Anti-fake package bottle and its making process

A manufacturing process and anti-counterfeiting packaging technology, applied in the field of manufacturing process of packaging bottles and plastic anti-counterfeiting packaging bottles, can solve the problems of easy falling off, imperfect legal system, easy forgery, etc., and achieve the effect of not falling off easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

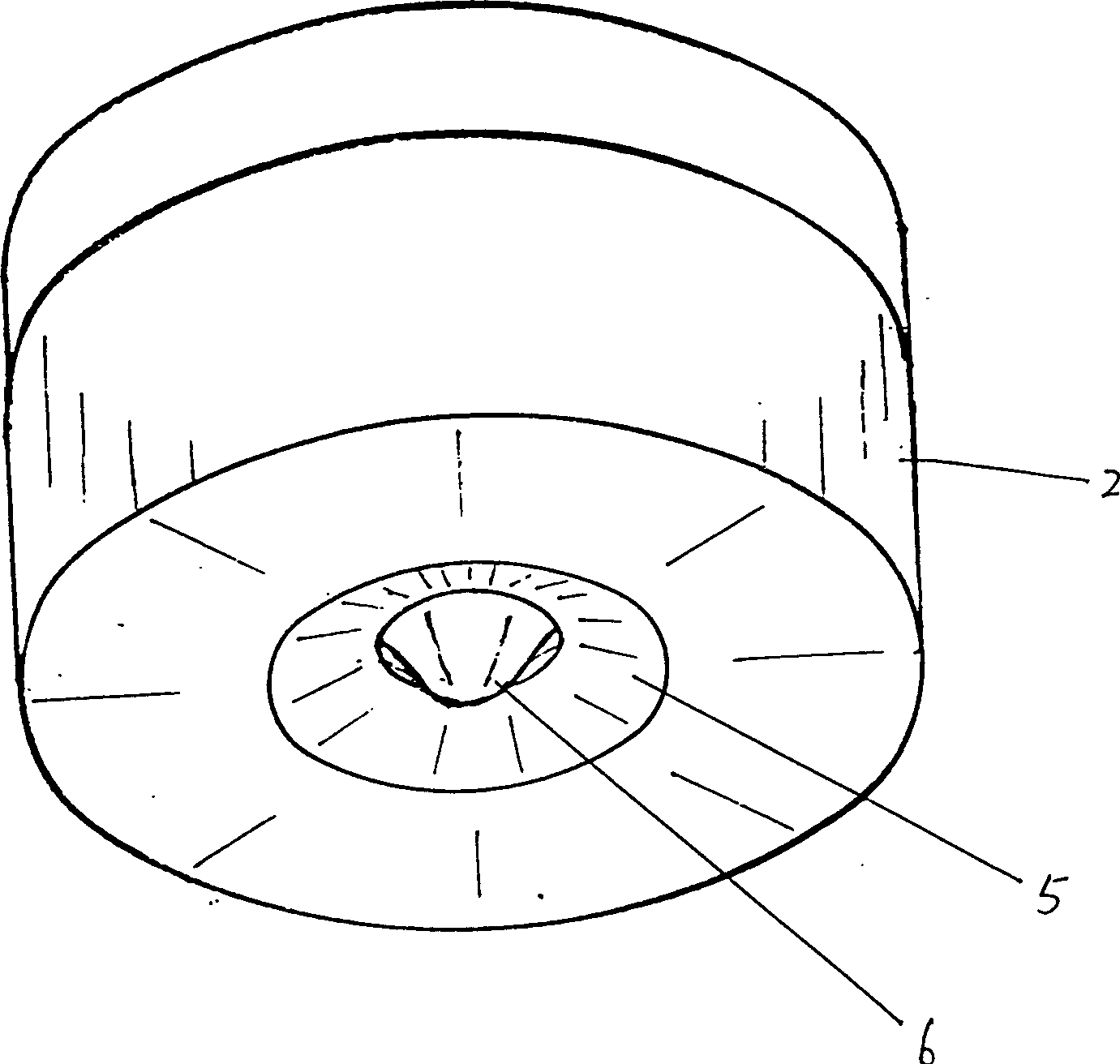

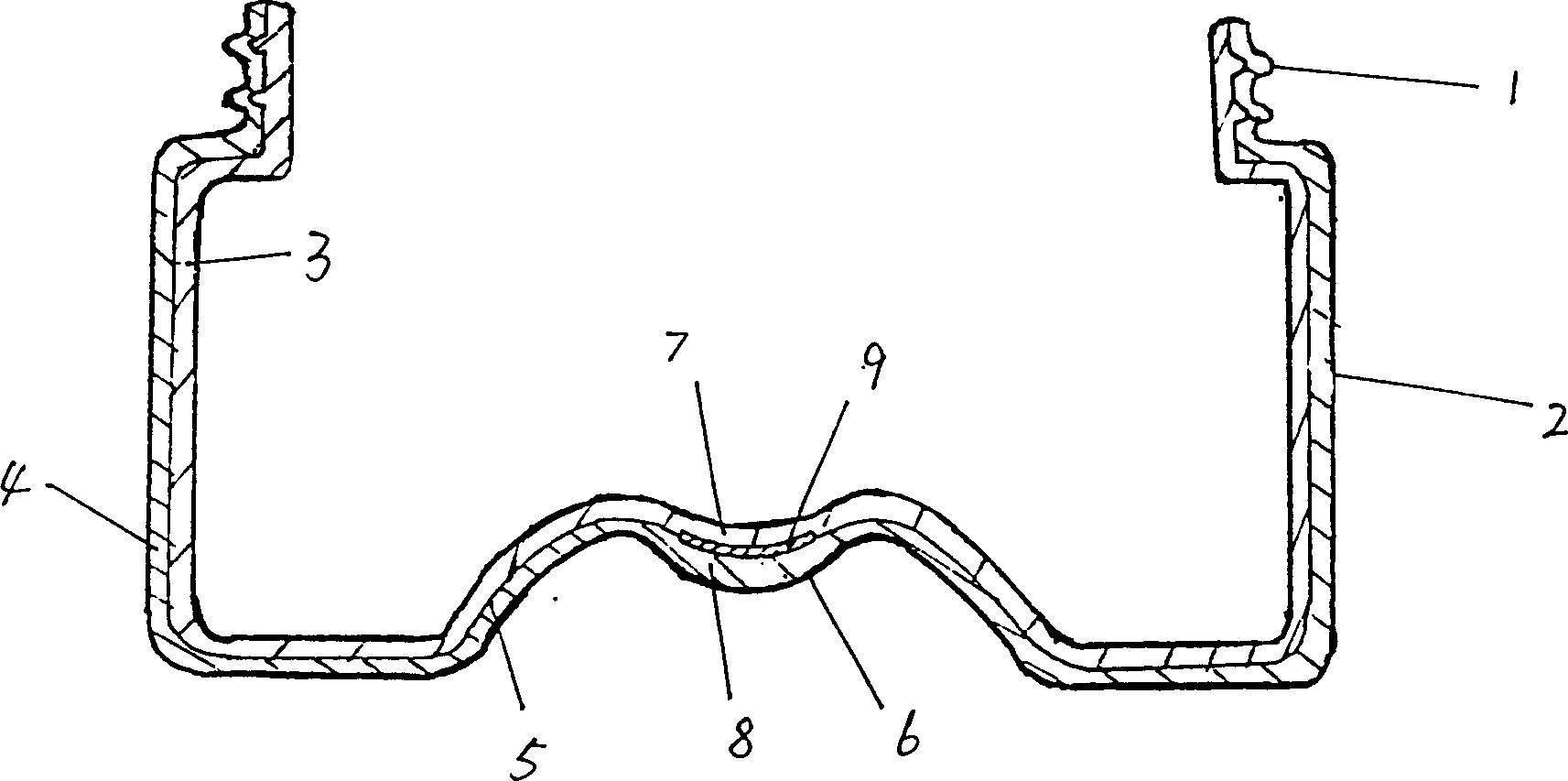

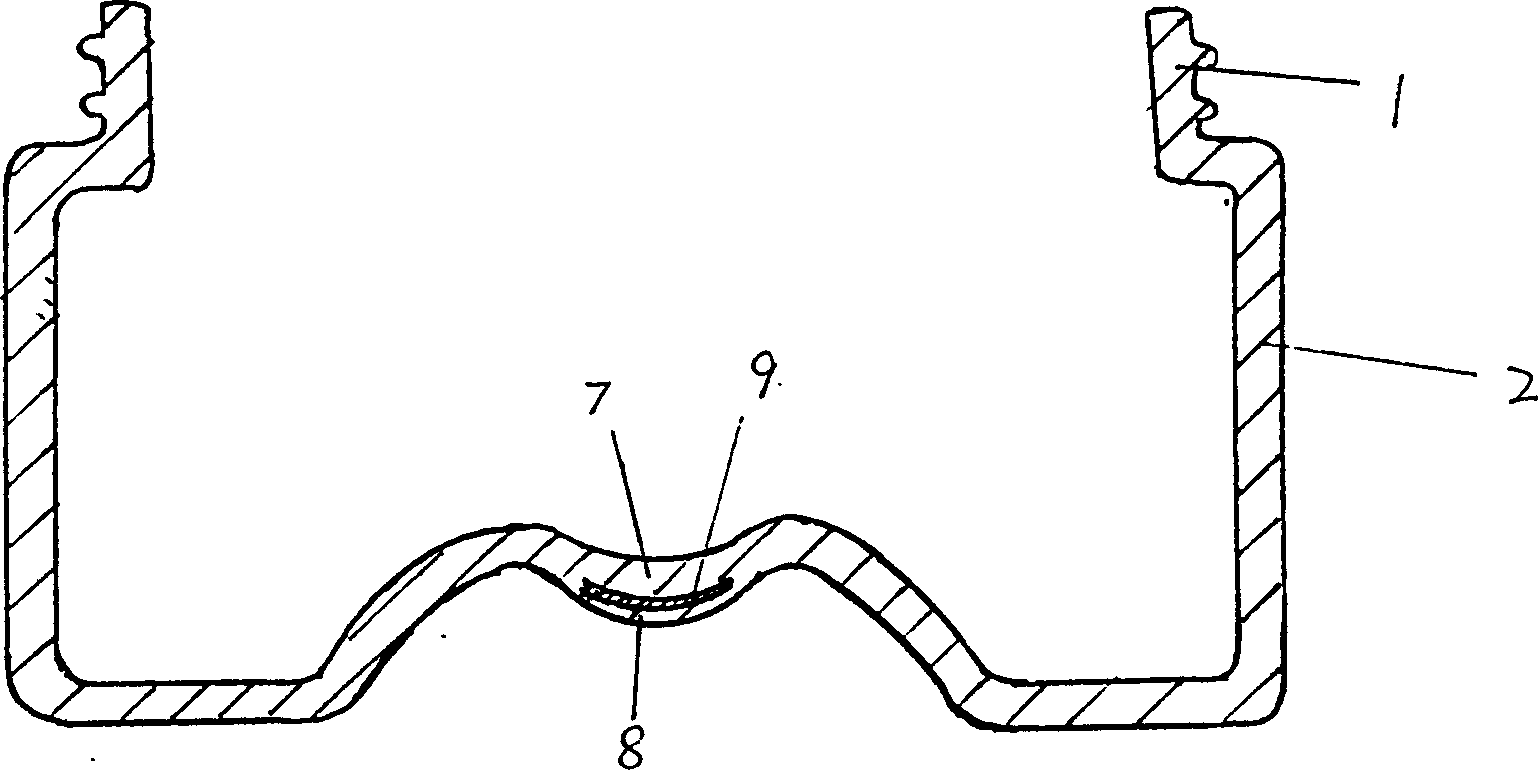

[0025] Such as figure 1 , 2 As shown, the anti-counterfeit packaging bottle includes a bottle mouth 1 and a bottle body 2, the bottle mouth and the bottle body of the packaging bottle are all double-layer structures, and the inner wall 3 is colored polyethylene terephthalate (PET) , the outer wall 4 is transparent PET, the middle of the bottom of the packaging bottle forms a hemispherical convex surface 5 upwards, and the central area of the convex surface forms a hemispherical surface 6 downwards. The hemispherical surface has a three-layer structure, and the inner layer 7 is connected with the inner wall 3 of the bottle. , the outer layer 8 is integrated with the outer wall of the bottle body 4, and the middle layer is an anti-counterfeit label 9. The manufacturing process is as follows: (1) pouring colored PET in a molten state into the injection molding mold of the bottom embryo, and obtaining the bottom embryo with a bottle mouth and a bottle body through injection mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com