Cultivator

A cultivator and rack technology, applied in the field of cultivators, can solve the problems of being stuck in a deep quagmire, inconvenient to operate, inconvenient to walk, etc., and achieve the effects of convenient operation, convenient cleaning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

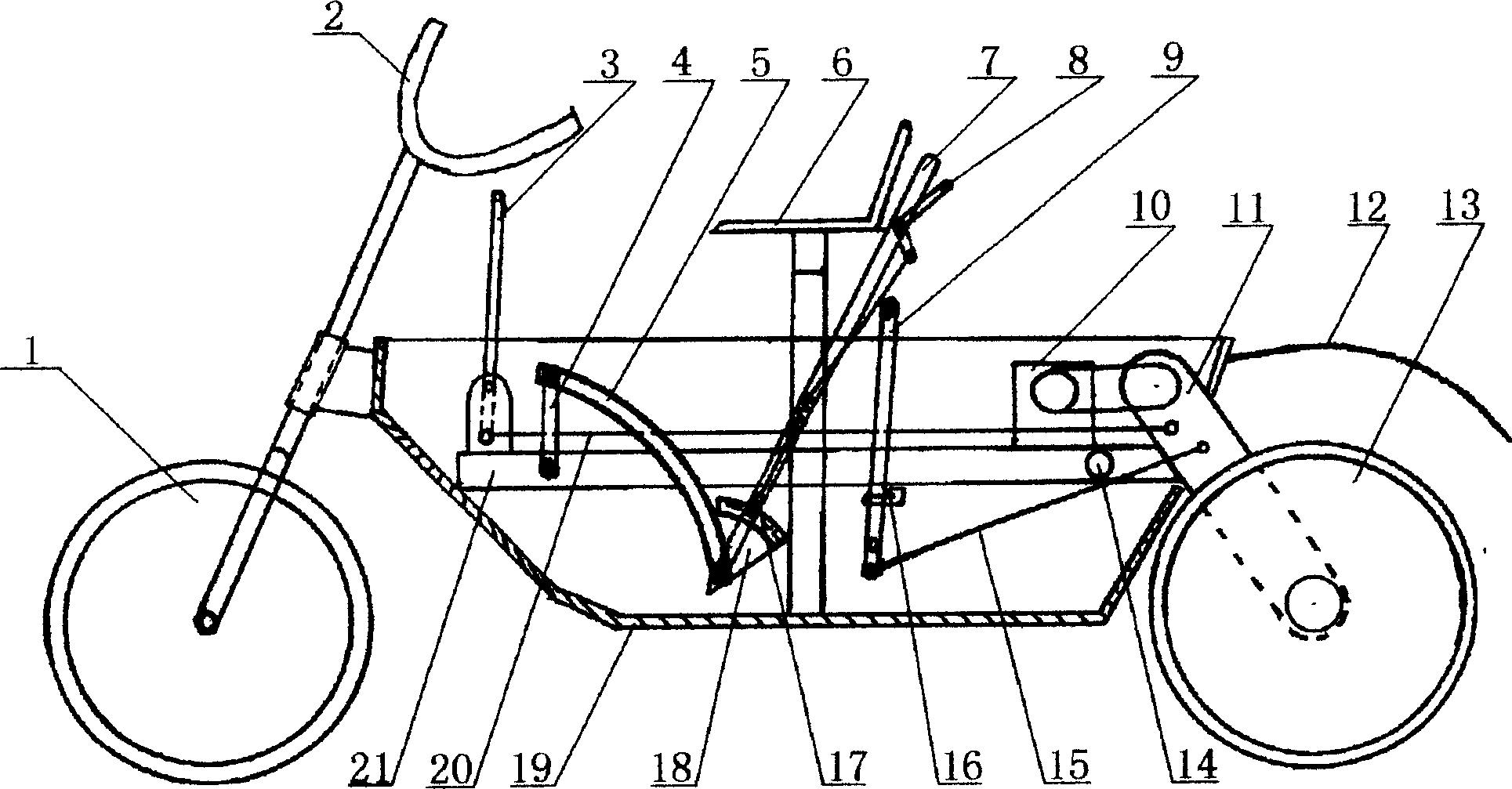

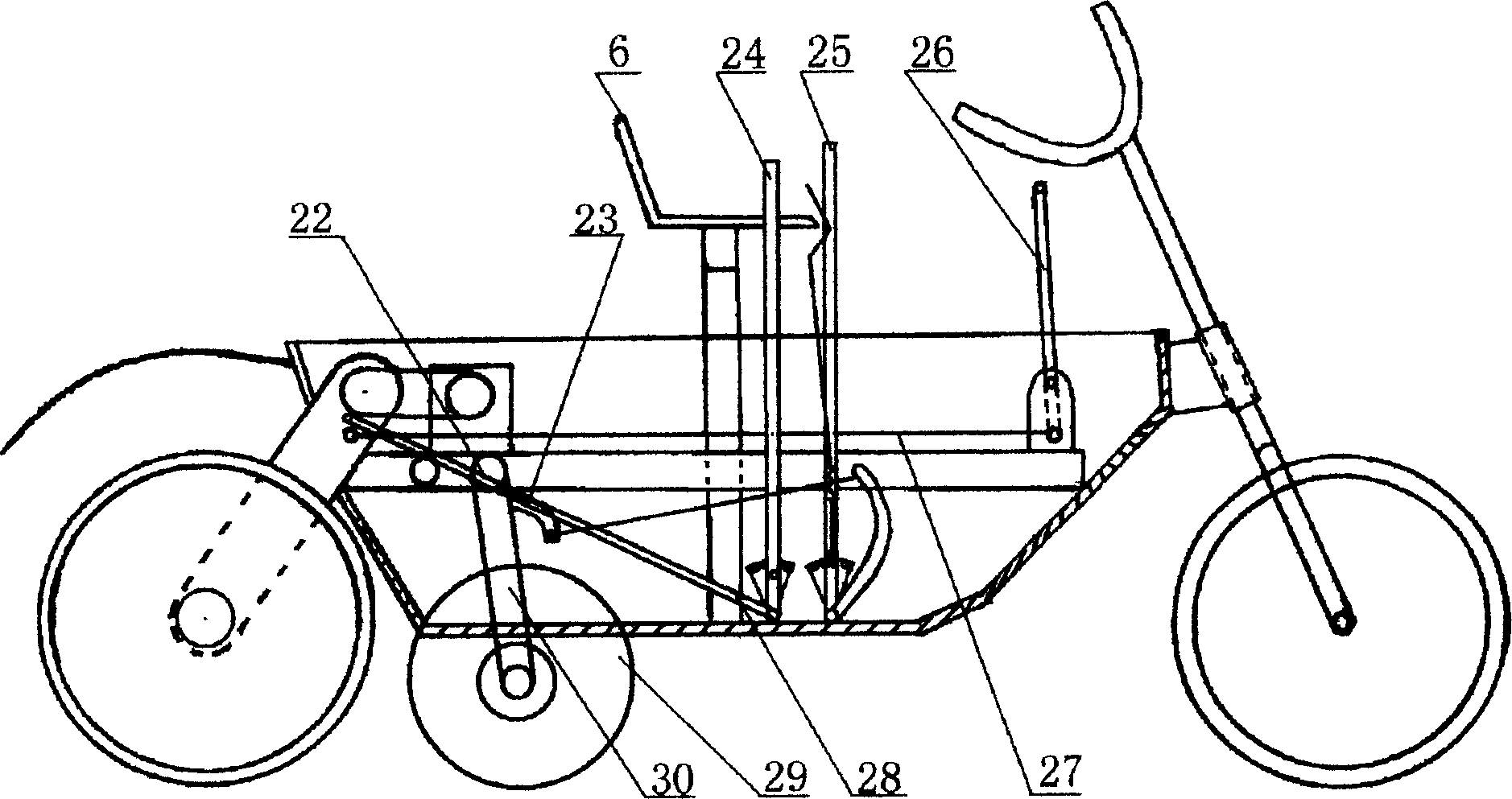

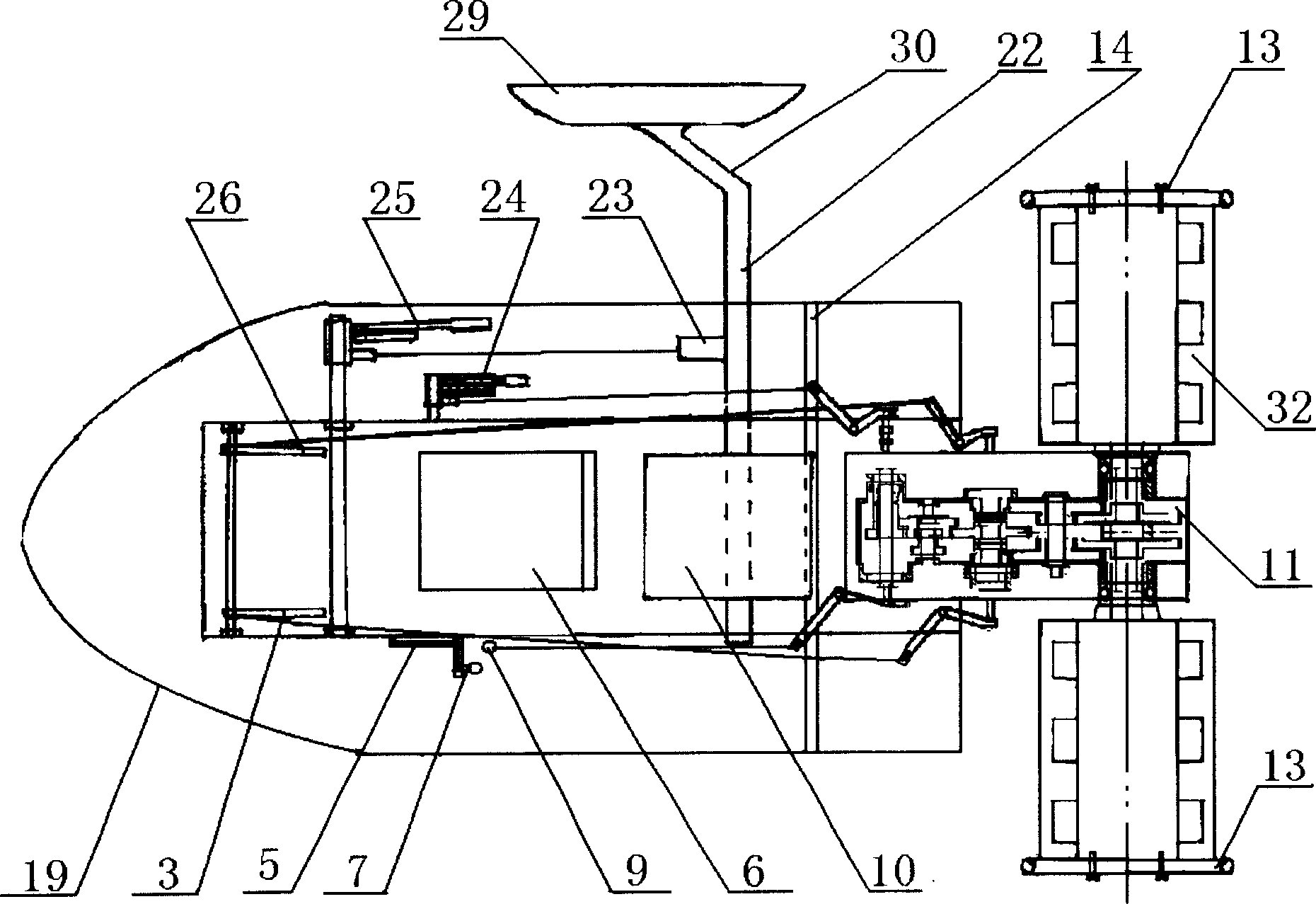

[0015] Depend on Figure 1 to Figure 7 It can be seen that it includes a hull 19, a gearbox 11 installed on the rear end of the hull 19, and rollers 32 that are sleeved on both sides of the gearbox 11 and turn out the shaft. When farming, the power unit drives the rollers 32 through the gearbox 11 to rotate, so that the rollers 32 side volume mud cultivations drive hull 19 to advance or retreat. Frame 21 is hinged with hull 19 by the frame rotating shaft 14 that is installed in hull 19 rear portions, and the lower end of frame boom 4 is hinged with the front portion of frame 21, and the frame boom 4 upper end is with frame boom 5 front ends. Hinged, the other end of the frame boom 5 is affixed to the frame elevating joystick 7 through a rotating shaft or directly. The two ends of the roller body 36 of the fixed roller 32 on the left and right output shafts of the gearbox 11 both sides are enclosed, so that the roller body 36 increases buoyancy and is convenient for cleaning. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com