Cylinder cap structure

A technology of cylinder head and cylinder block, applied in the direction of cylinder head, cylinder, jet propulsion device, etc., can solve the problems of inability to spread oil flow and leakage flow, increase of oil consumption, and deterioration of exhaust gas, etc. The effect of smooth supply, prevention of deterioration of exhaust gas, and prevention of deterioration of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

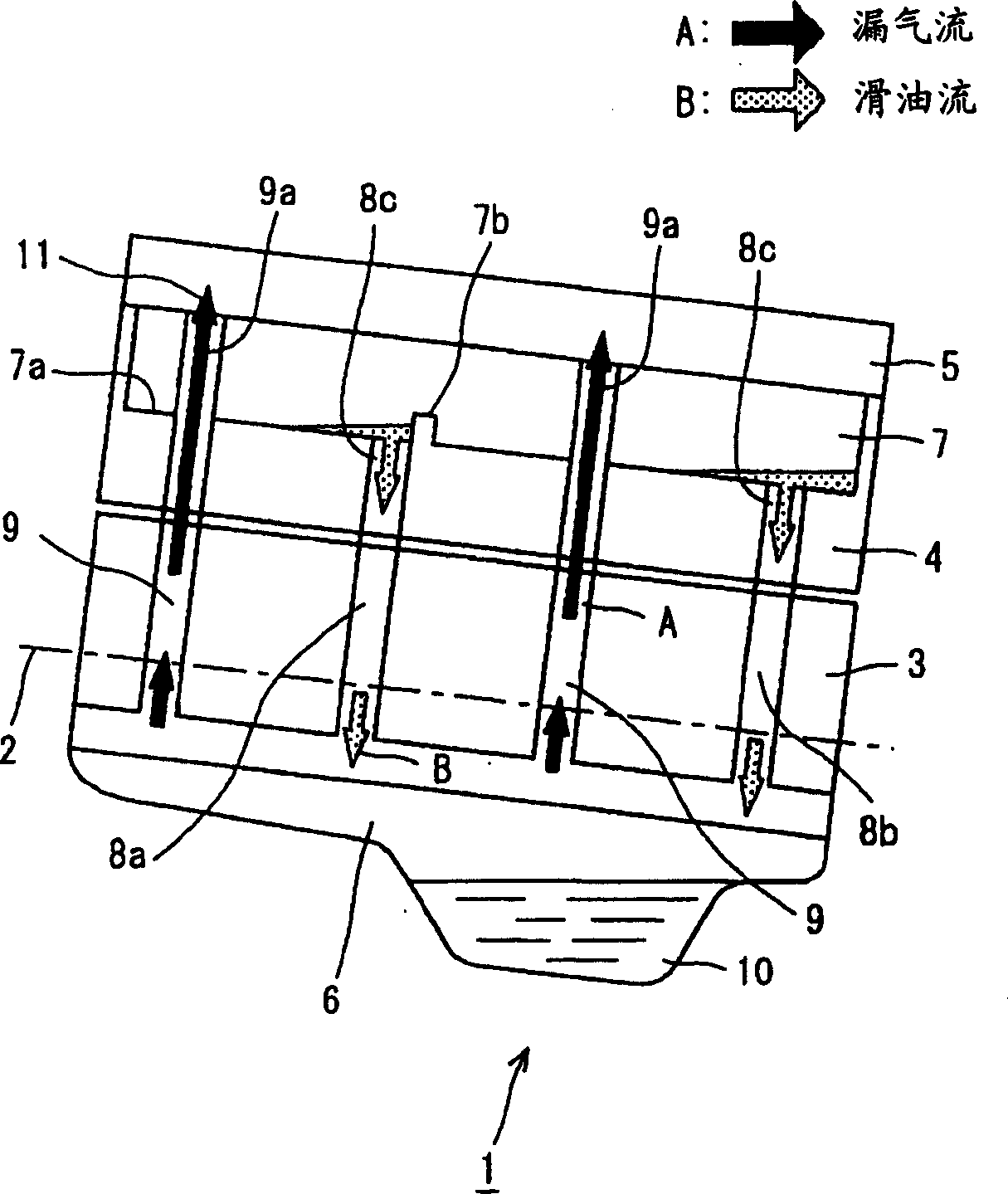

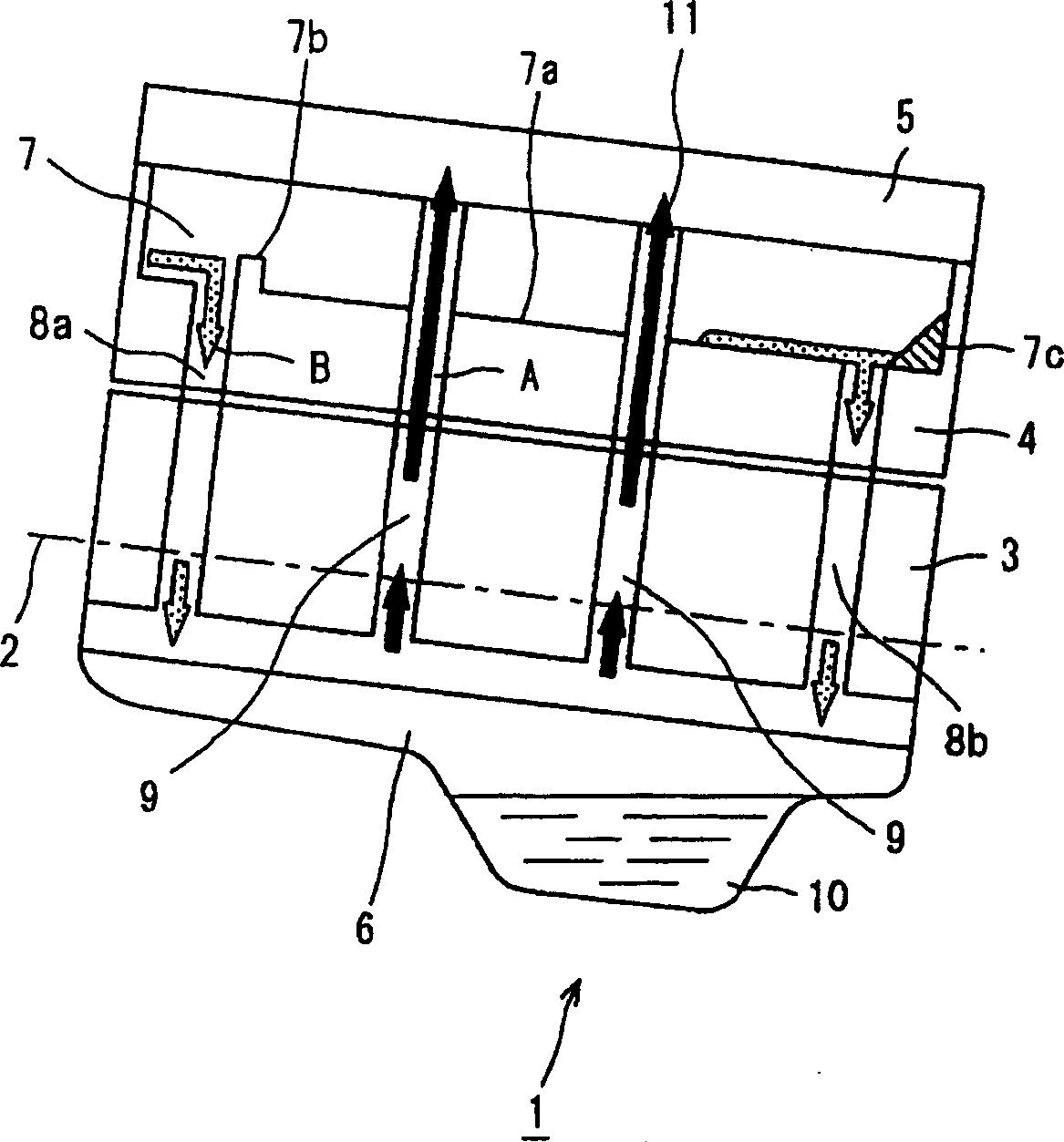

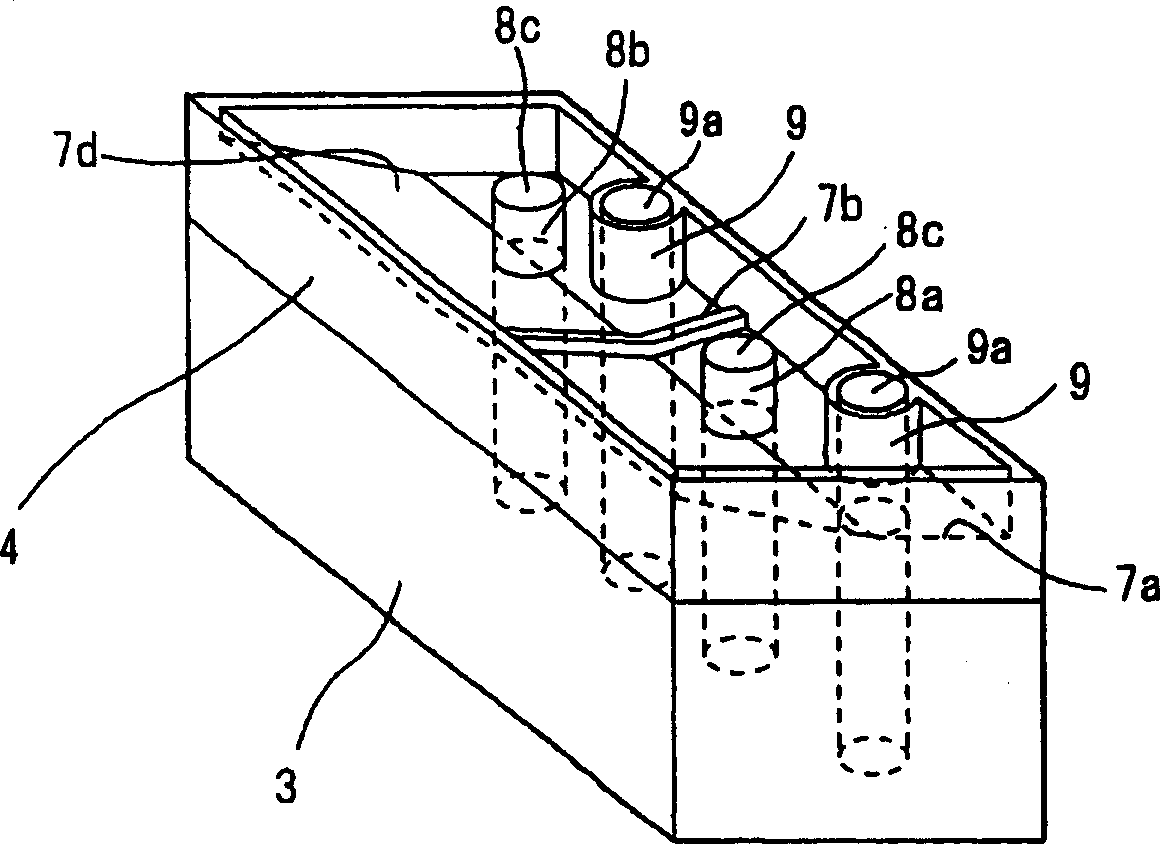

[0029] figure 1 A schematic diagram of an engine having a cylinder head structure according to an embodiment of the present invention is shown. image 3 A perspective view of an engine having a cylinder head structure of an embodiment of the present invention is shown.

[0030] The engine 1 is tilted in the direction of the crankshaft 2 (eg figure 1 As shown in , engine 1 is tilted down to the right). The oil collecting passages 8a and 8b and the blow-by air passage 9 are respectively arranged on the left or right side of the crankshaft 2 in the bottom surface portion 7a of the rocker chamber.

[0031] The engine 1 comprises a cylinder block 3 having cylinders in which pistons are slidably received, and a cylinder head 4 provided with a valve mechanism (not shown) for driving the suction Gas valve and exhaust valve. A cylinder head 4 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com