Label, Its ue and affixing method and appts.

A sticking device and labeling technology, which is applied to labels, identification devices, manual label dispensers, etc., can solve the problems of equipment cost reduction and surplus, and achieve the effects of inhibiting recrystallization, saving resources, and maintaining adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

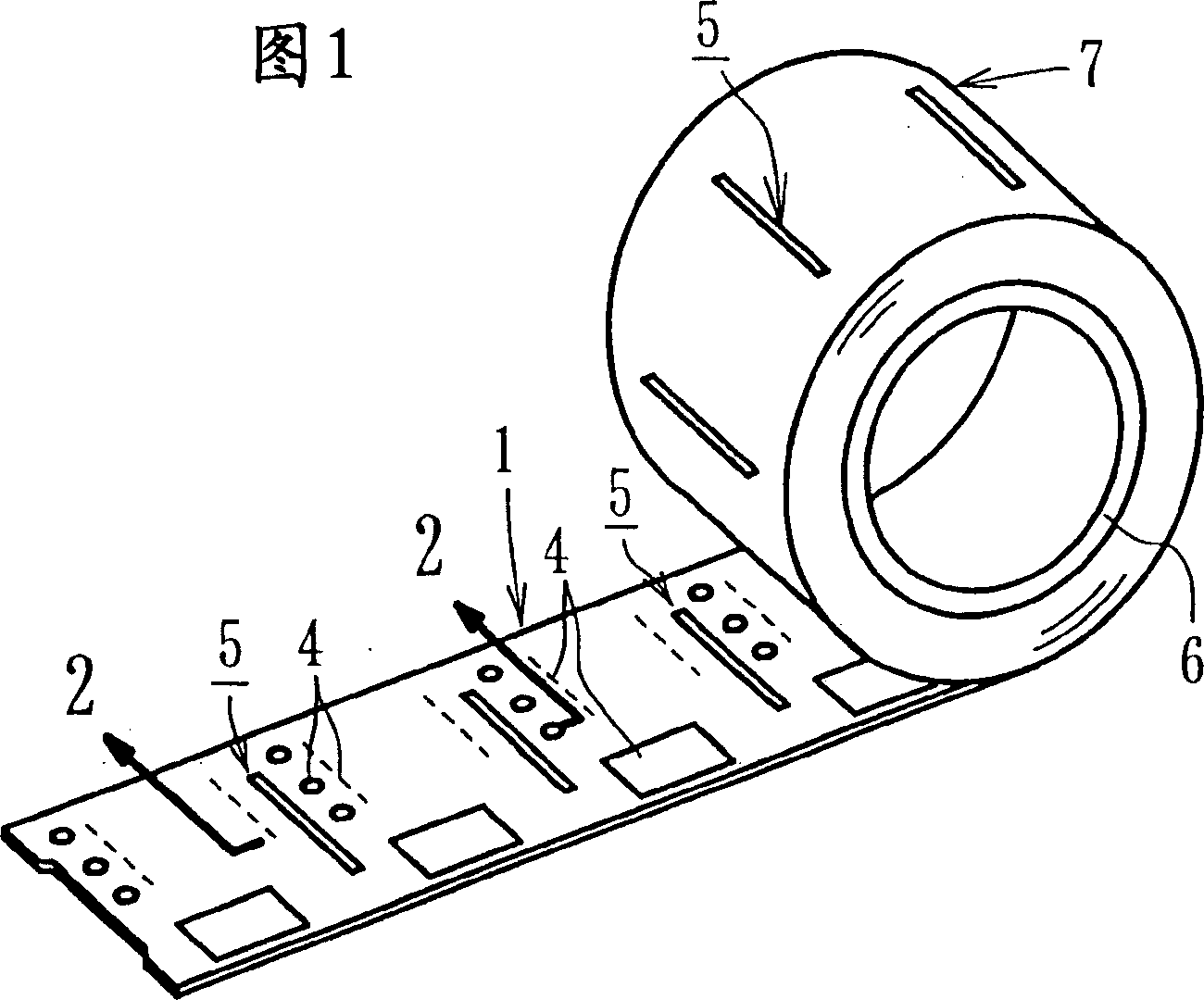

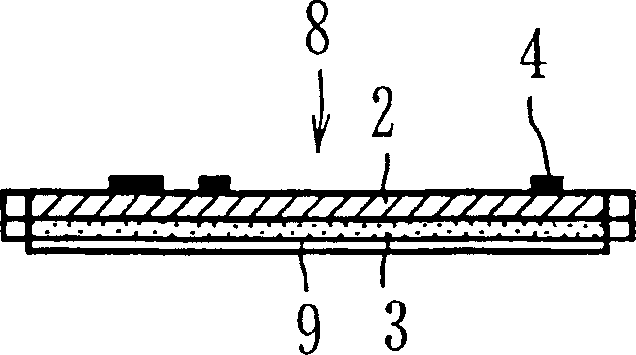

[0058] The following according to Figure 1 to image 3 A first embodiment of the present invention will be described.

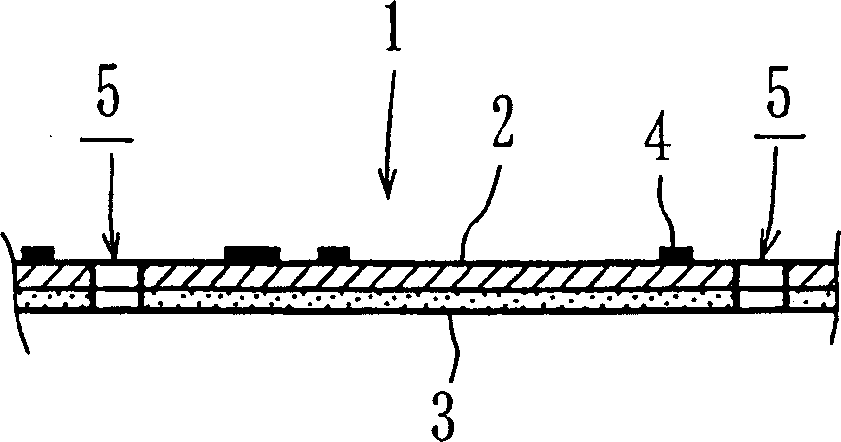

[0059] Figure 1 and image 3 As shown, the long strip-shaped label tape 1 of the present embodiment is that a plurality of label indications 4 are continuously printed on the surface to form a long strip-shaped paper label backing material 2 coated with a special adhesive 3 ( refer to figure 2 ).

[0060] Adhesive 3 is non-adhesive at room temperature, and can be bonded after heating to recover the adhesiveness. Therefore, for example, an adhesive such as EN900 of Dainippon Ink Co., Ltd. can be used.

[0061] The label representation 4 can be printed on the paper of the label base material 2 by various printing methods, and is printed continuously and sequentially.

[0062] On the label tape 1, the label representation 4 formed by the necessary and specified items of a plurality of continuous printed labels, the adjacent label representation 4, 4 in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com