Trolley for construcing integral mould and building lining moulding board in loopful tunnel

A formwork trolley and integral formwork technology, which is used in tunnel lining, tunnel, shaft lining, etc., can solve the problem that the excavation operation cannot be carried out in parallel with the lining construction, the lining construction equipment cannot pass the transportation vehicle, and cannot meet the construction requirements of long railway tunnels. and other problems, to achieve the effect of shortening the construction period, reasonable structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

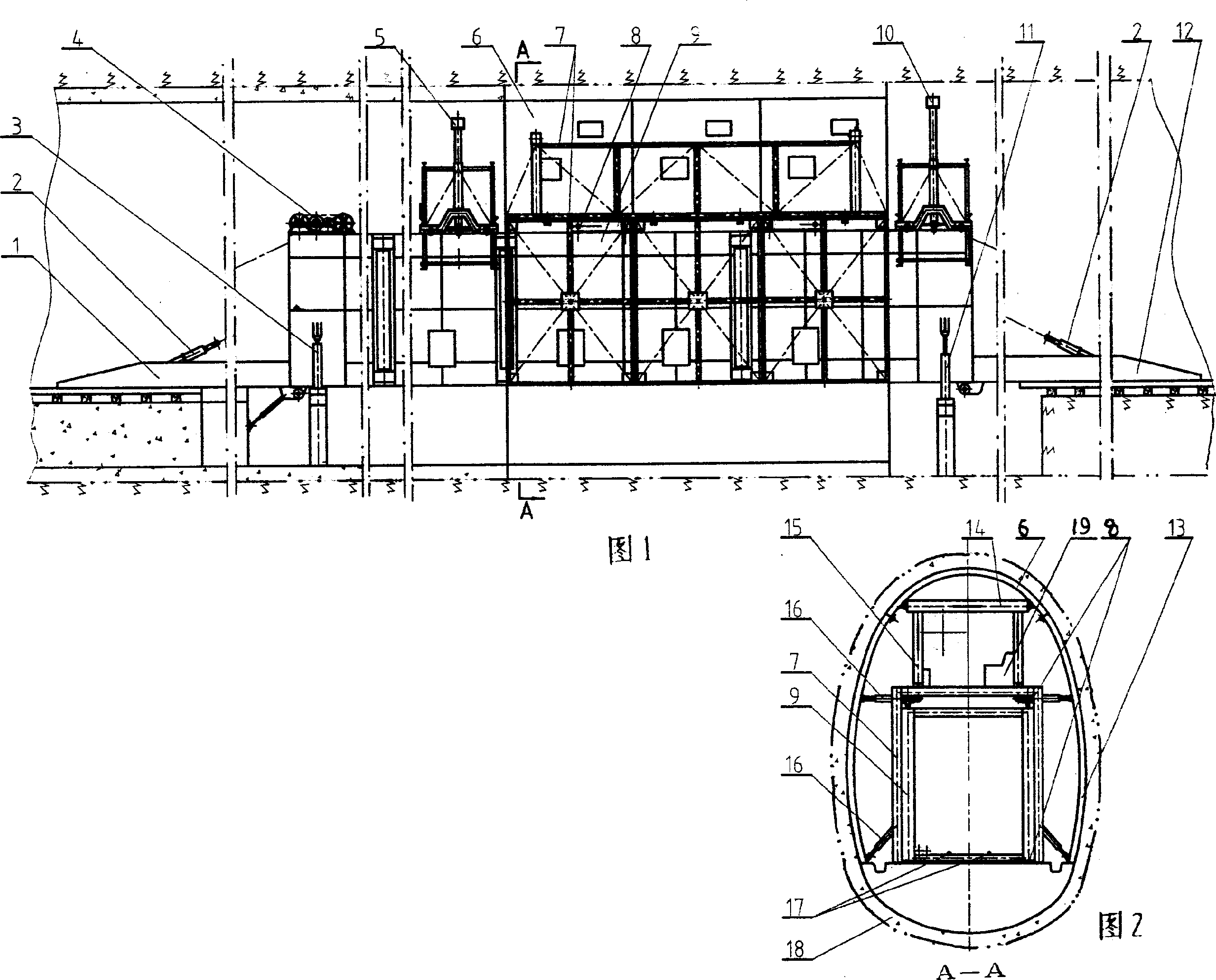

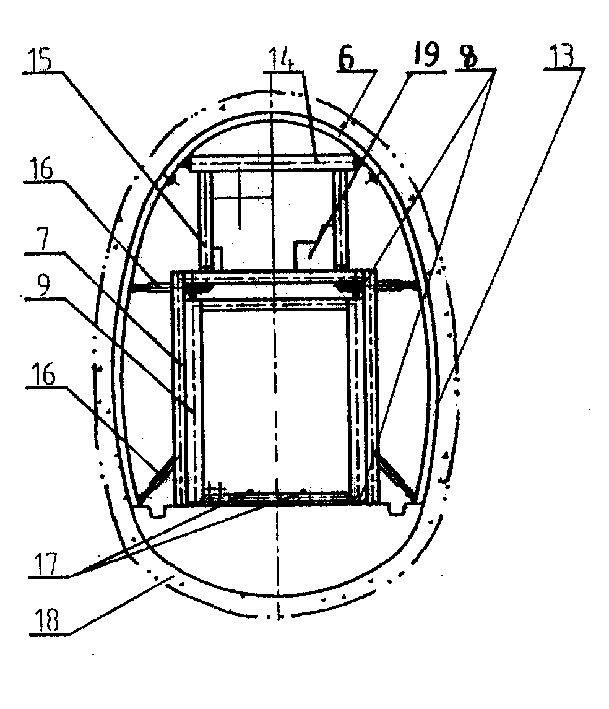

[0009] As shown in Figures 1 and 2, the structure of this tunnel full-loop integrally molded lining formwork trolley includes a frame beam with a retractable front support 3, a rear support 11, a front anti-floating platform 5, and a rear anti-floating platform 10 9. The frame 7 installed on the frame beam 9, the upper template cylinders 14, 15 installed on the frame 7, the side template cylinder 16 and the corresponding upper template 6 connected to each cylinder, the side template 13 and the frame The guide wheel guide rail structure 8 between the beam 9 and the frame 7, the structural relationship among the above-mentioned components, the bottom mold 18, the winch 4 that makes the frame and the frame beam alternately move, the pump station 19 and other components can all follow the existing structure. Technical composition. The upper template oil cylinder can be used together with a widening telescopic oil cylinder 14 and a jacking oil cylinder 15 to facilitate the lining to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com