Semiconductor device and mfg. method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of poor manufacturing efficiency and limited freedom of semiconductor chips, and achieve the effect of preventing leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the present embodiment, in each figure, different scales are used for each layer and each member so that each layer or each member can be seen clearly on the drawing.

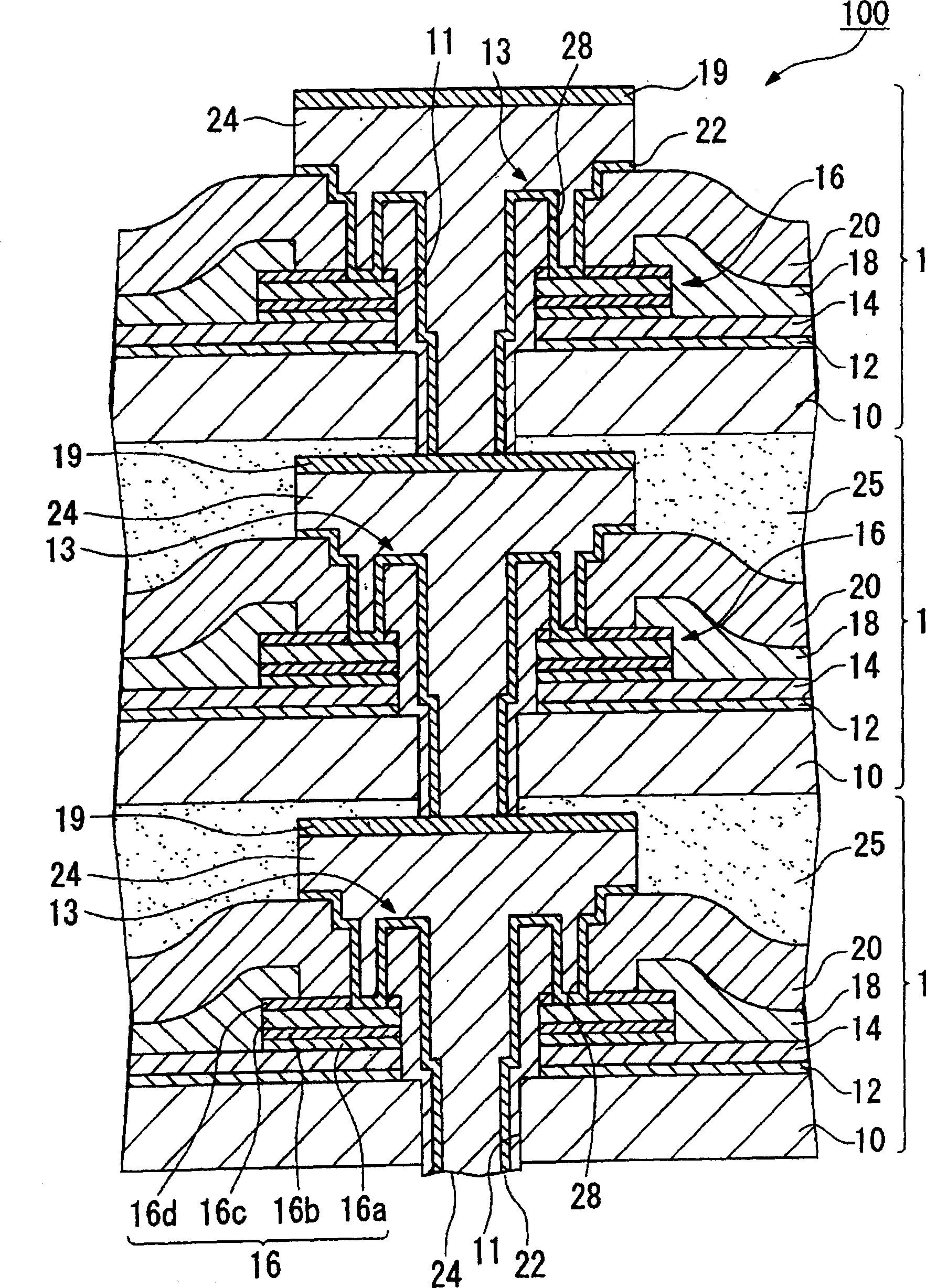

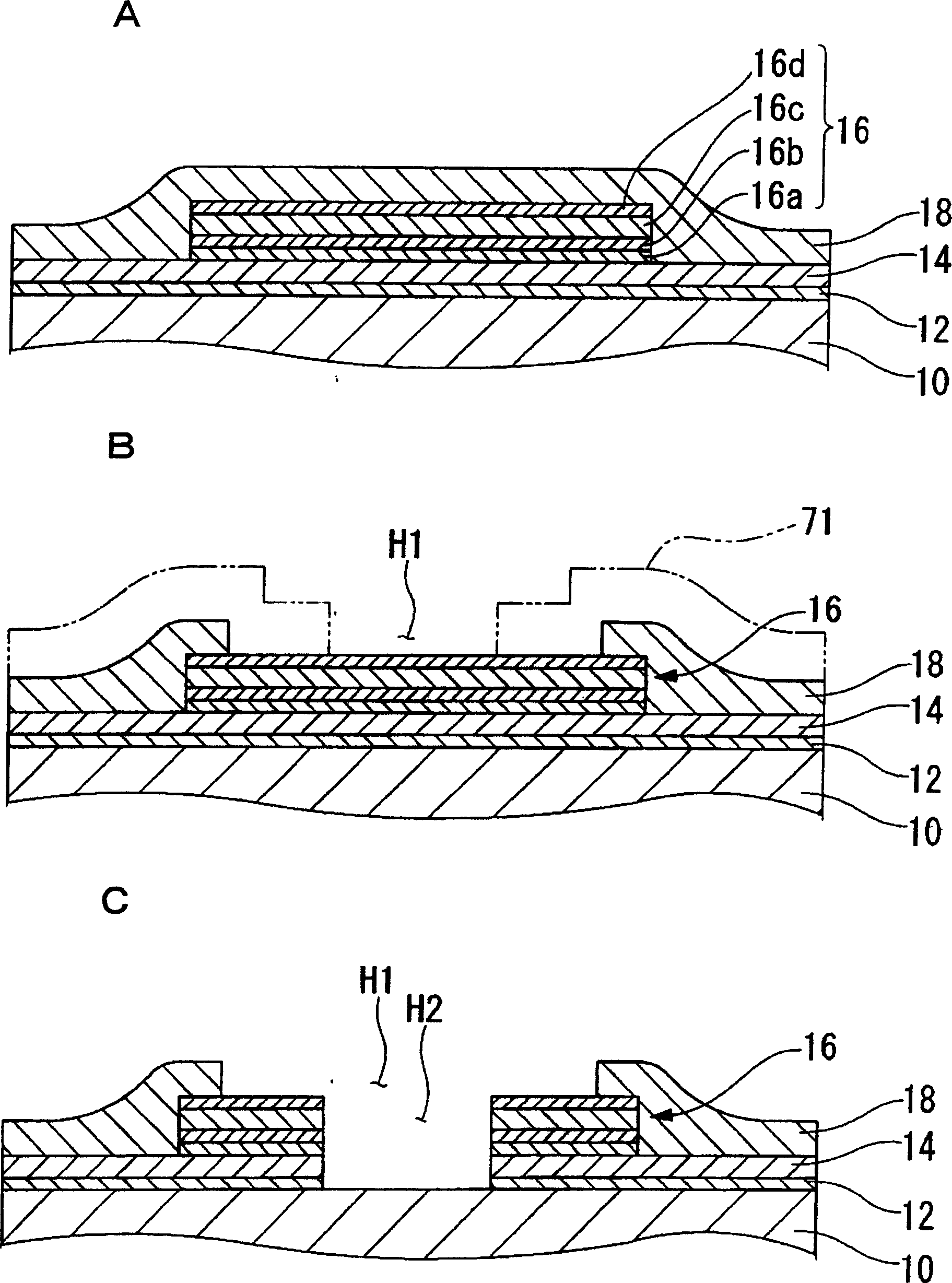

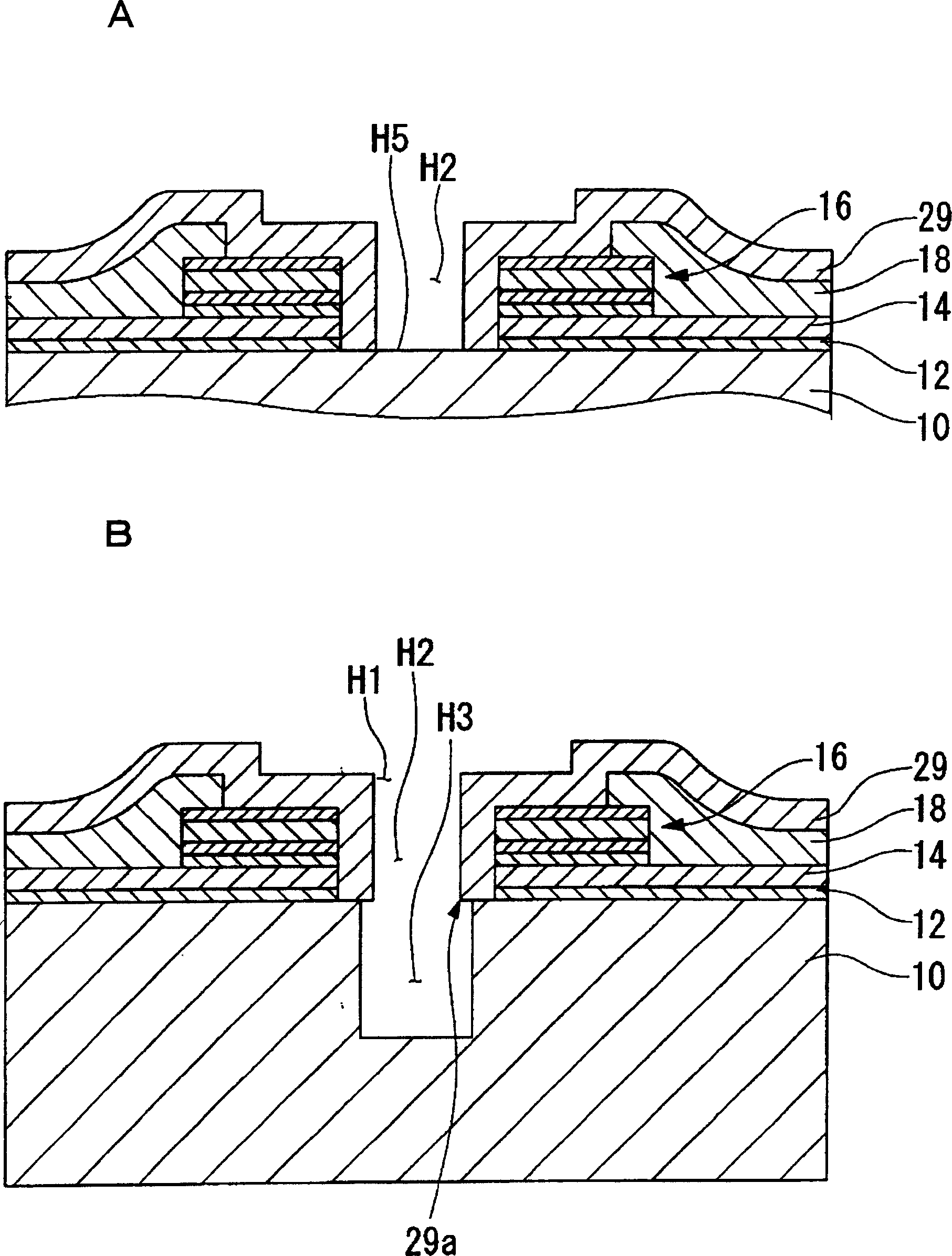

[0042] figure 1 A schematic cross-sectional view showing the main parts of the semiconductor device according to the first embodiment. A semiconductor device 100 is formed by stacking electrode pads on a silicon substrate 10 with an insulating film 12 formed of a thermally oxidized film and an interlayer insulating film 14 formed of SiO2. 16 is formed by three-dimensionally mounting the semiconductor device main body 1 .

[0043] The semiconductor device main body 1 is formed by laminating an insulating film 12 with a thickness of about 4000 Å, an interlayer insulating film 14 with a thickness of about 10000 Å, and an electrode pad 16 with a thickness of about 8000 Å on a silicon substrate 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com