Heat accumulation type horse hoof flame glass pool oven with modified pool and its uses

An improved, regenerative technology, used in glass furnace equipment, retort furnaces, glass production, etc., can solve the problems of low heat exchange efficiency of horseshoe flame furnaces, unreasonable longitudinal flame distribution, and reduced glass melting quality. To achieve the effect of simple structure, good melting quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and have example to make further description:

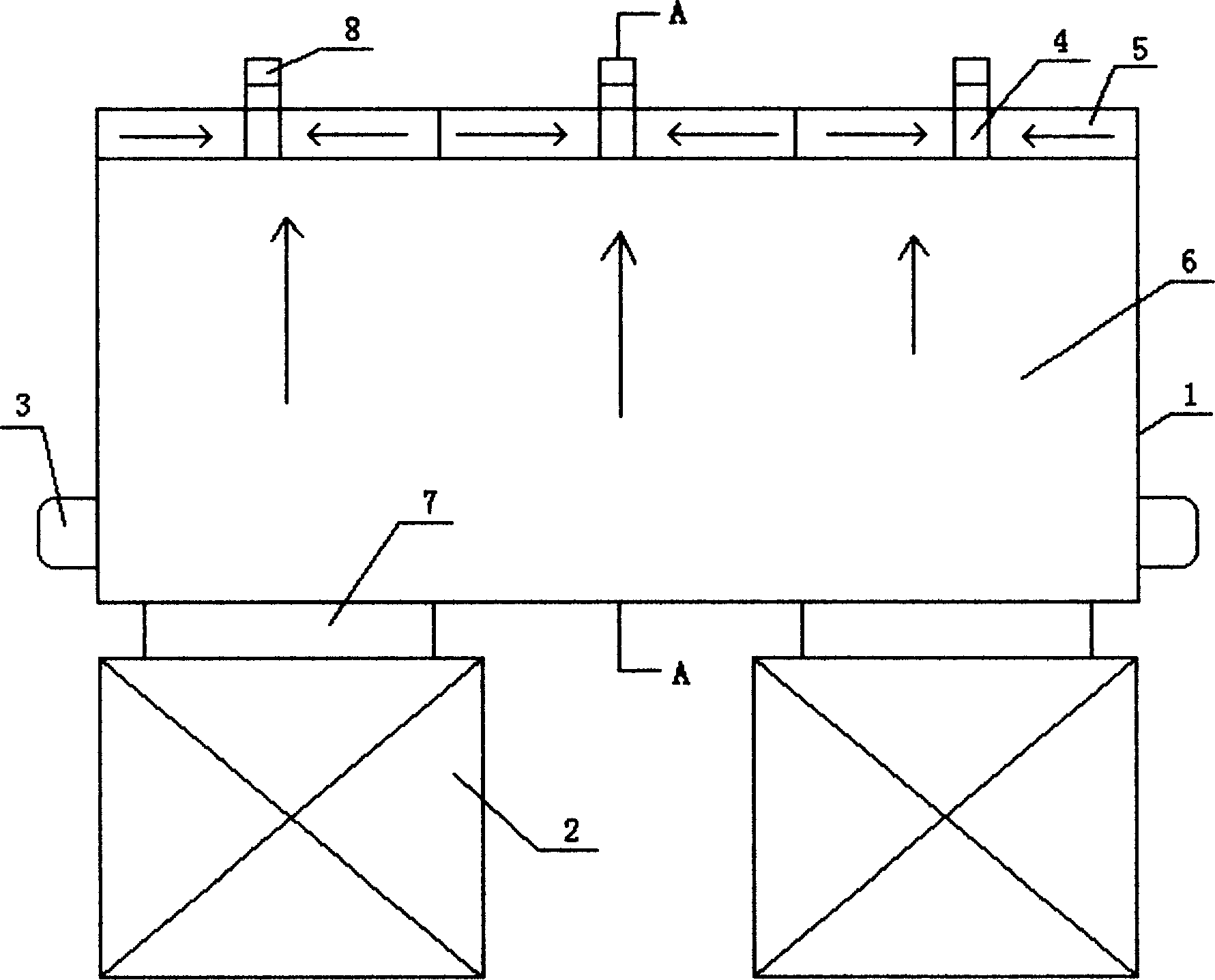

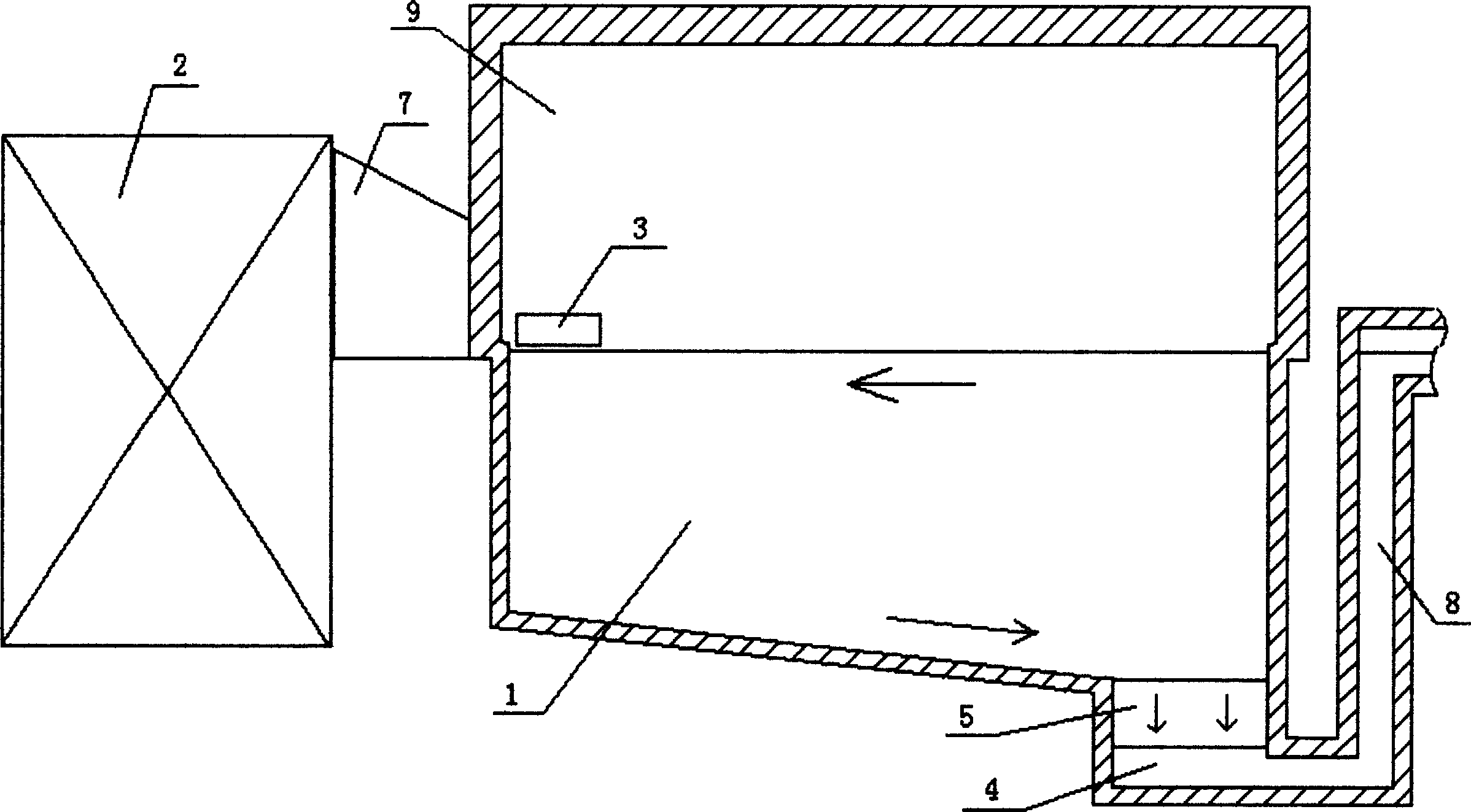

[0021] The pool-shaped improved regenerative horseshoe flame glass pool furnace of the present invention comprises a melting pool 1 with a dome, a regenerator 2, a feeding port 3 and a liquid flow hole 4, and the shape of the melting pool 1 is vertically short and horizontally long Extended type. The longitudinal length of the melting pool 1 is 9 meters, and the lateral width of the melting pool 1 is 16 meters. The front end of the bottom of the melting pool 1 is formed with a transverse diversion groove 5 that inclines toward the flow hole 4 , and the bottom of the melting pool 1 is formed with a longitudinal diversion slope 6 that inclines toward the flow groove 5 . The gradient of the diversion slope 6 is 3%, and the gradient of the diversion groove 5 is 0.5%, which is the ratio of the height of the slope to the horizontal length of the slope. The distance from the highes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com