Rubber composition with high dielectric constant and electric cable member

A rubber composition and high dielectric constant technology are applied in the fields of high dielectric constant rubber compositions and power cable components, and can solve the problem of reduced insulation, high polarity of rubber polymer, reduced insulation breakdown voltage or insulation resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention will be described in detail below.

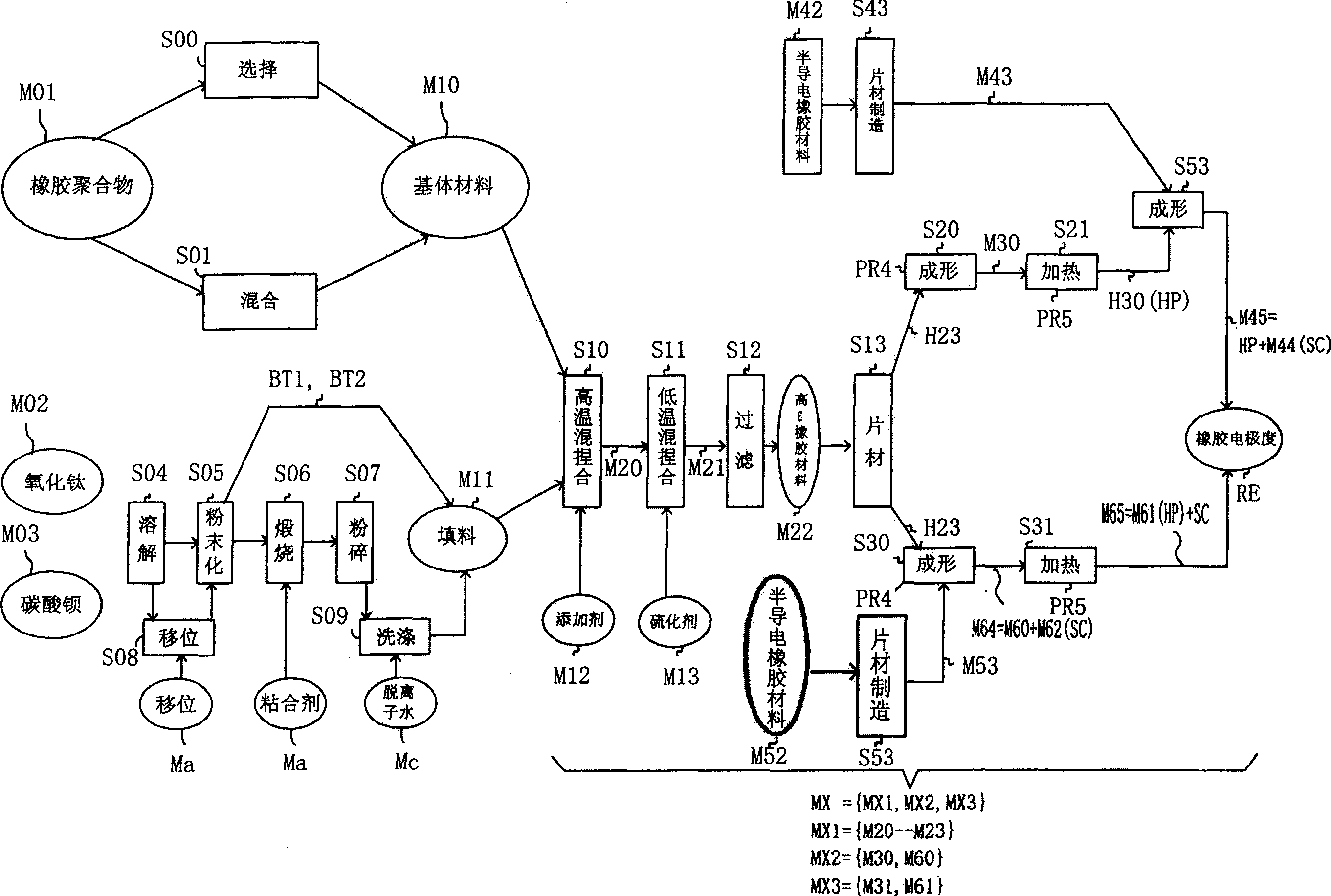

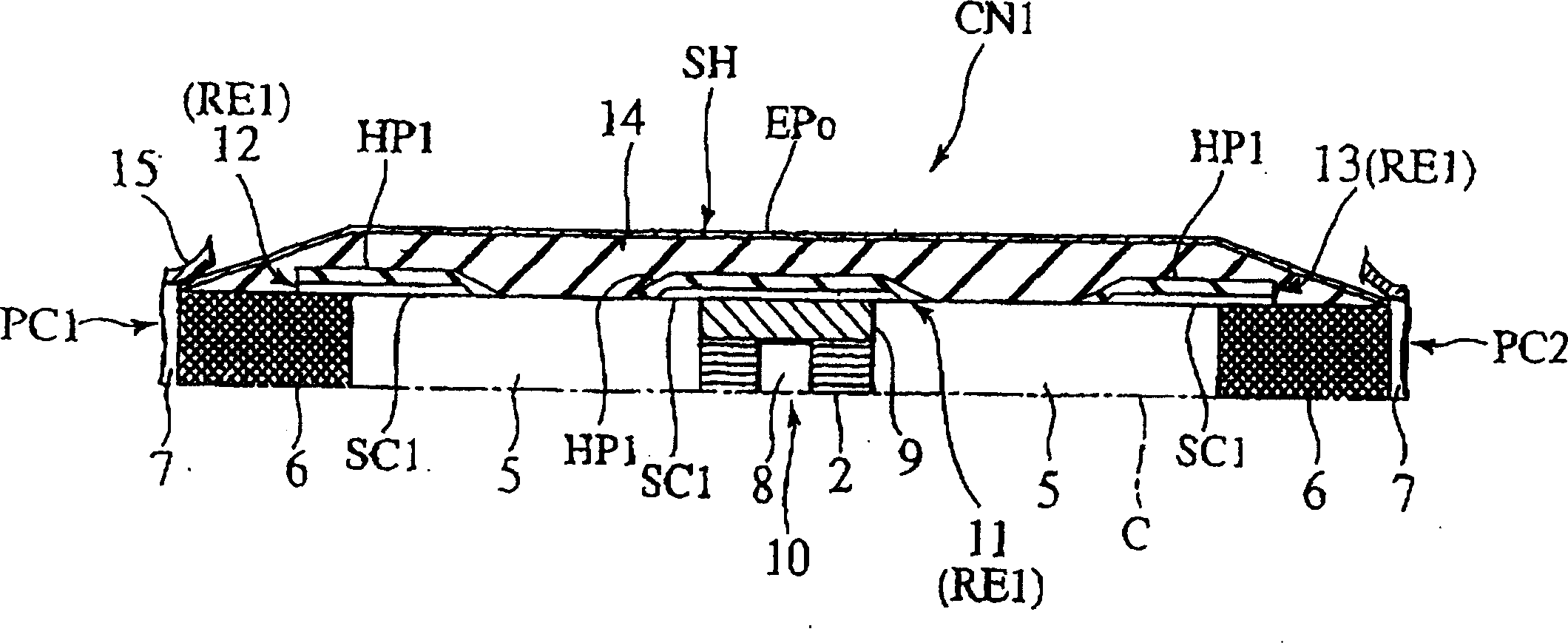

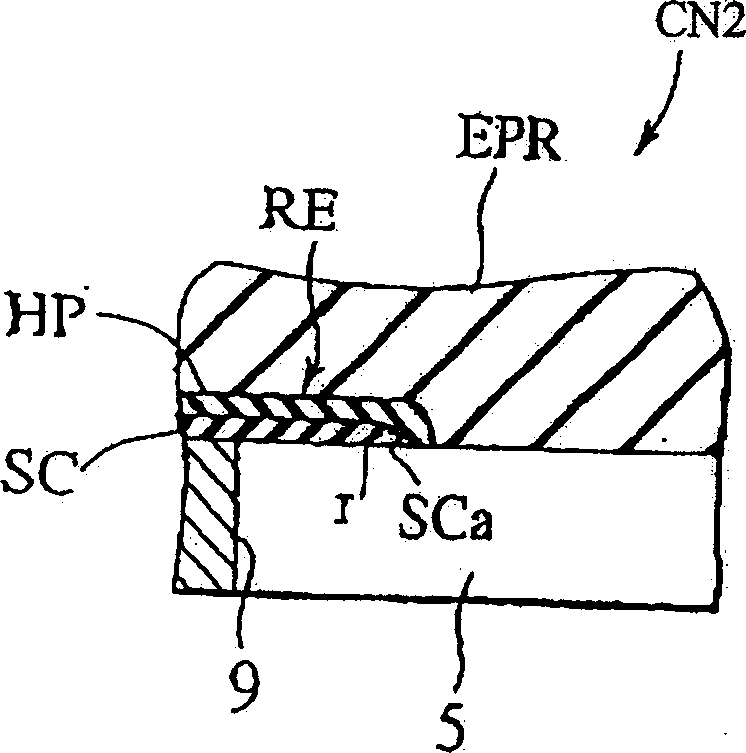

[0065] figure 1 It represents the production process PR of a group of high dielectric constant (dielectric constant above 10) rubber composition MX according to the embodiment of the present invention, and the manufacturing process MF of the box-type electrode layer RE of the power cable partly including this process PR .

[0066] The high dielectric constant rubber composition MX in this embodiment is the high dielectric constant vulcanized rubber material MX1 (hereinafter often referred to as "unvulcanized rubber material") in the unvulcanized state described later, the high dielectric constant rubber material before heat treatment MX2 (hereinafter often referred to as "vulcanized rubber material") and heat-treated high dielectric constant rubber material MX3 (hereinafter often referred to as "heat-treated rubber material") is a general term. Furthermore, the cartridge electrode layer RE in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap