Prolonged discharge and thermal stabilized gear oil formula

A technology of gear oil and base oil, which is applied in the petroleum industry, specific vehicle lighting, lighting and heating equipment, etc. It can solve the problems that the processing rate cannot be provided, the lack of EP performance, and the phosphite cannot provide high-temperature wear protection and running-in performance. Achieve excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] The components of the gear oil blends of the present invention are included in Table 1.

[0075] sample

A

B

C

D

E

F

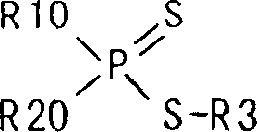

Phosphorodithioate

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

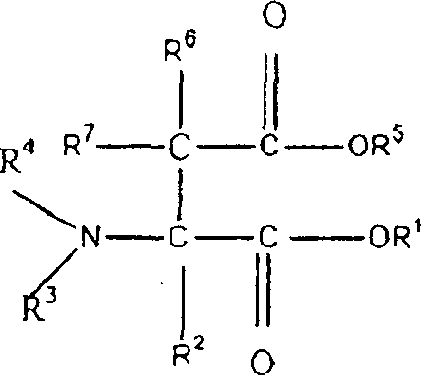

dialkyl phosphite

Y

acid phosphate

Y

Y

Y

Y

EP additive

SIBs

SIBs

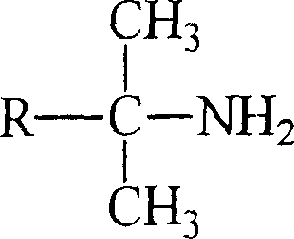

Di-tert-butyl

Trisulfide

compounds

Di-tert-butyl

Trisulfide

compounds

Sulfur activity of EP

55

55

126

4

126

4

metal cleaner

none

none

none

none

none

none

% sulfur from packaging

1.5

1.5

1.4

1.4

1.4

1.4

% phosphorus from packaging

0.13

0.19

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com