Heat resistant insulative membrane and insulative method

A technology of heat-resistant insulation and film covering, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as unrealistic installation, poor stability, poor shape followability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described below.

[0018] The heat-resistant insulating film of this embodiment is a heat-resistant resin film represented by polyimide resin, such as polyimide, polyamide, polybenzimidazole, polyester, polyimidazole, polyphenylene Base sulfide, polyamideimide, polyetherimide, polyetherketone, polysulfone, etc.

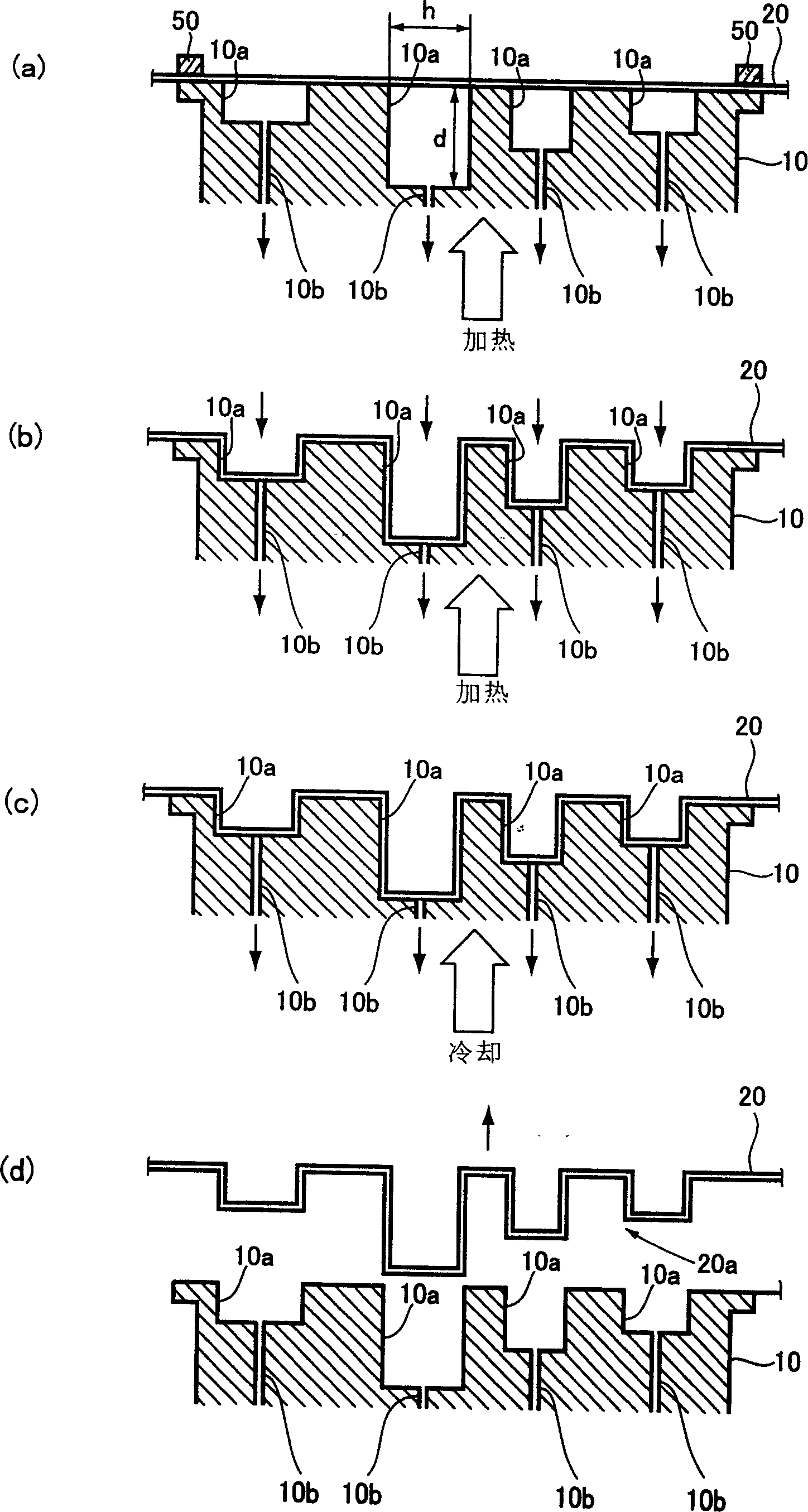

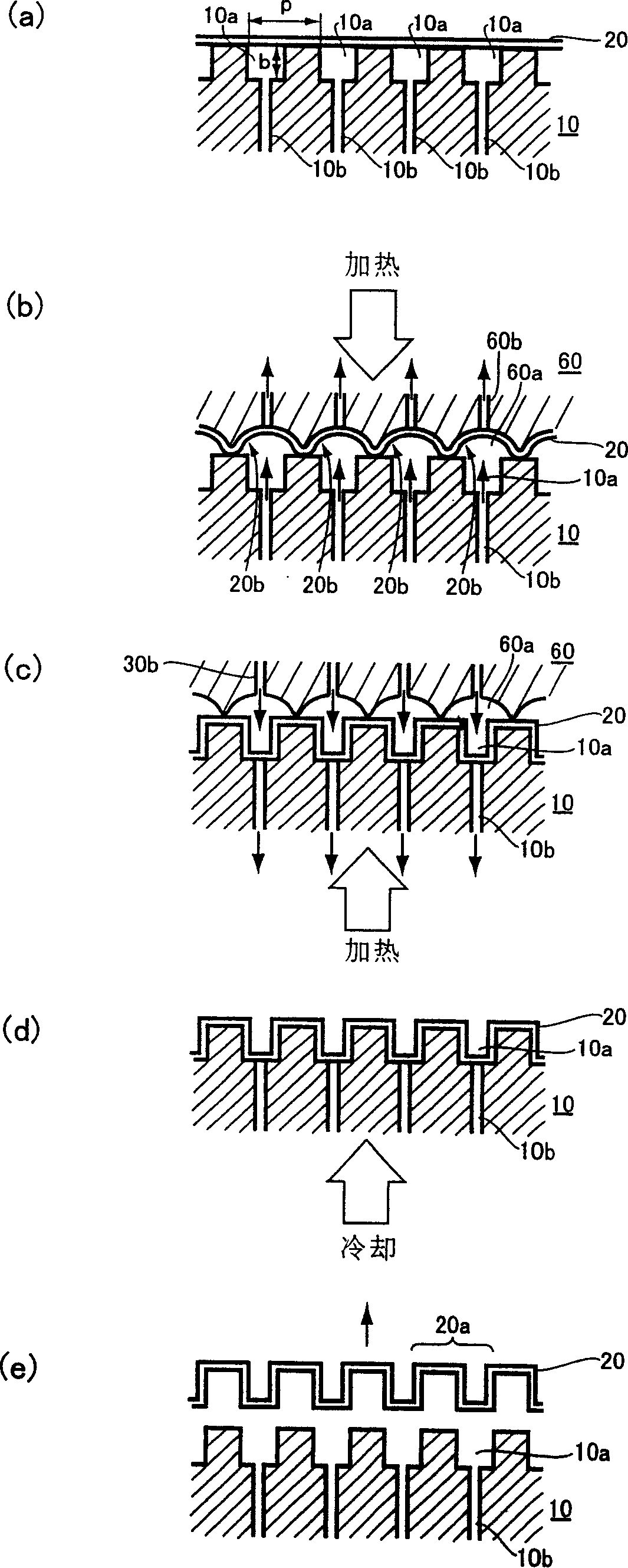

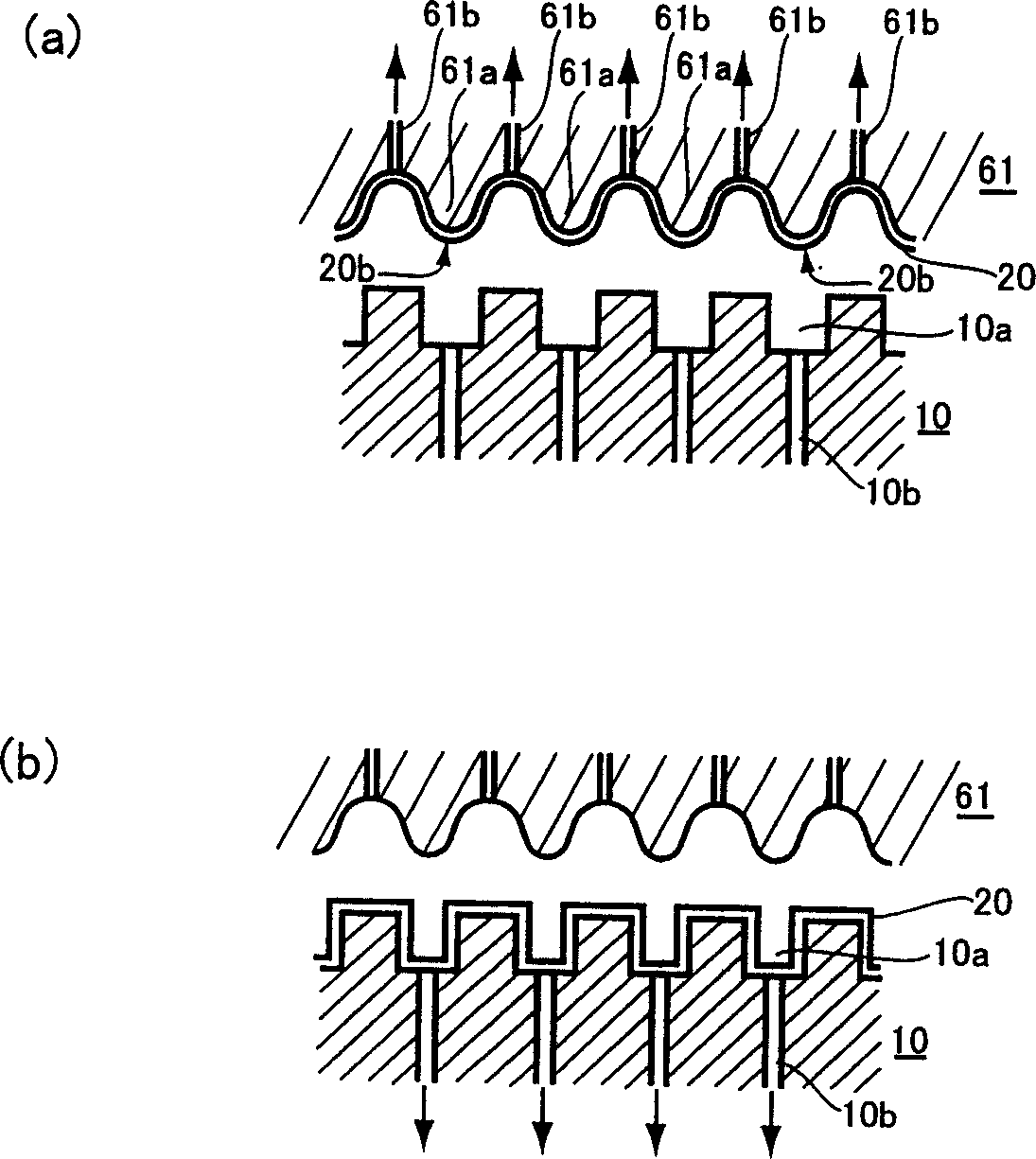

[0019] When a heat-resistant insulating film is provided on a structure including concave or convex portions, a shape pattern (hereinafter referred to as a concave-convex shape pattern) conforming to the shape can be formed by a three-dimensional molding method. Thereby, the heat-resistant insulating film can be easily installed on the object to be insulated. Firm installation can be realized even for insulating objects with surface shapes such as unevenness. In addition, the concavo-convex pattern formed on the heat-resistant insulating film is a concavo-convex pattern in which the ratio of the depth to the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com