Optical collimator structure

A collimator and optical technology, applied in the direction of optics, optical components, instruments, etc., can solve problems such as difficult to reduce manufacturing costs, high cost processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

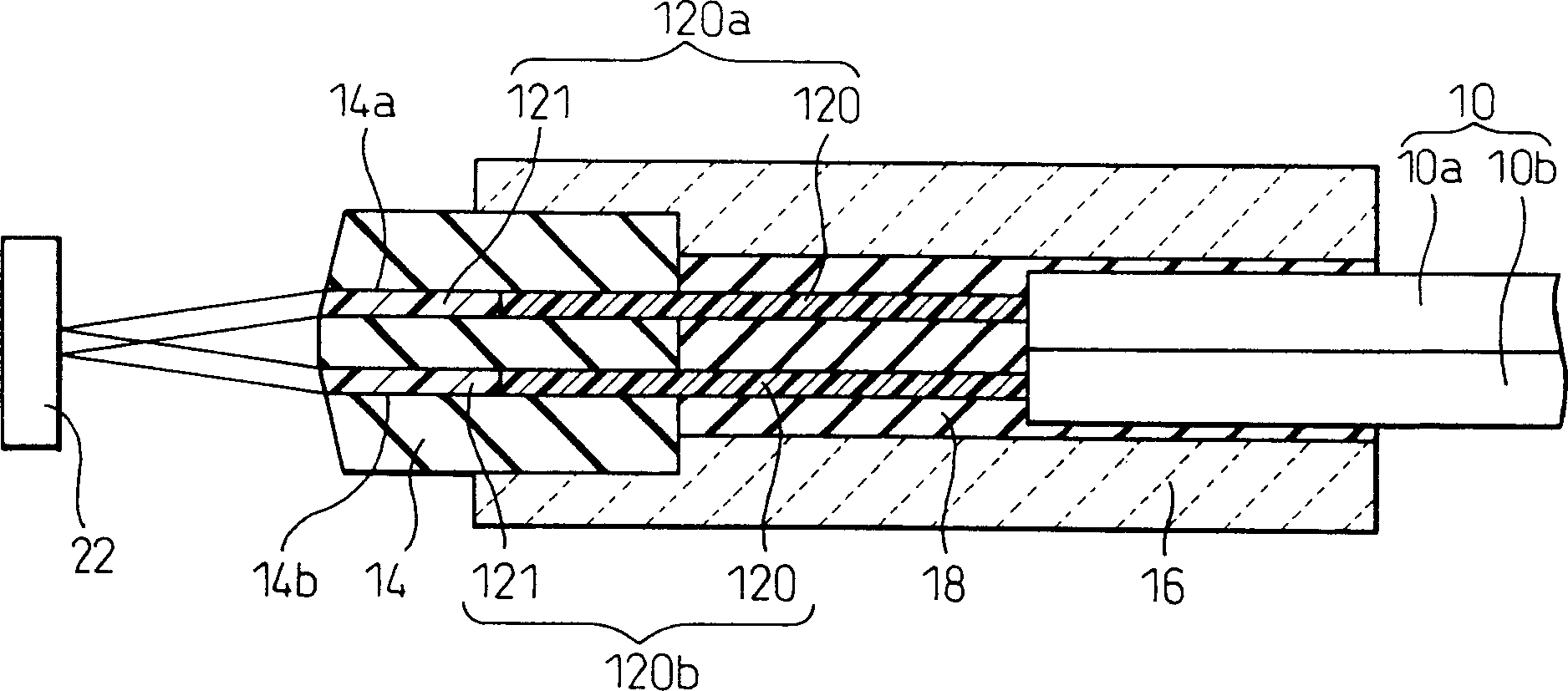

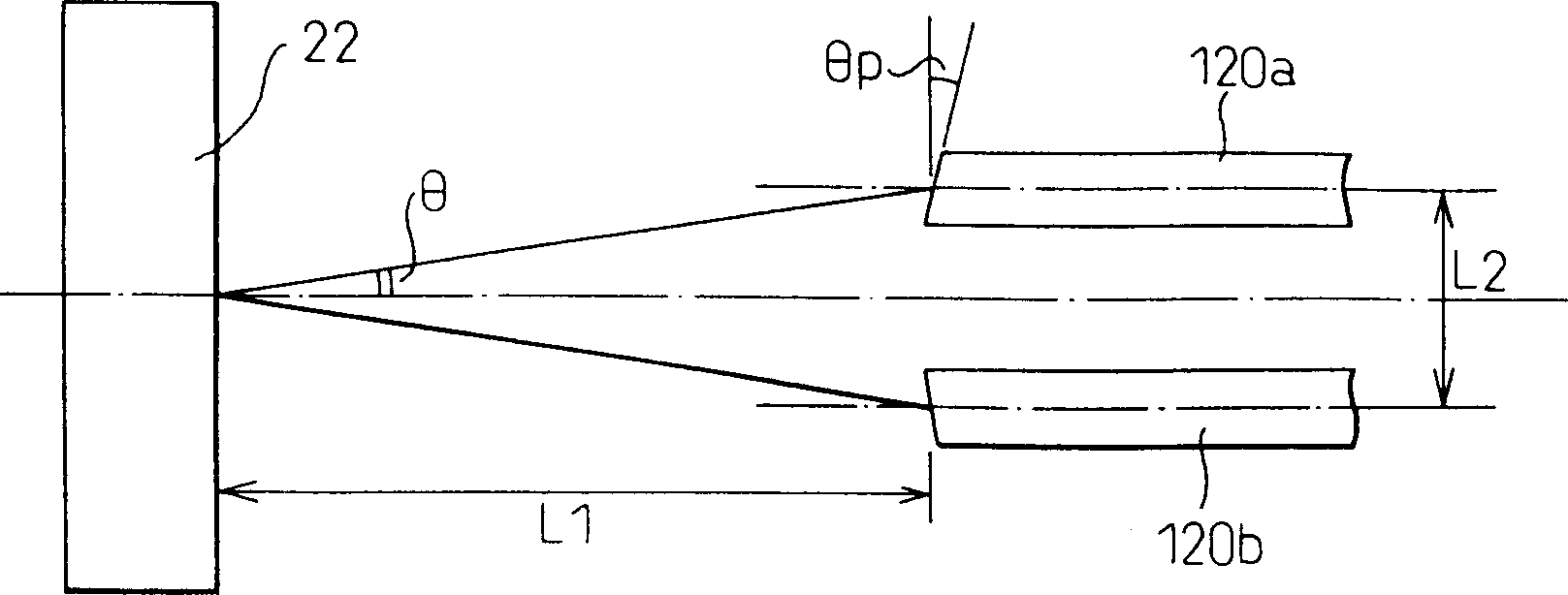

[0023] figure 1 Shown is the optical collimator structure of one embodiment of the present invention, described optical collimator structure is made with optical fiber assembly 10, and optical fiber assembly 10 comprises first unitary optical fiber (unitary optical fiber) 10a and a second unitary optical fiber 10b, They each have a core 120 . The optical collimator structure of the present invention is characterized in that the optical collimator structure is manufactured using an optical fiber assembly 10 having a graded-index optical fiber (GI optical fiber) 14a (or 14b), the GI optical fiber 14a ( or 14b) is welded to the end of the core 120 of each single mode fiber (SMFs) 10a, 10b forming the fiber optic assembly 10, so that each single mode fiber has an optical collimator structure.

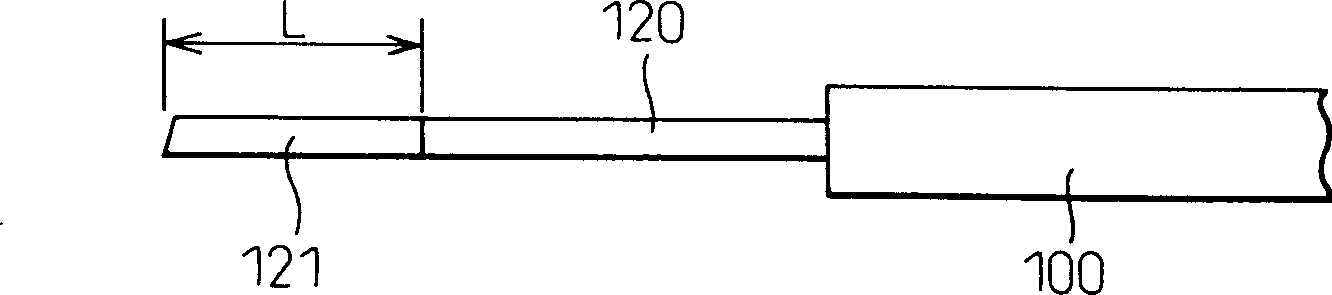

[0024] figure 2 An example of a single-core fiber collimator structure is shown in which a GI fiber 121 is welded to the end of the core 120 of the single-mode fiber 100 . In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com