Continuous pressure-relief deslagging method and system of liquid-state pressure-boosting deslagging gasifier

A technology for pressurized gasification and liquid slag discharge, applied in the field of coal gasification, can solve the problems of high investment and operation cost of the lock hopper slag discharge system, complicated process of the lock hopper system, complicated operation and control system, etc. The effect of cycle stable operation, improved stability and reliability, simple operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained below in conjunction with the drawings:

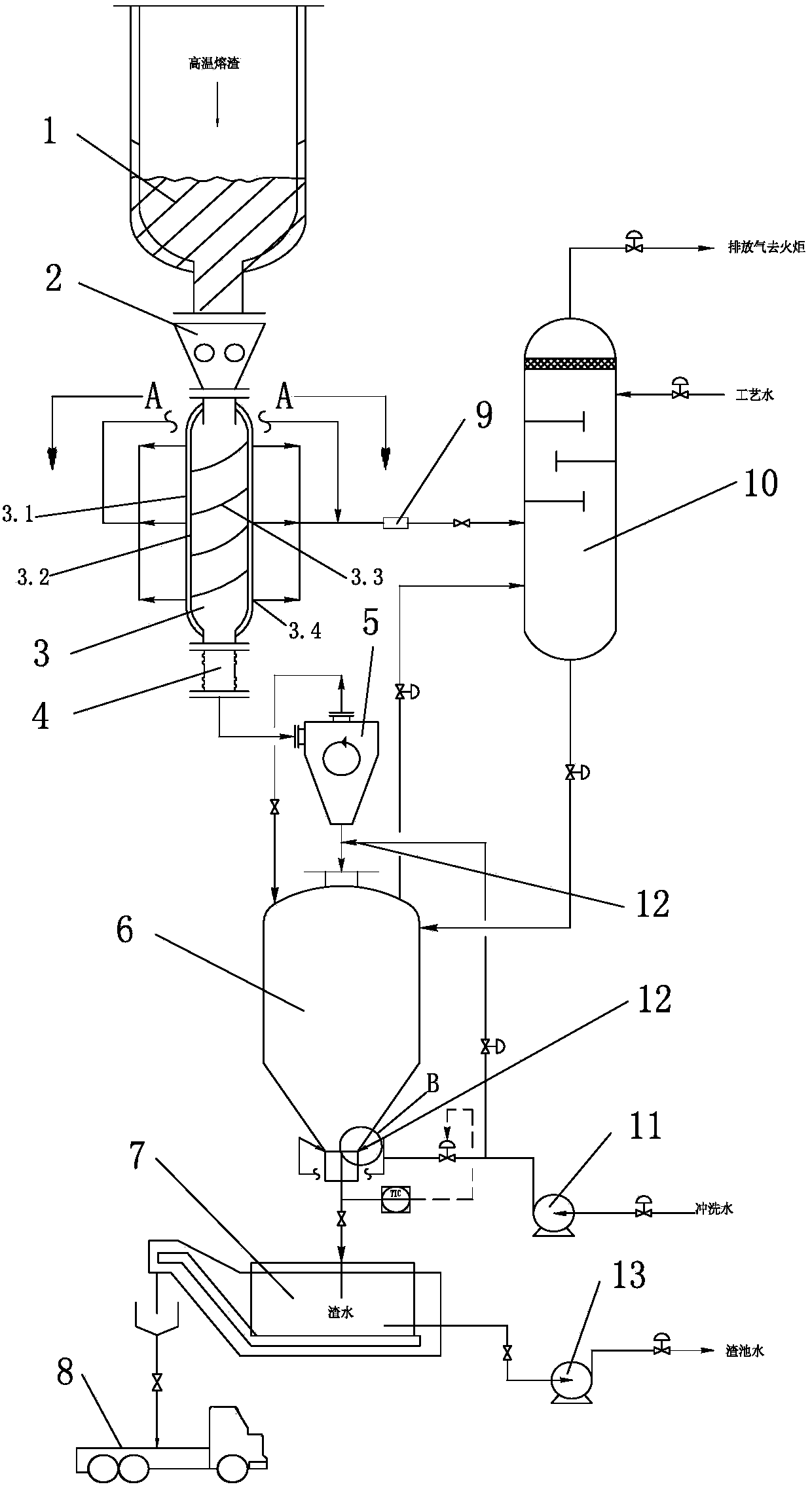

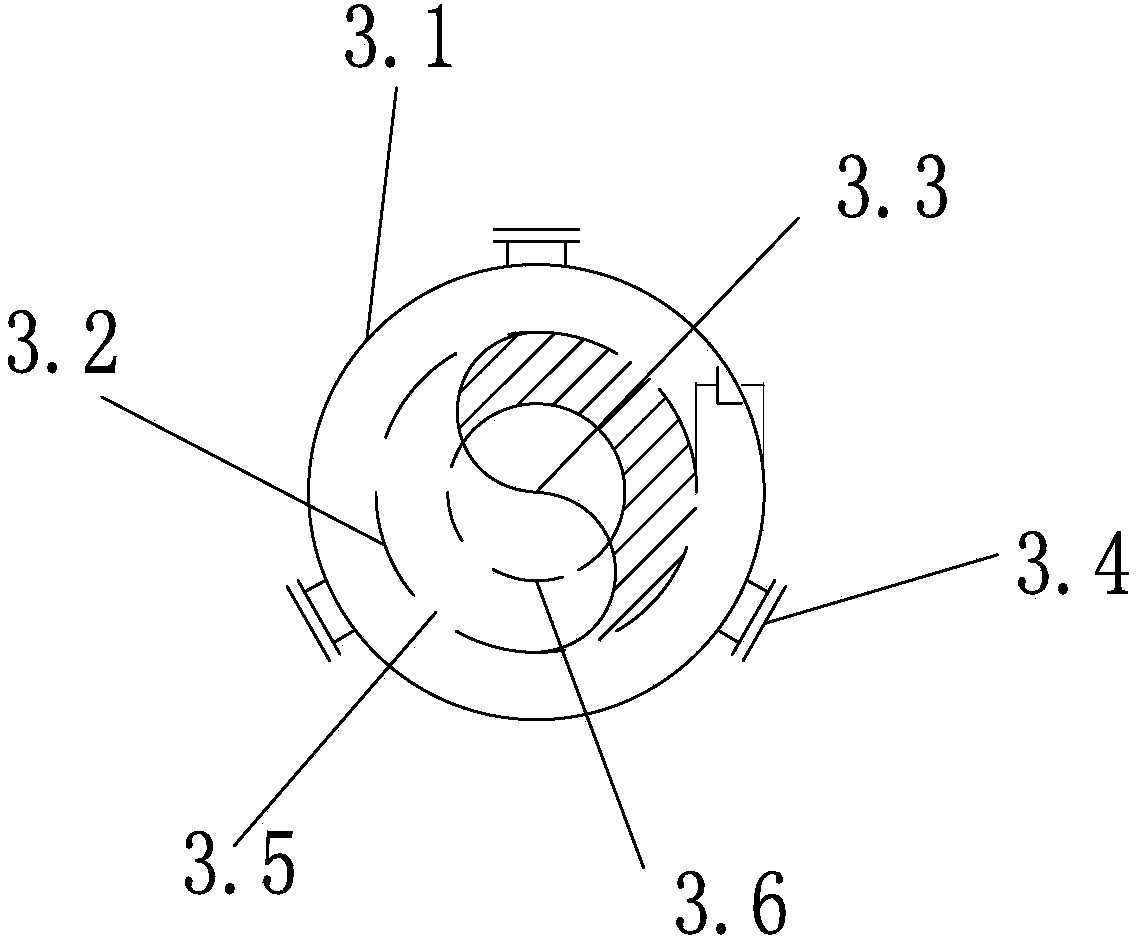

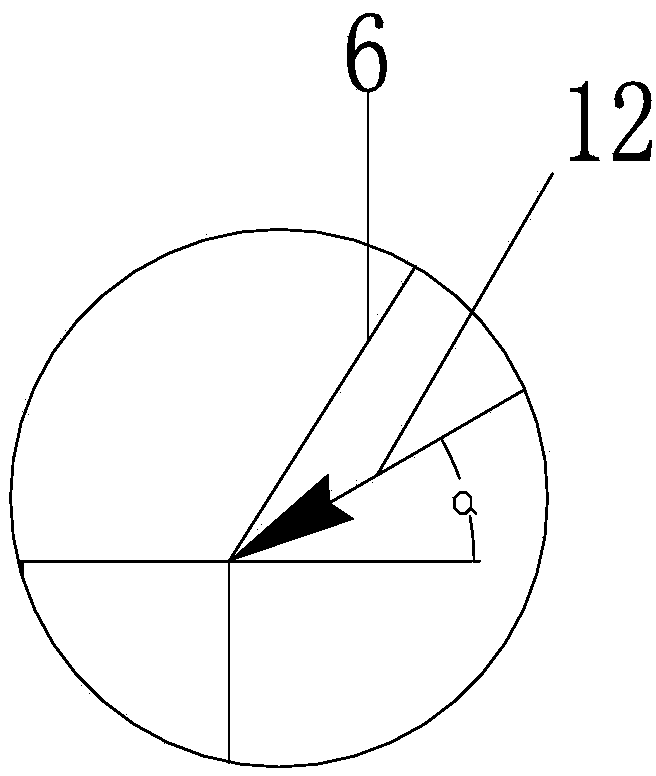

[0042] Refer to figure 1 , The slag water outlet of the pressurized gasifier 1 is sequentially connected with the slag breaker 2, the pressure reducing pipe 3, the expansion joint 4, the hydrocyclone 5, the slag collecting tank 6 and the slag conveyor 7. The pressure reducing pipe 3 It is also connected to the exhaust tank 10 via the throttling device 9, and the bottom outlet of the exhaust tank 10 and the top outlet of the hydrocyclone are also connected to the slag collection tank 6. The bottom outlet of the hydrocyclone 5 and the bottom outlet of the slag collecting tank 6 are both provided with a flushing pipe 12, and the flushing pipe 12 is connected to the gray water pump 11 through a pipe. The non-condensable gas outlet of the slag collecting tank 6 is also connected to the exhaust tank 10, and the downward inclination angle a of the flushing pipe 12 at the bottom of the slag c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com