Point-divided full-voltage generation technology adapted to large range changes of rotating speed

A large-scale and technical technology, applied in the field of split-point full-voltage power generation technology, can solve the problem of providing guaranteed voltage for the power system, and achieve the effect of improving the voltage utilization rate and meeting the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Divide the coil elements in the stator windings of each phase in the generator into four parts that are physically and electrically identical in structure, and each part leads to a set of independent terminals. An array of electronically controlled switches is connected between the terminals of each adjacent two parts. Through the different on and off changes of the switches in the switch array, different series and parallel connections can be realized between the coil elements of the four parts, and the same name can be achieved. The direction of the current at the terminals remains the same.

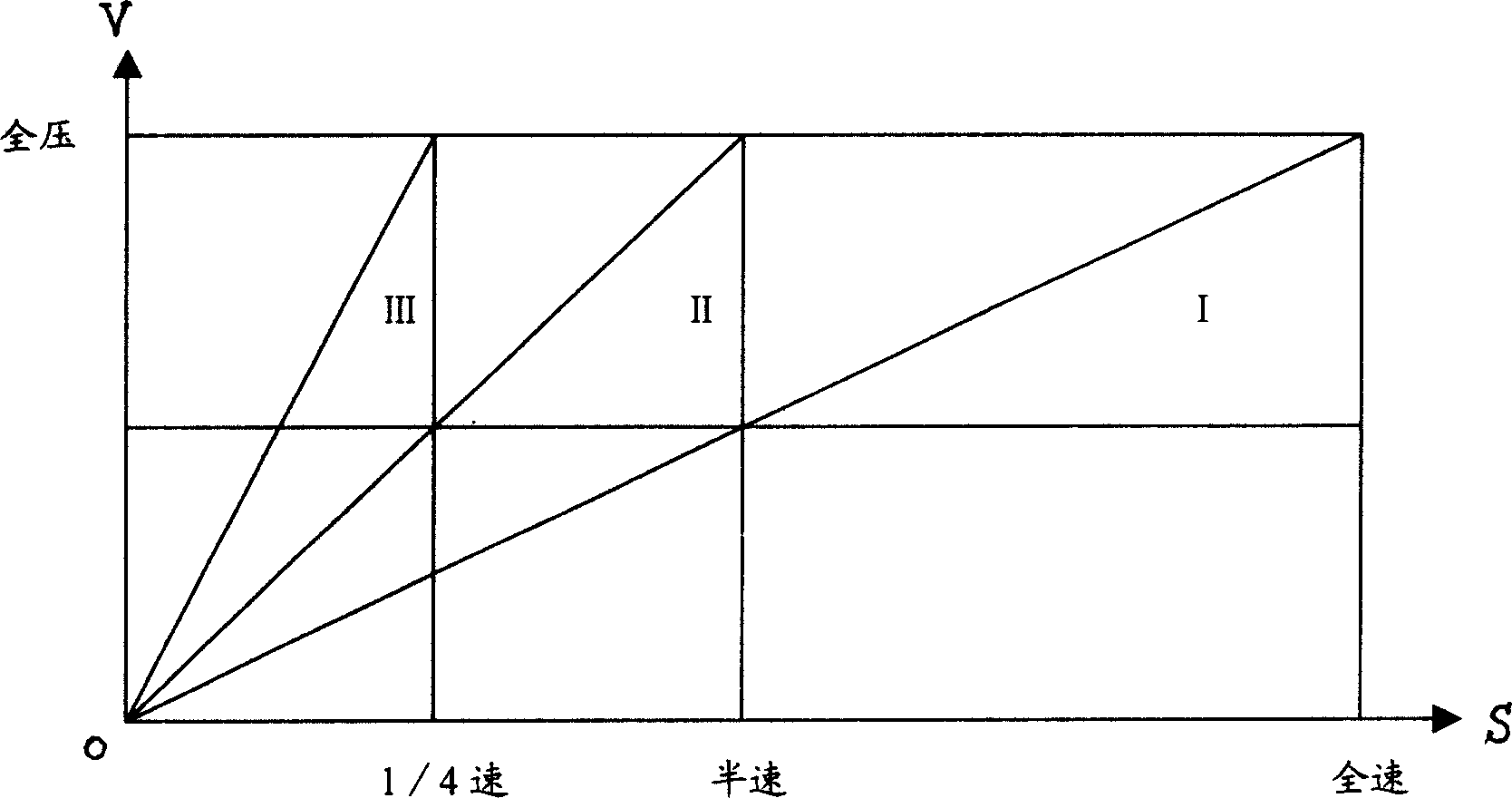

[0015] When the generator is running at full speed, the four parts of the coil elements in the stator winding of each phase are connected in parallel, and the output is full voltage at this time. When the speed is reduced by half, the four parts of the coil elements are controlled by the on-off change of the electronically controlled switch array, and are connected...

Embodiment 2

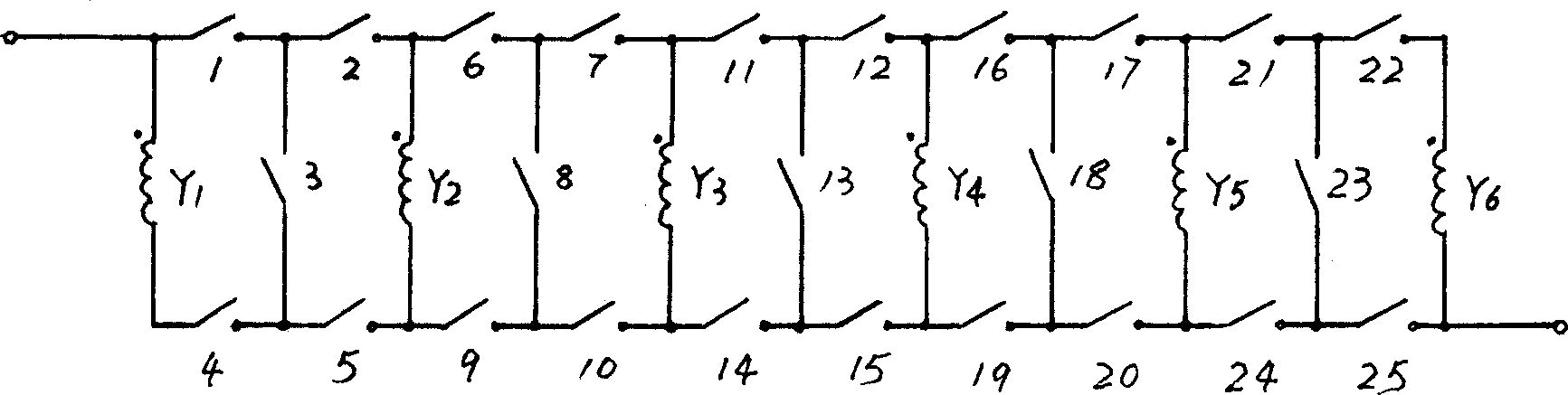

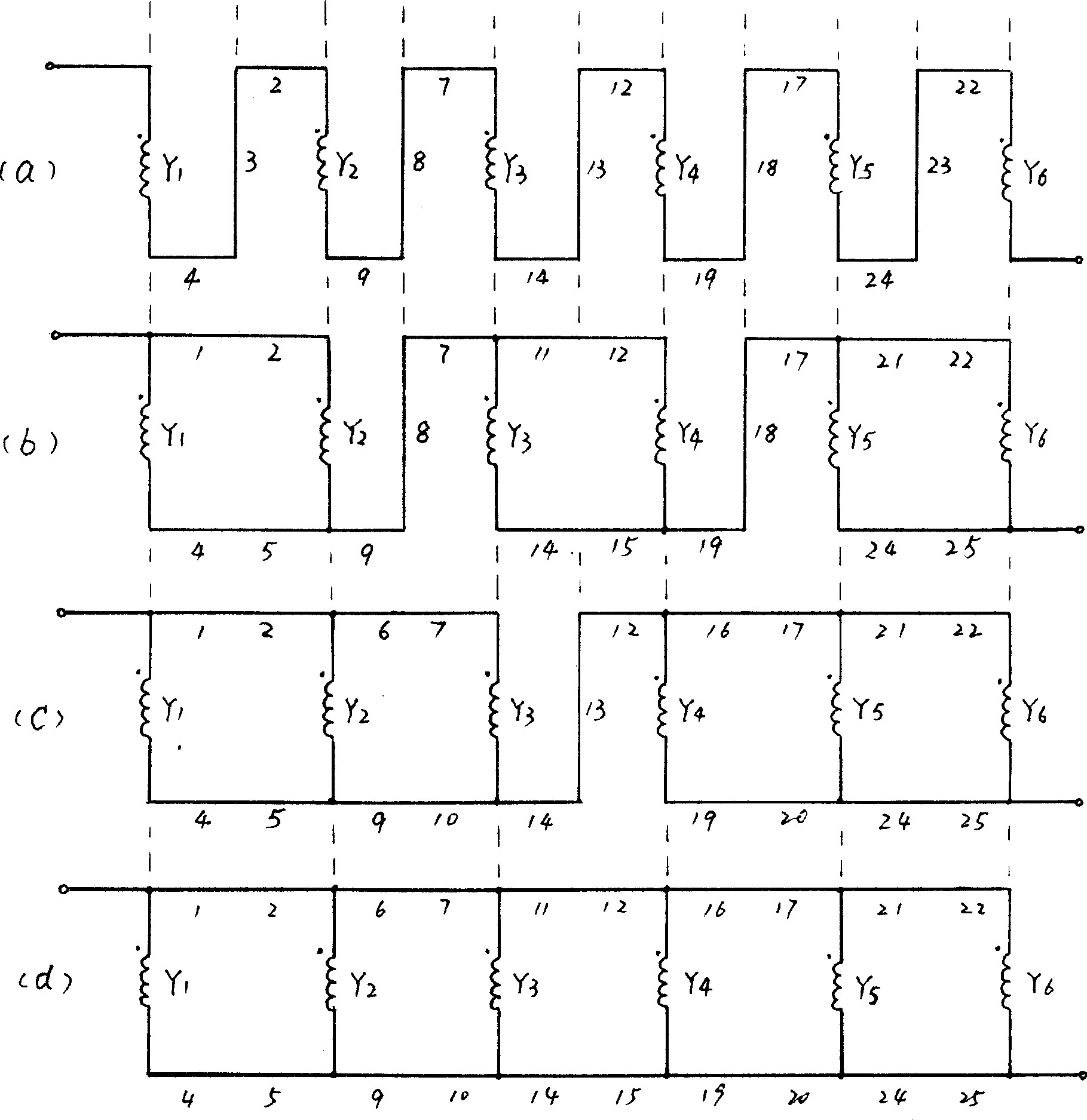

[0019] Example 2: Divide each coil element in a generator stator winding into six discrete sub-element sections. The sub-elements in each element are located in the same stator slot, have the same electrical structure and independent terminal sets. An electric control switch array is connected between the connection terminals of every two adjacent sub-elements. The electronically controlled switch array is five switches controlled by a computer program, and each switch is respectively located between two nodes on the "I" connecting line and between each node and the line end. Such as figure 2 Shown, Y 1 -Y 6 It is six discrete sub-elements in one coil element, occupies the same stator slot, has an independent terminal group, and has the same electrical structure. In child element Y 1 with Y 2 There are five switches 1-5 controlled by computer programs indirectly, forming an array of electronically controlled switches. Similarly, switches 6-10 are subcomponents Y 2 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com