Multiple upper protective-seam gas burst-preventing exploitation method used in the exploitation of coal seams

A technology with multiple protection and protective layers, applied in surface mining, earth-moving drilling, underground mining, etc., can solve problems such as affecting production efficiency and economic benefits, affecting mining speed, threatening safety, etc., achieving obvious technical advantages and promotion and application prospects , the effect of reducing the cost of gas drainage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

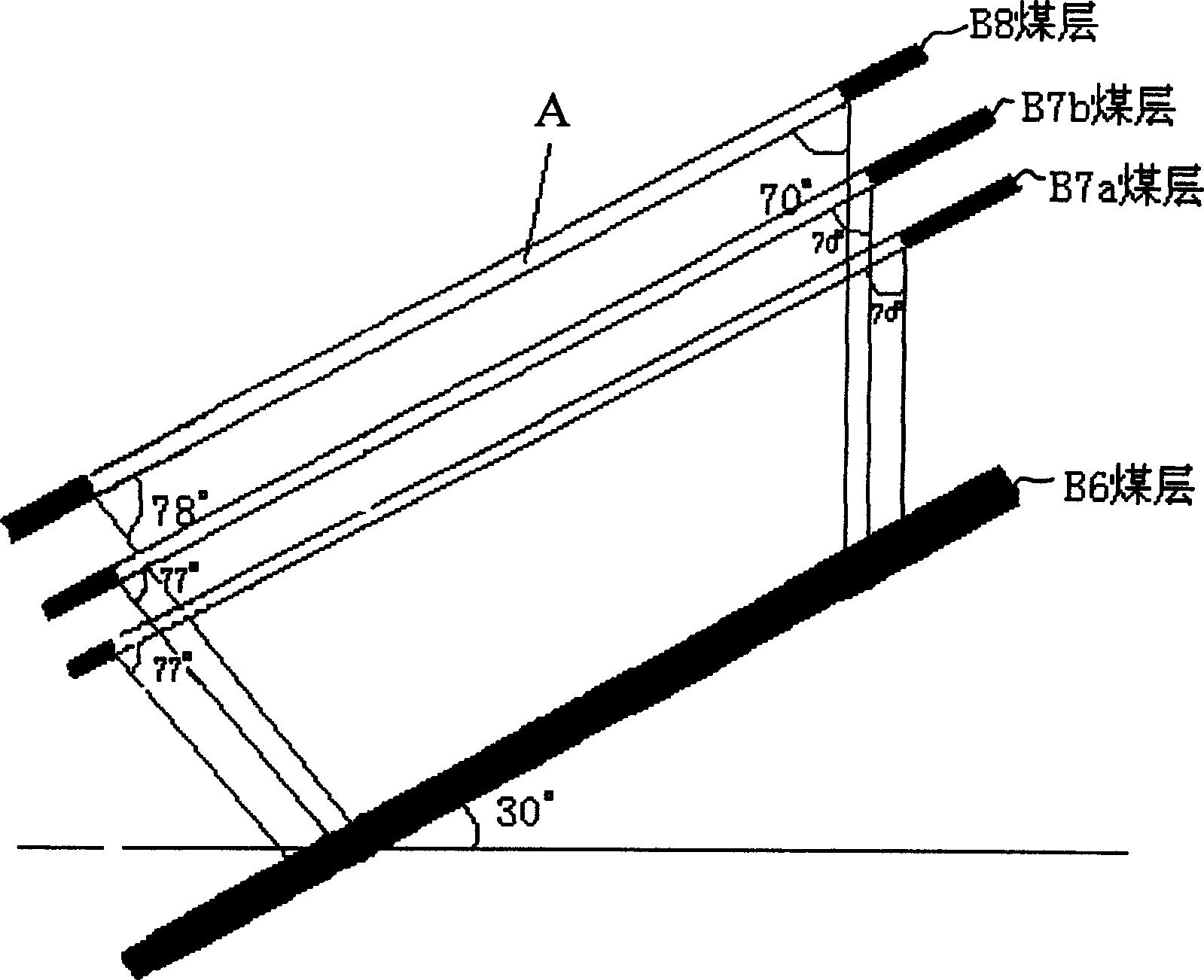

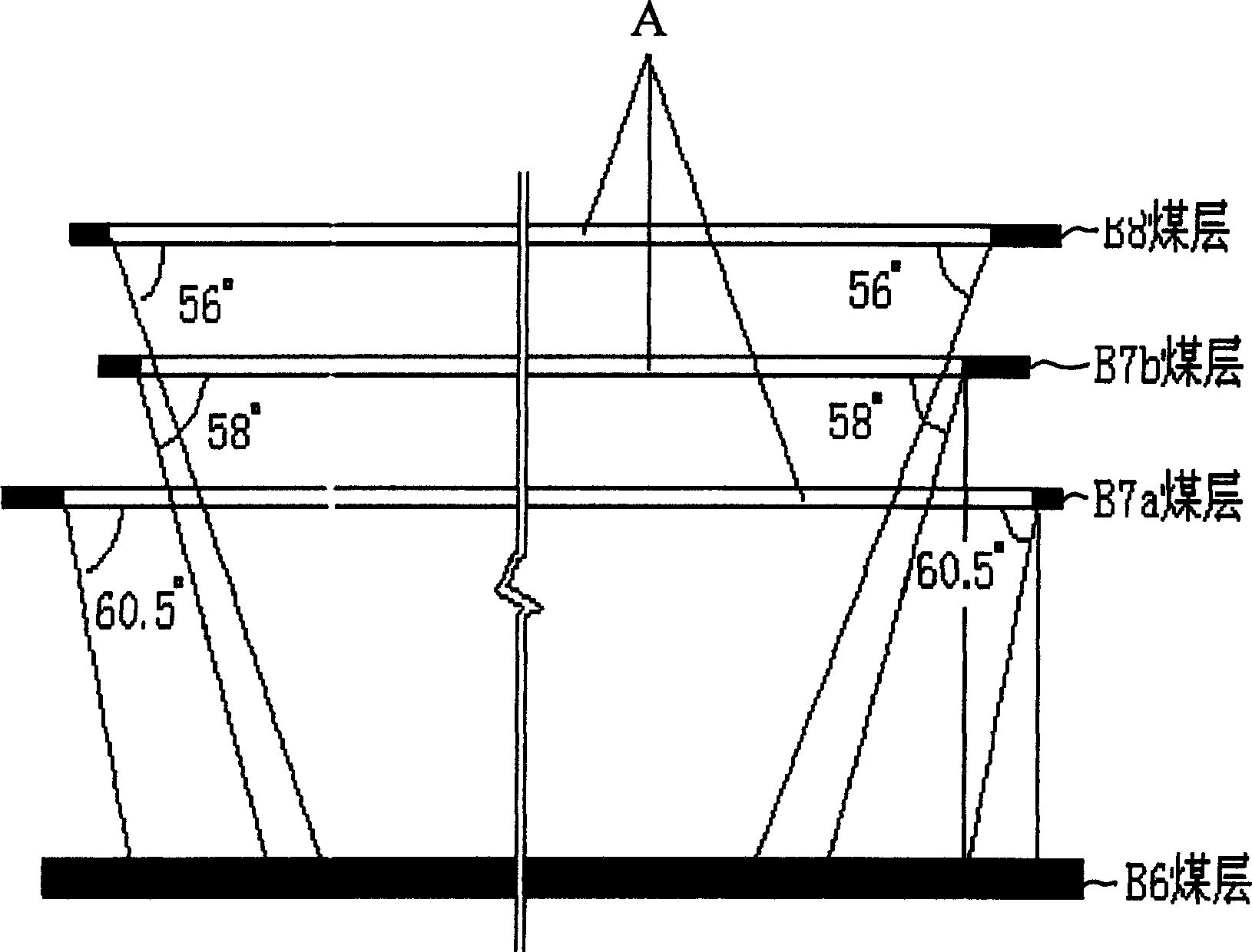

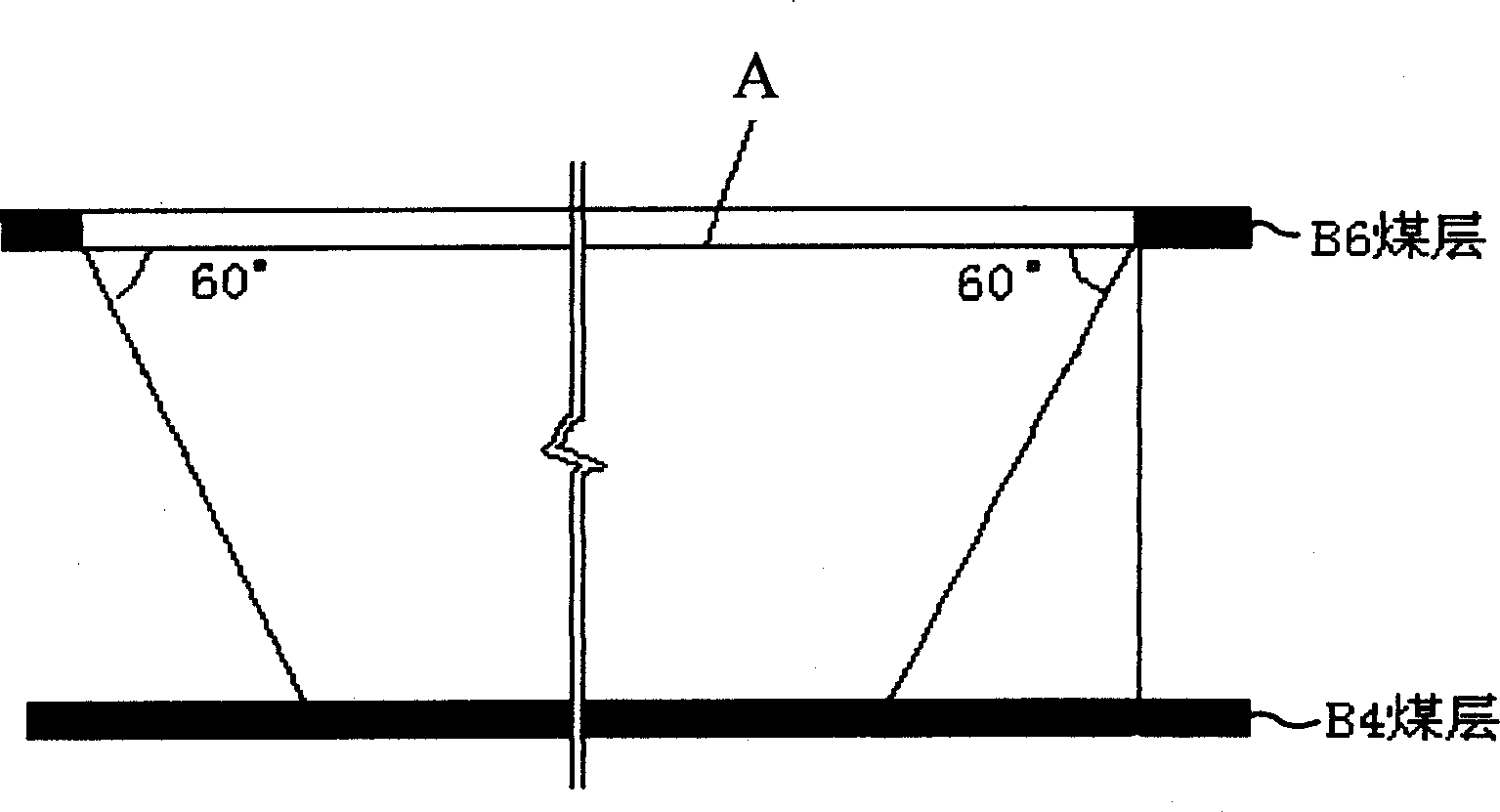

[0020] In coal seam group mining, the non-outburst coal seams B8 and B7 are selected as protective layers for mining first, then the protected outburst coal seam B6 is mined, and finally the protected outburst coal seam B4 is mined to form multiple protections for outburst coal seams ; While implementing multiple protective layer mining, combined with the pressure relief and enhanced drainage of the gas in the protected layer, the purpose of preventing coal and gas outburst in the protected layer is achieved, and the comprehensive management of gas in the protected layer is realized at the same time. The top-down mining method is adopted in the coal seam group, and the pressure relief effect of upper coal seam mining is used to improve the air permeability of the lower coal seam, and the bottom rock roadway is used to drill upward or downward through the coal seam to strengthen the gas drainage of the lower coal seam . Create conditions for efficient and intensive mining of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com