Directly cooling refrigerator and its mounting method

An installation method and refrigerator technology, which are used in household refrigerators, refrigeration and liquefaction, household refrigeration devices, etc., can solve the problems of refrigerant blockage pressure, uneven expansion, and drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

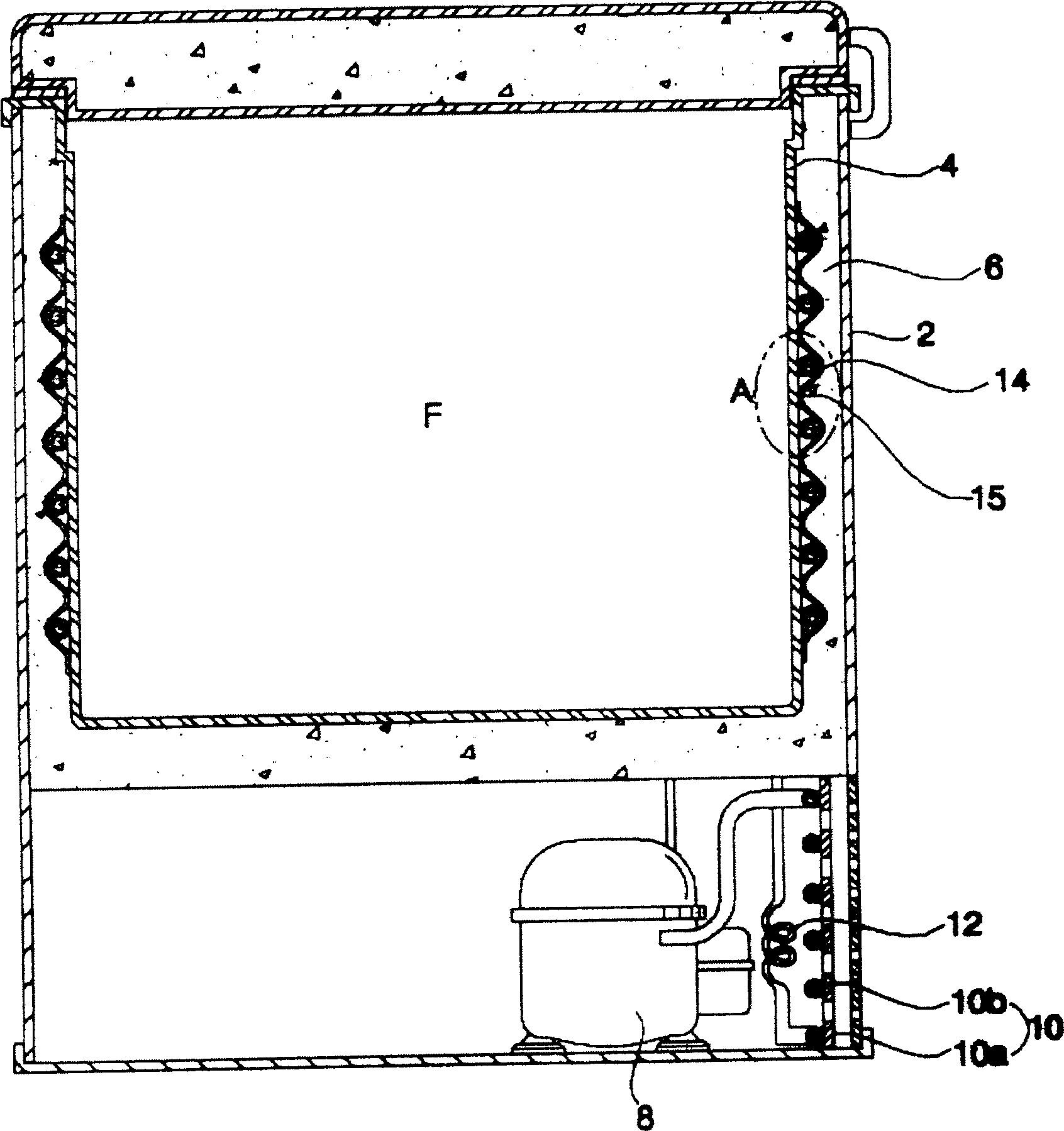

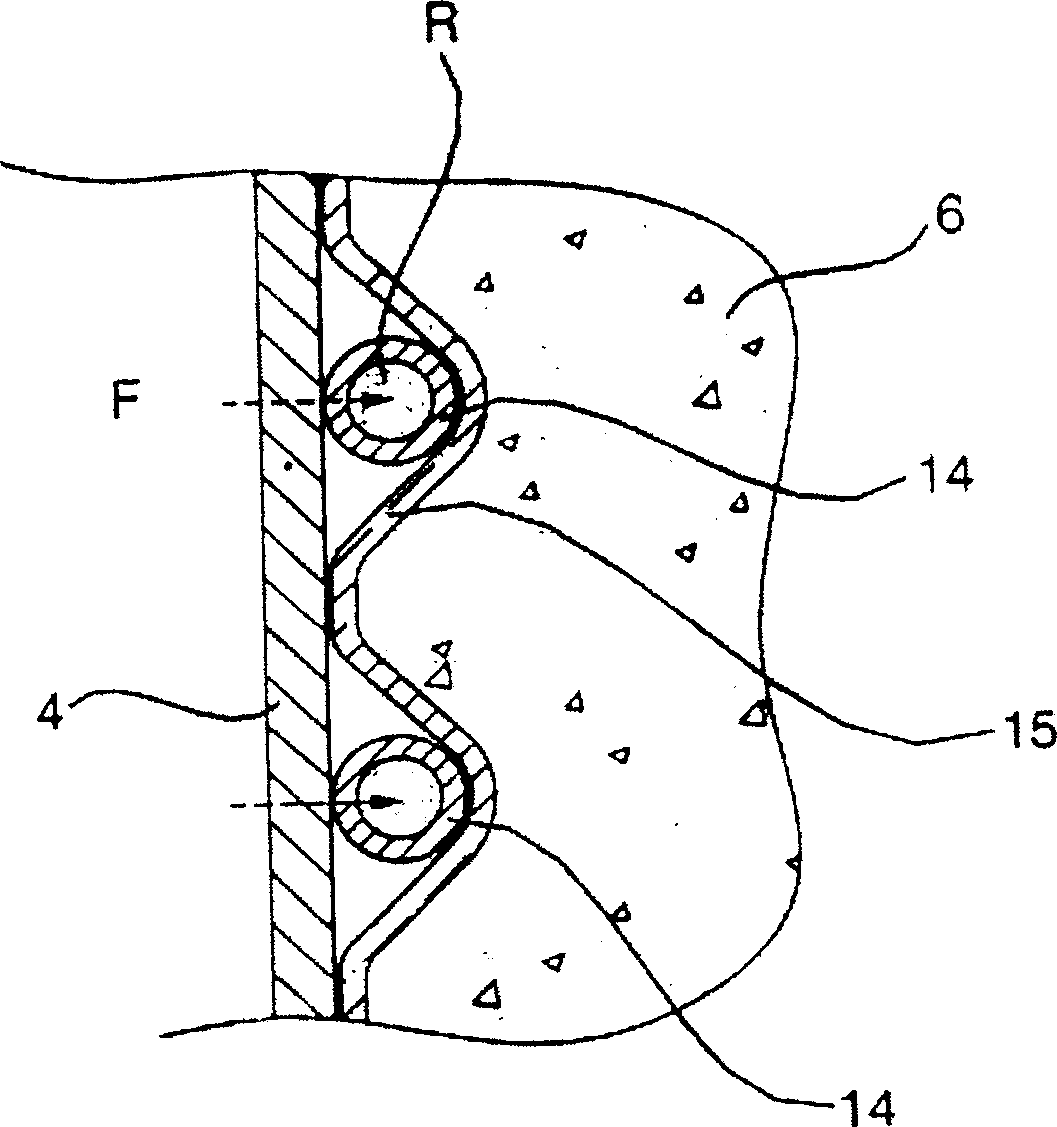

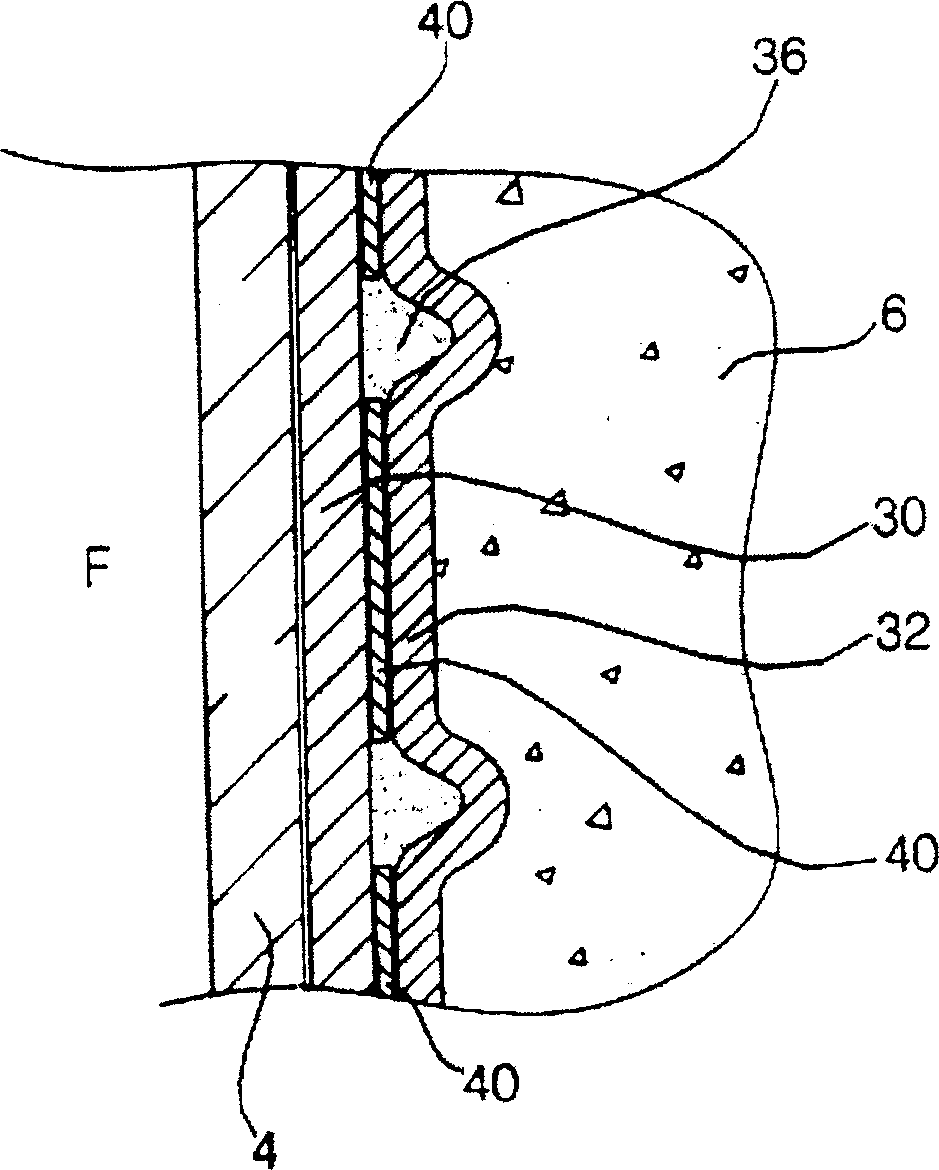

[0035] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0036] Such as Figure 4 As shown in FIG. 5 , the direct cooling refrigerator according to the first embodiment of the present invention includes an outer casing 52 forming the outer shape of the refrigerator; an inner casing 54 forming a storage room F arranged inside the outer casing 52; A compressor 56 for compressing refrigerant; a condenser 58 for condensing high-pressure refrigerant gas passing through the compressor 56 into a liquid state; an expansion mechanism 61 for decompressing the refrigerant passing through the aforementioned condenser 58; 61 an evaporator 62 that cools the inner case 54 by exchanging heat with the inner case 54 while the passing refrigerant is evaporated; an insulating material 64 filled between the outer case 52 and the inner case 54; A temperature sensor 66 for sensing the temperature of the internal housing 54 ; and a control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com