An active gas generating method and apparatus thereof

A technology of active gas and generating device, applied in water supply device, electrical components, plasma, etc., can solve the problem that the surface is easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

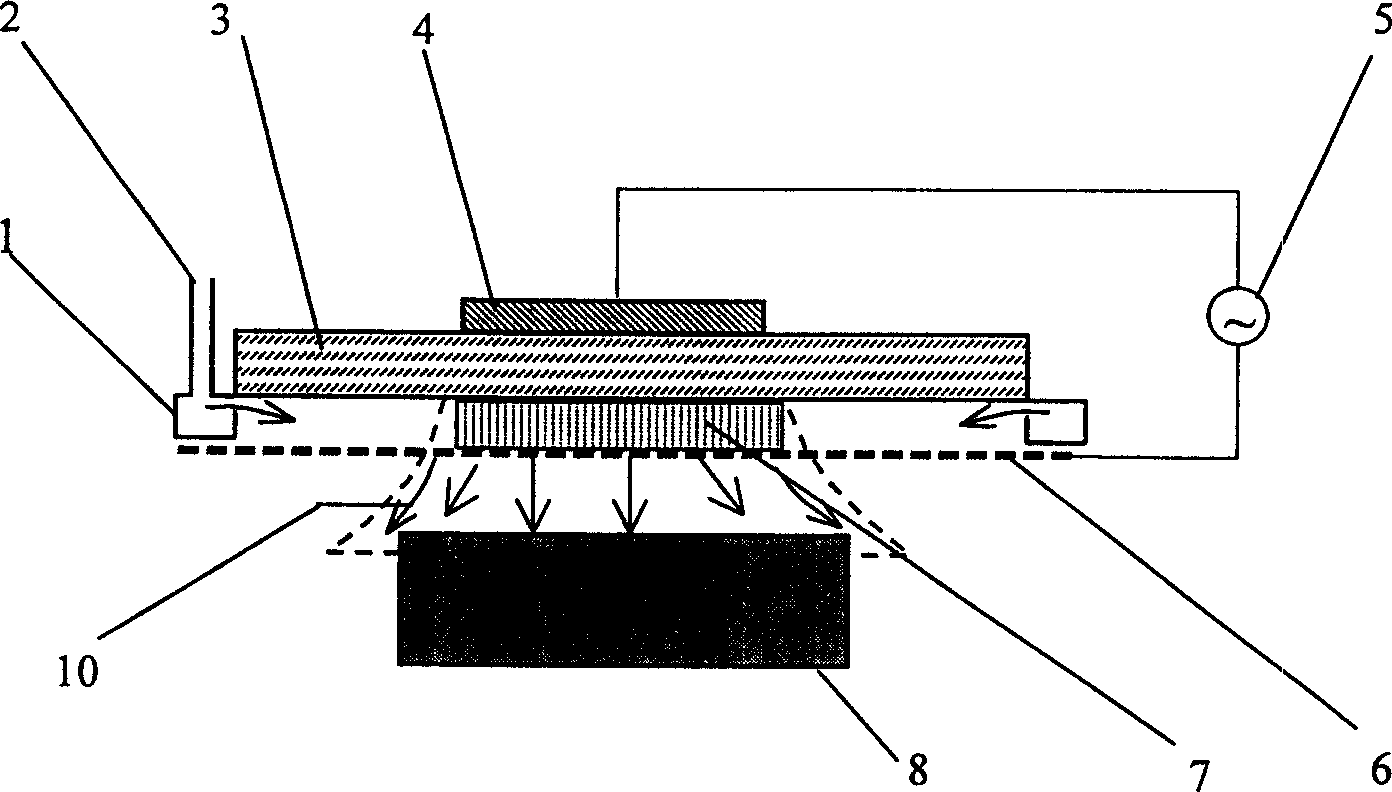

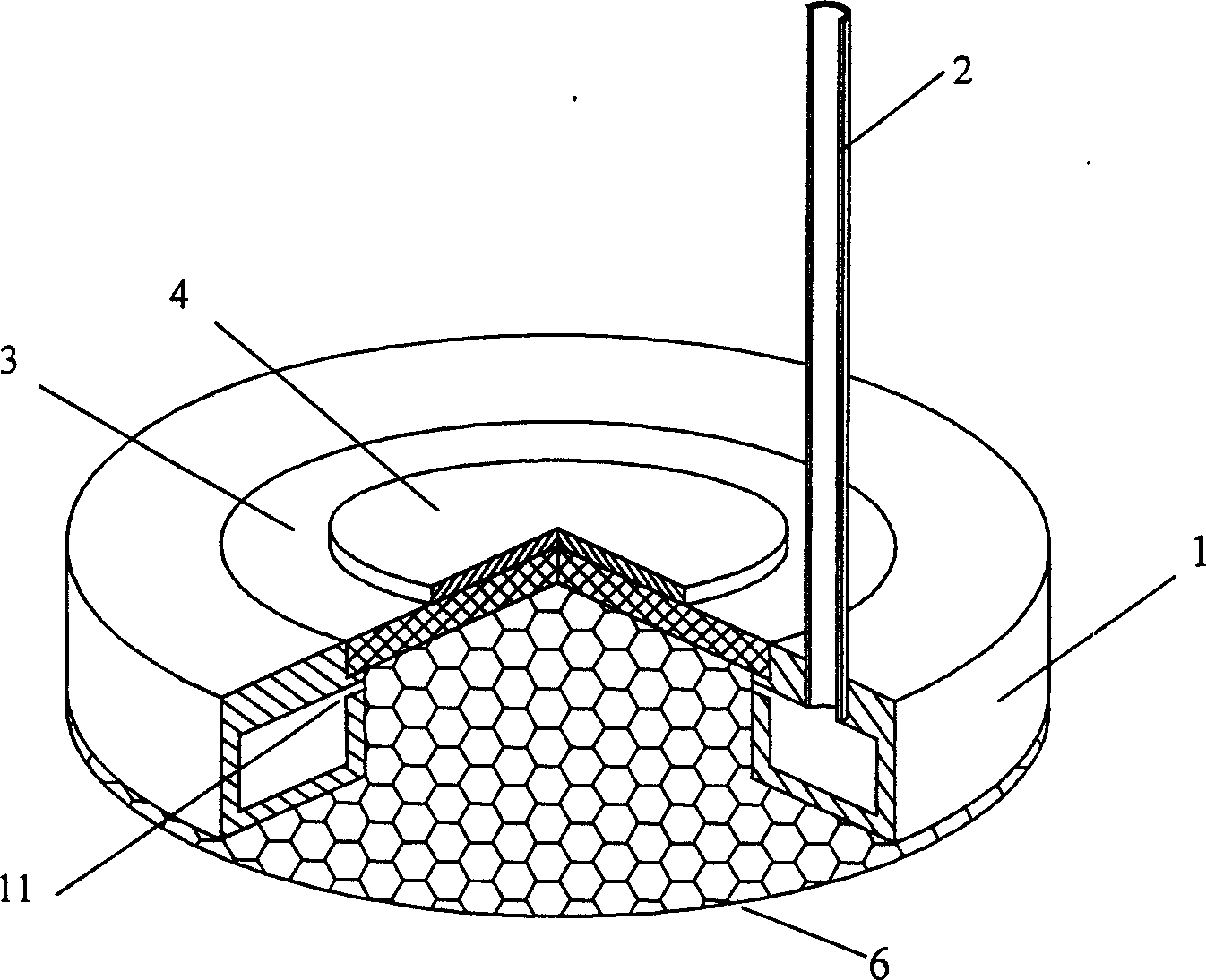

[0034] figure 1 Shown is a space discharge active gas generating device, including an alternating power supply 5 with an effective voltage of 8KV and a frequency of 30KHz. Its waveform can be sinusoidal, rectangular or other pulse waveforms, and its voltage is required to be between positive and negative Periodic changes. An output end of the alternating current power supply 5 is connected to the annular sheet-shaped upper electrode 4, and the lower surface of the upper electrode 4 is covered with an insulating dielectric sheet 3 with a thickness of 3 mm. The mesh lower electrode 6 is connected to the other output end of the alternating current power supply 5, and is placed under the insulating dielectric sheet 3 in parallel, with a distance of 5 mm from the insulating dielectric sheet 3. The mesh lower electrode 6 has mesh holes; discharge Zone 7 is between mesh electrode 6 and insulating dielectric sheet 3 . An annular gas supply channel 1 surrounds the discharge area 7 . ...

Embodiment 2

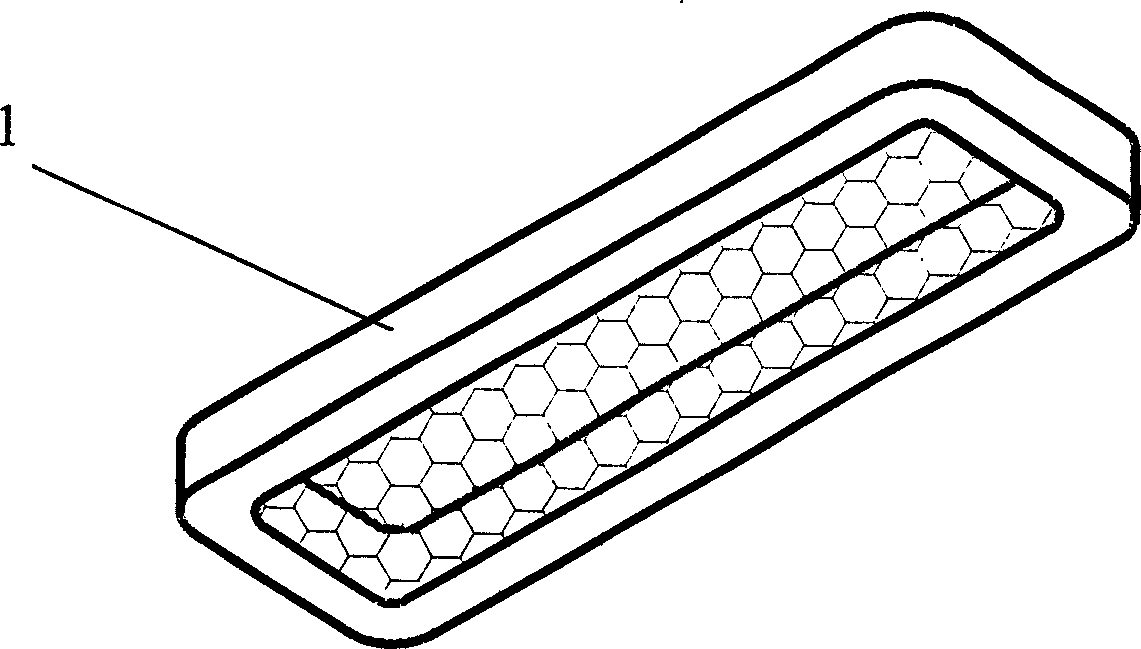

[0037] An active gas generating device in this embodiment is similar to that in Embodiment 1, and both adopt the space discharge type. The difference is that the air supply channel 1 is a rectangular closed air supply channel, such as image 3 shown. Figure 4 It is a cross-sectional view of the rectangular closed air supply channel in this embodiment.

Embodiment 3

[0039] Figure 5 It is an active gas generating device adopting surface discharge type or creeping discharge, which is similar to the device in Example 1. The difference is that the lower electrode 6 is a strip electrode. The strip-shaped bottom electrode 6 is in contact with the lower surface of the insulating dielectric sheet 3 , and the discharge area 7 is located around the strip-shaped bottom electrode 6 .

[0040] Surface discharge type electrodes can also be arranged in other ways, such as Figure 6 and Figure 7 shown. exist Figure 6 Among them, the upper electrode 4 is a sheet electrode, the lower electrode 6 is a block electrode, and the lower electrode 6 is in contact with the side of the insulating dielectric sheet. exist Figure 7 Among them, the strip-shaped lower electrode 6 and the strip-shaped upper electrode 4 adopt a coplanar structure, that is, the upper and lower electrodes are located on the same surface of the medium, and the upper and lower elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com