Anchor recovering technology and anchor cable recovering technology in civil engineering

A technology for civil engineering and cable recovery, which is applied in infrastructure engineering, construction, sheet pile walls, etc. It can solve problems such as difficulty in pulling cables, inability to pull out recovery cables, and recovery costs, etc., and achieves low requirements for operating skills and facilitates construction , the effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

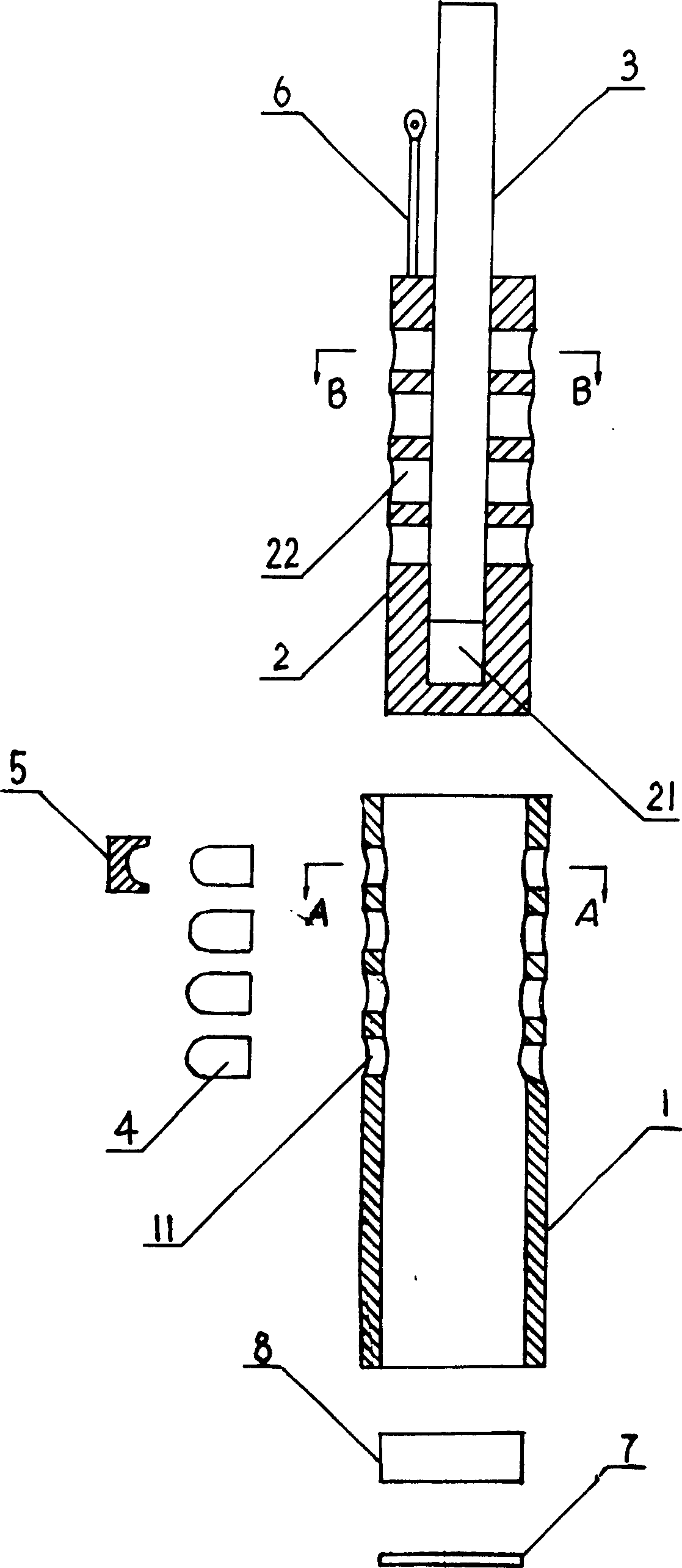

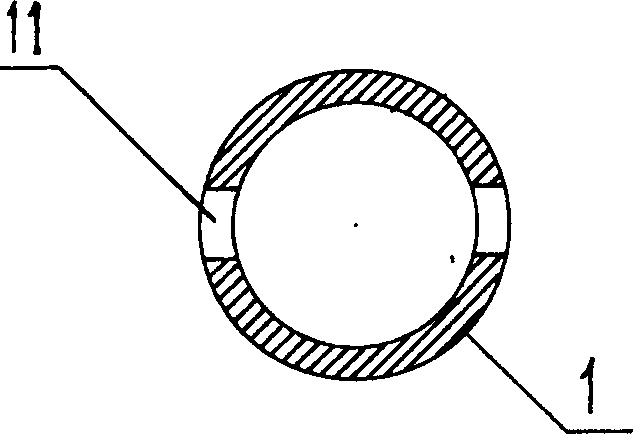

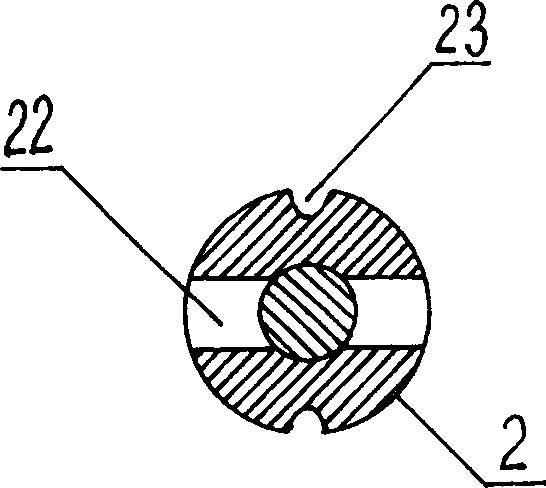

[0034] Such as Figure 1 to Figure 4 As shown in , a recovery anchor in civil engineering of the present invention is a two-cable recovery anchor, including an outer cylinder 1, a middle cylinder 2, an inner rod 3, a horizontal pin 4, a pin cap 5, a pull rod 6, and a sealing plate 7 And the positioning block 8, the outer cylinder 1 is a seamless steel pipe with a length of 450mm, a diameter of 83mm, and a wall thickness of 10mm, and two rows of four evenly distributed radial through holes are arranged on the wall of the outer cylinder 1 11; the middle tube 2 is a cylinder with a diameter of 61 mm and a length greater than the upper and lower positions of the through hole 11; a long hole 21 with a diameter of 20 mm and one-sided penetration is arranged axially in the middle of the middle tube 2, and the depth of the long hole 21 is greater than The upper and lower positions of the through holes 11; the middle cylinder 2 is provided with radial holes 22 corresponding to the eigh...

Embodiment 2

[0036] Such as Figure 5 to Figure 8As shown in , a recovery anchor in civil engineering of the present invention is a four-cable recovery anchor, including an outer cylinder 1, a middle cylinder 2, an inner rod 3, a horizontal pin 4, a pin cap 5, a pull rod 6, and a sealing plate 7 and the positioning block 8, the outer cylinder 1 is a seamless steel pipe with a length of 450mm, a diameter of 95mm, and a wall thickness of 10mm, and four rows of radial through holes are arranged on the wall of the outer cylinder 1 and each row is uniformly distributed. 11; the middle tube 2 is a metal cylinder with a diameter of 74mm and a length greater than the upper and lower positions of the through hole 11; the middle part of the middle tube 2 is provided with a single-sided long hole 21 with a diameter of 28mm in the axial direction, and the depth of the long hole 21 is greater than The upper and lower positions of the through holes 11; the middle cylinder 2 is provided with a radial hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com