A unit for adjusting clamping force for a vice

A technology for adjusting devices and clamping force, which is applied in vices, positioning devices, transmission devices, etc., and can solve problems such as damage to workpieces, large losses, and reduced processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

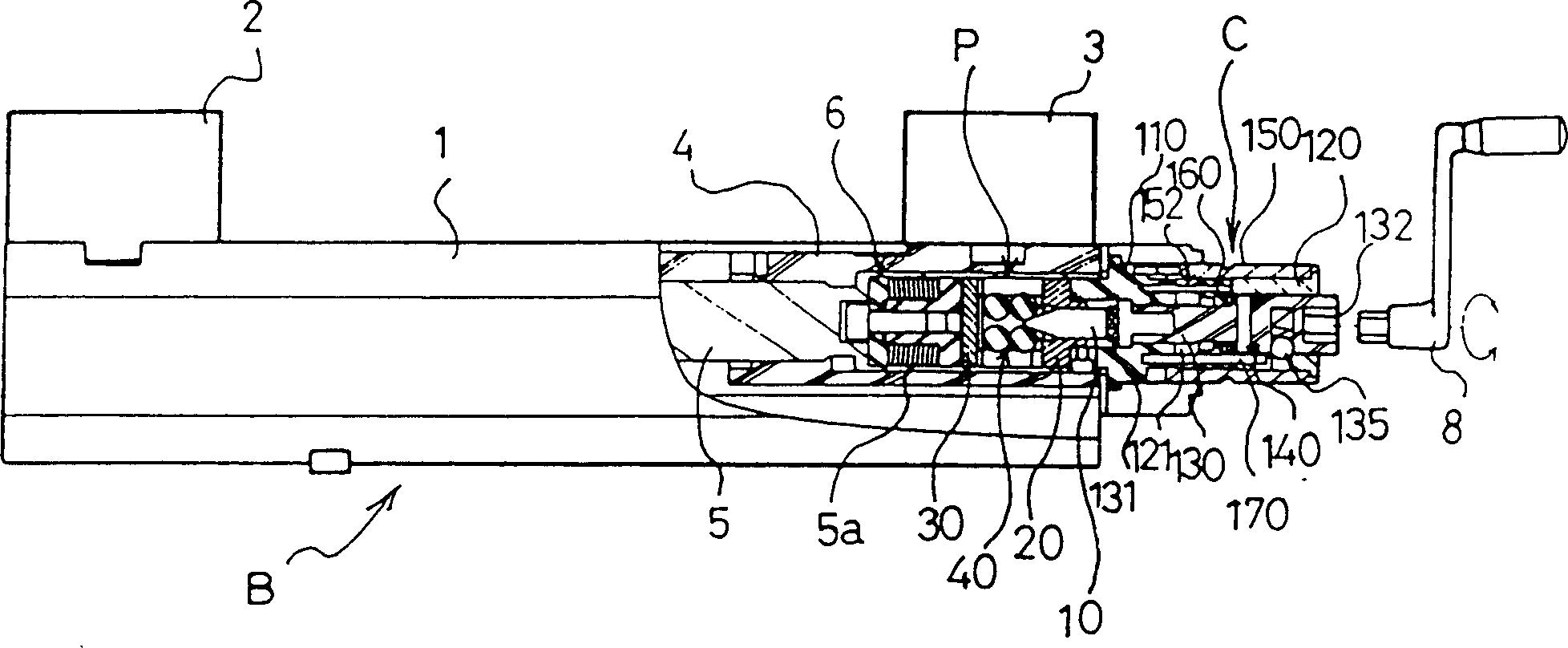

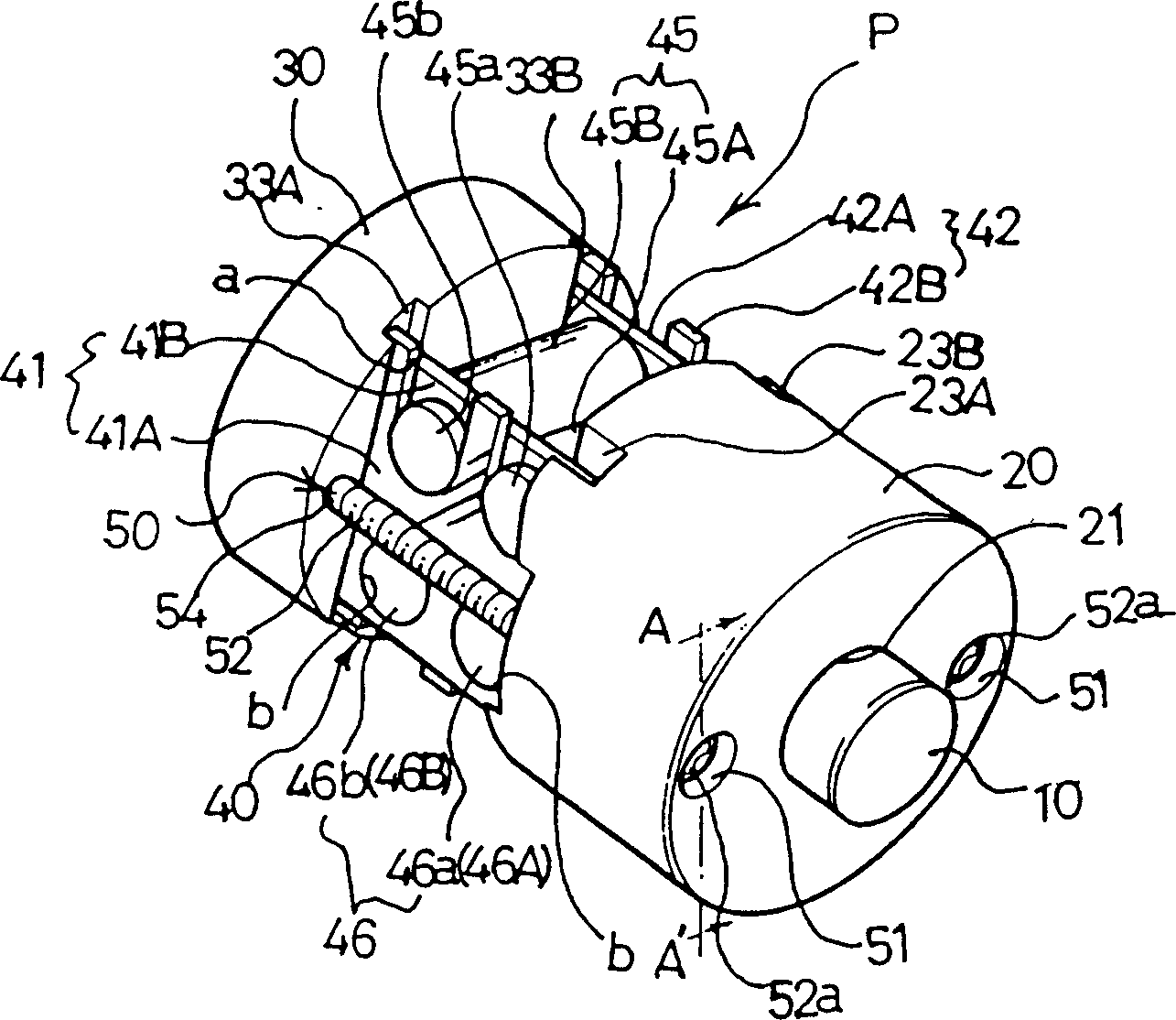

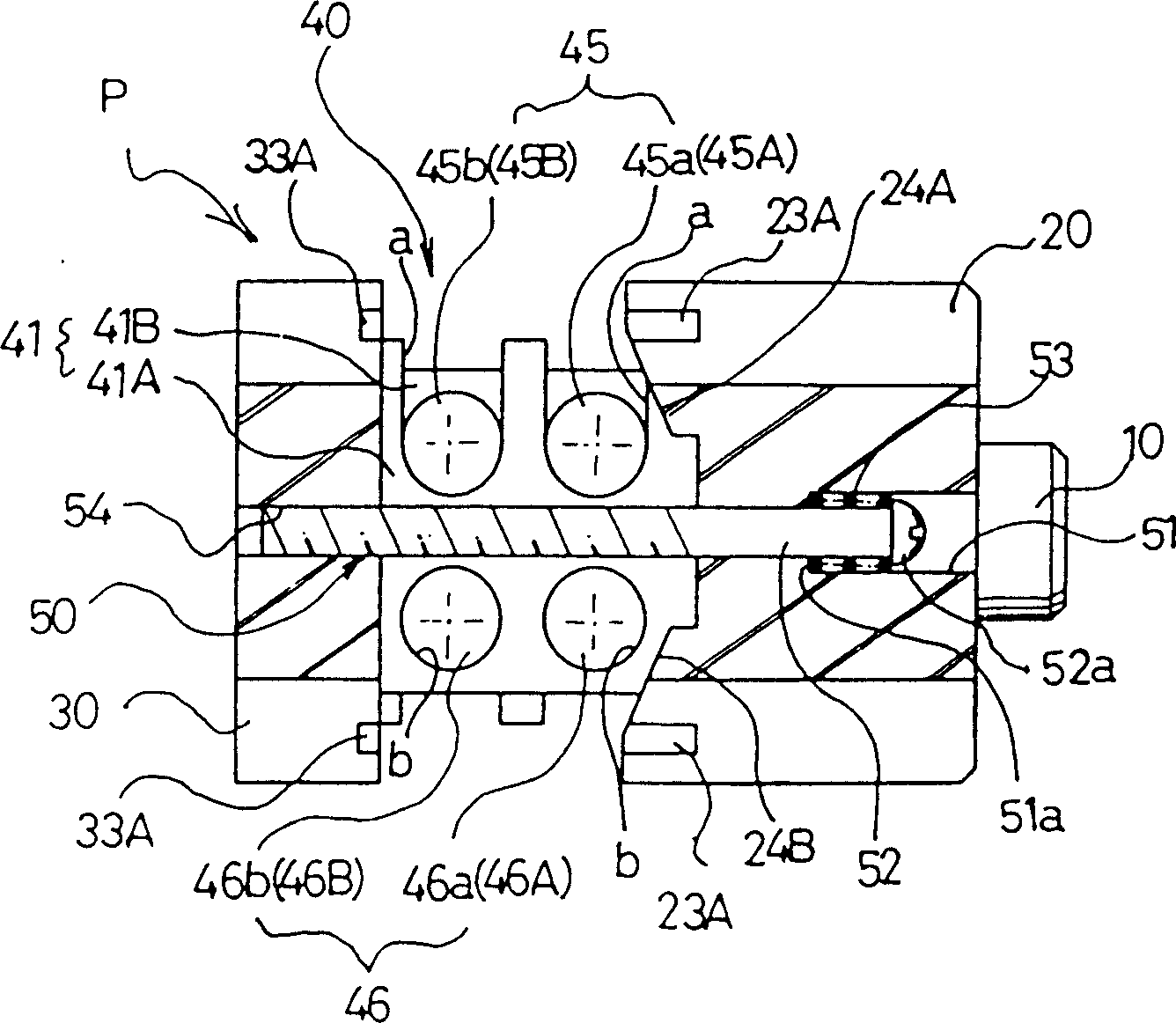

[0033] The force applying device P of the first embodiment is generally as Figure 2 ~ Figure 4 As shown, it is composed of a first moving part 10 , a holding part 20 , a second moving part 30 , a force part 40 and a clamping device 50 .

[0034] The first moving part 10 is in the shape of a round rod, and its front end forms a sharp wedge shape (conical shape in this embodiment) forming an acute angle.

[0035] The holding member 20 is substantially cylindrical, and a shaft hole 21 is formed at the center thereof through which the first moving member 10 can pass and can move back and forth freely. In addition, on one end surface of the above-mentioned holding member 20, there are formed first and second guide grooves 23A, 23B which are symmetrical to the diameter and are respectively parallel to the diameter with any one diameter passing through the shaft hole 21 as the center line. Between the two first guide grooves 23A and the second guide grooves 23B, flat first and seco...

no. 2 example

[0061] Below, refer to Figure 6 A second embodiment of the urging device P of the present invention will be described.

[0062] The urging device P of the second embodiment, except that no inclined surface is formed on the holding member 20 contacting the front upper roller 45A and the front lower roller 46A, only moves in the second contact with the rear upper roller 45B and the rear lower roller 46B. Except that the inclined surfaces 34A, 34B are formed on the member 30, other configurations are the same as those of the urging device P of the first embodiment. Therefore, the same components as those in the first embodiment are assigned the same reference numerals, and description thereof will be omitted.

[0063] Such as Figure 6 As shown, in the second embodiment, the holding part 20 is roughly cylindrical, and a shaft hole 21 through which the first moving part 10 passes and can move back and forth freely is formed in the center. Any one of the diameters passing throu...

no. 3 example

[0066] Below, refer to Figure 7 A third embodiment of the urging device P of the present invention will be described.

[0067] In the urging device P of the third embodiment, the inclined surfaces 24A, 24B and the inclined surfaces 34A, 34A, Except for 34B, other constitutions are the same as those of the urging device P of the first and second embodiments. Therefore, the same components as those in the first and second embodiments are assigned the same reference numerals, and description thereof will be omitted.

[0068] Such as Figure 7 As shown, in the third embodiment, the holding part 20 forms a shaft hole 21 in the center that allows the first moving part 10 to pass through and move back and forth freely. Any diameter of the hole 21 is used as the center line, and the first and second guide grooves 23A, 23B parallel to the above-mentioned diameters are formed respectively between the above-mentioned first guide groove 23A and the second guide groove 23B from the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com