Train tail unit locking hook

A technology of locking hook and column tail device is applied in the field of locking hook, which can solve the problems of inconvenient loading and unloading, rusting and greasy death of the transmission part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

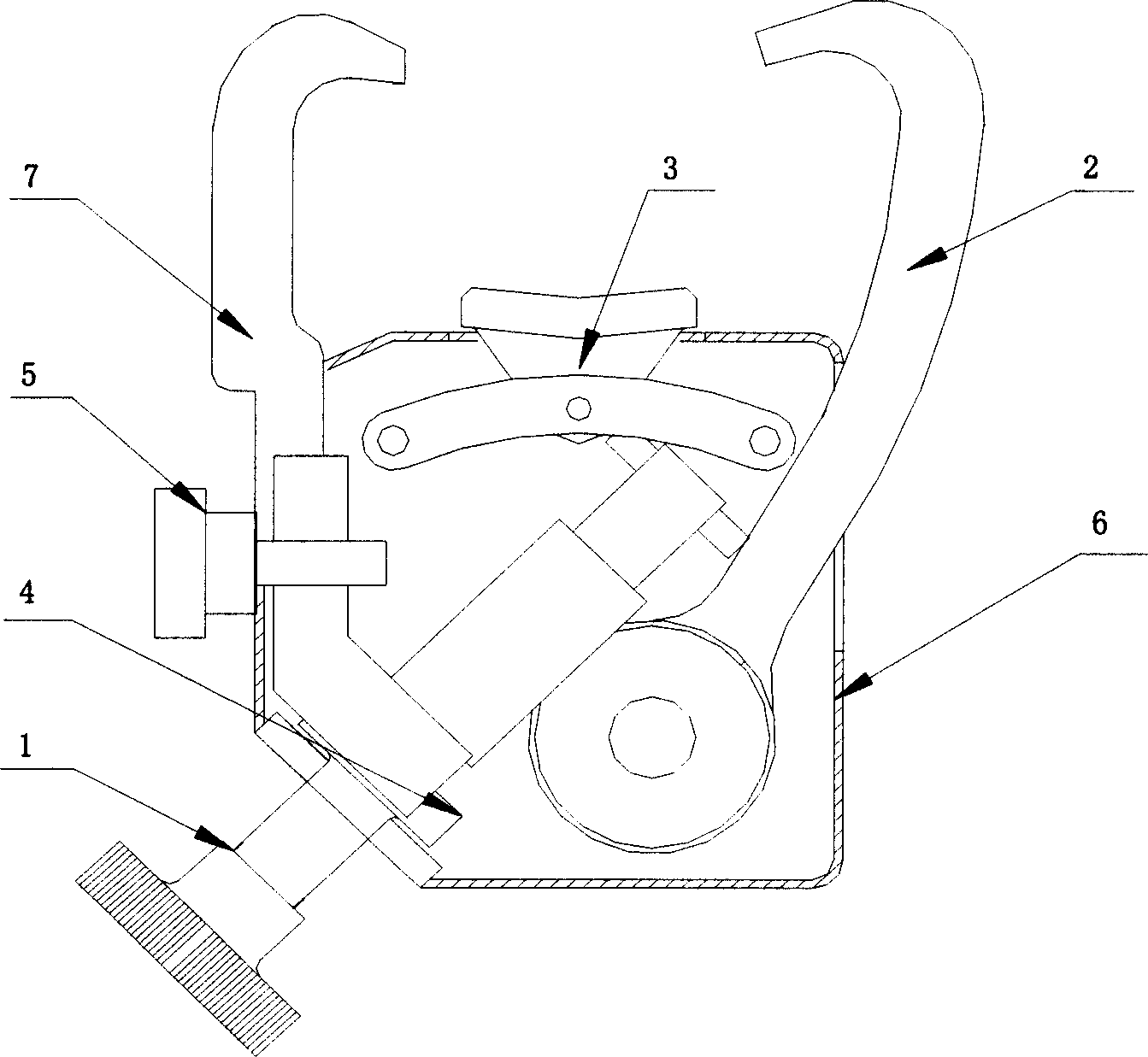

[0016] figure 1 It is a structural schematic diagram of an embodiment of the locking hook of the tail device of the present invention, which will be described in detail below in conjunction with the accompanying drawing. The locking hook mainly includes a transmission part, a clamping part and a housing 6 , wherein the transmission part is packaged in the housing 6 . The transmission part mainly uses the transmission characteristics of the worm gear-worm, which includes a worm 1 with a hand wheel and a worm wheel. The worm wheel and a hook are combined to form a worm gear hook 2. When the worm 1 rotates, The worm gear hook 2 is opened. When the worm 1 rotates clockwise to bring the worm gear hook 2 to the clamping position, if the worm 1 continues to rotate, while driving the worm gear hook to continue clamping, the front end of the worm 1 pushes the front top with the characteristics of a lever and a cam. The block 3 changes the force direction along the fulcrum, so that fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com