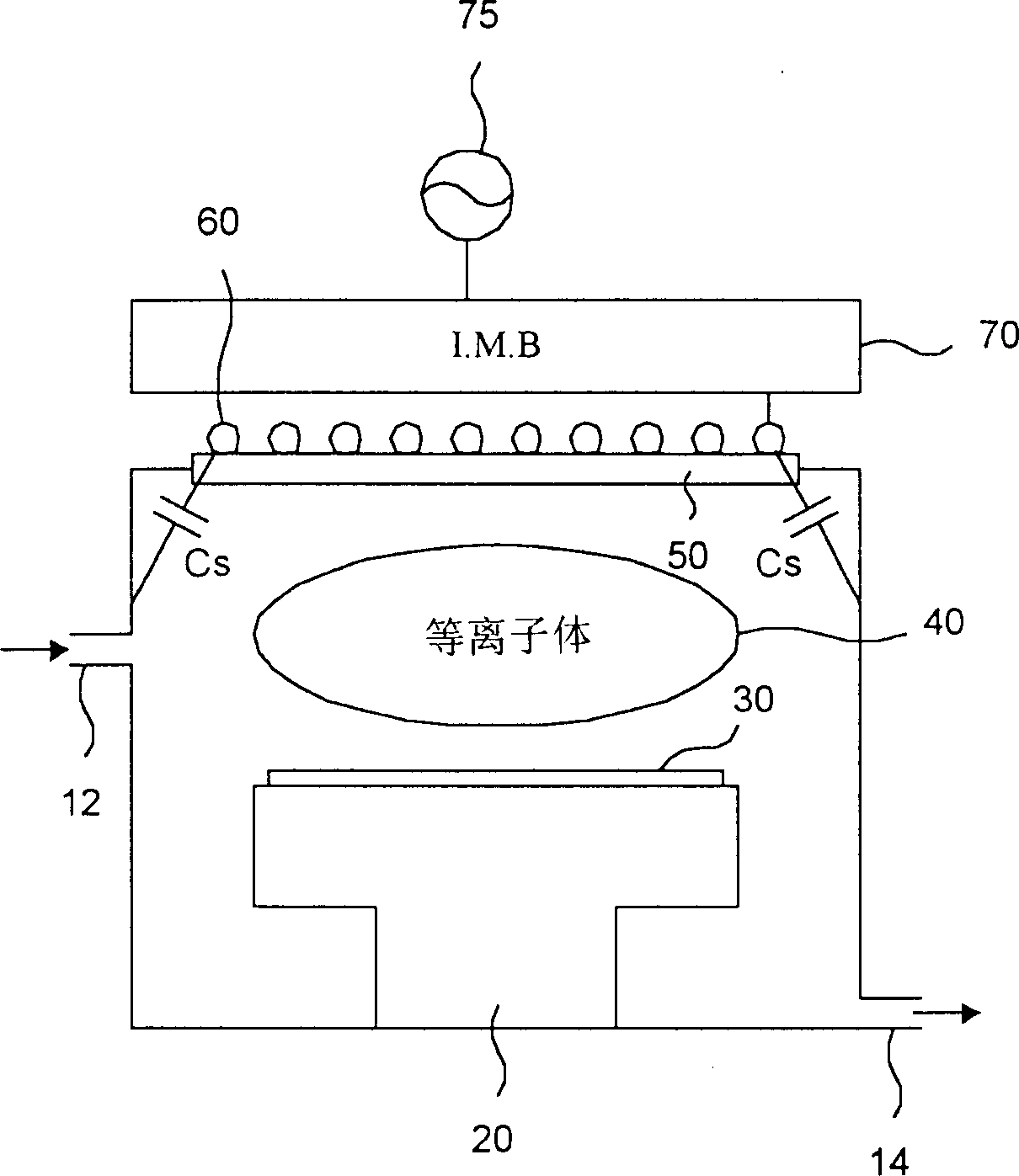

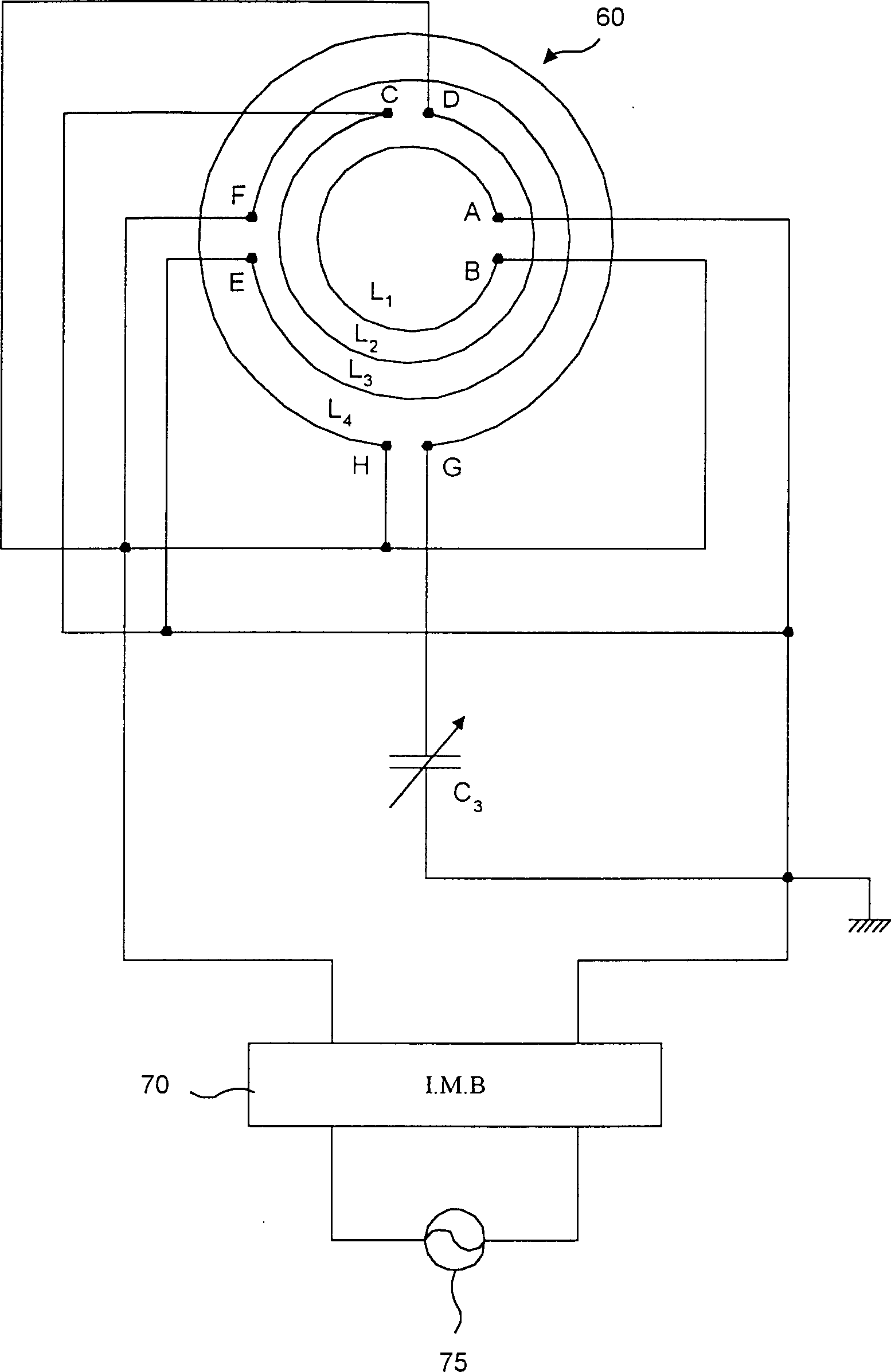

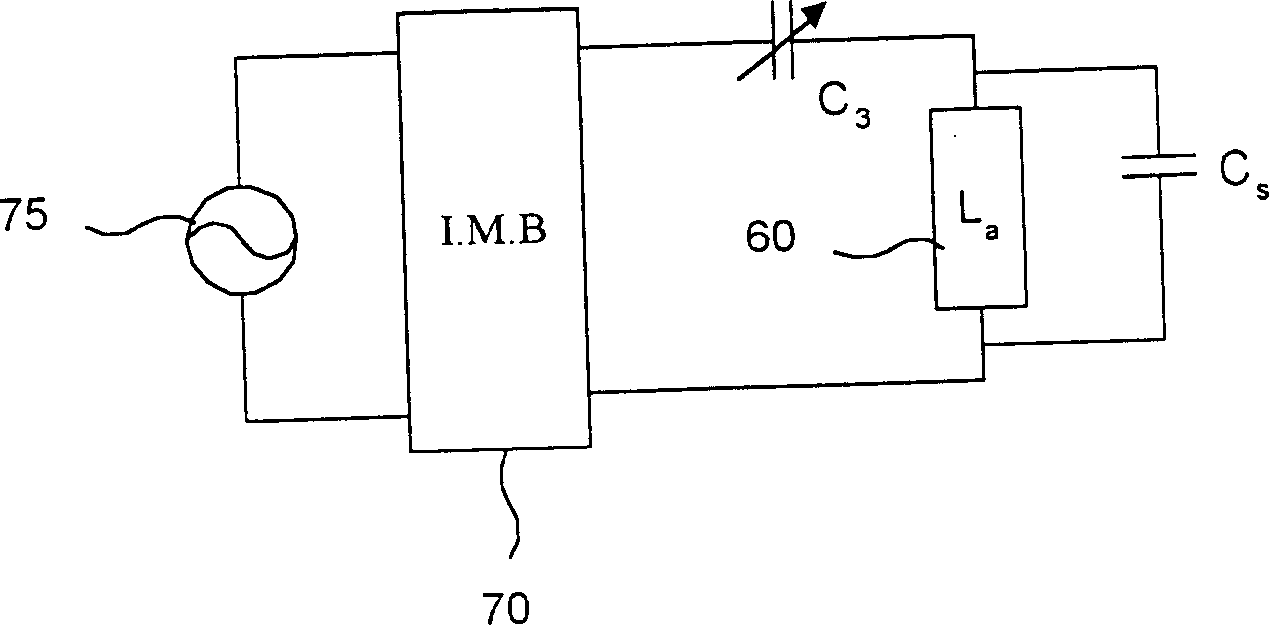

[0026] Figures 2a to 2c is a schematic diagram showing a VHF parallel resonant antenna according to the present invention. Specifically, Figure 2a with 2b is a schematic diagram showing the positional relationship between the very high frequency (VHF) parallel resonant antenna 60' and the impedance matching box 70, Figure 2c represents the equivalent circuit diagram, which includes the Figure 2a with 2b in the parasitic capacitance.

[0027] see Figures 2a to 2c , VHF parallel resonant anten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com