Method for testing power type LED thermal resistance and special purpose chip thereof

A technology of LED chips and special chips, which is applied in the field of accurate measurement of thermal resistance characteristics of power LED devices, can solve the problems of complicated operation, reduced R&D cost, high price, etc., so as to reduce manufacturing cost, reduce testing cost, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below.

[0023] The test method includes the following steps:

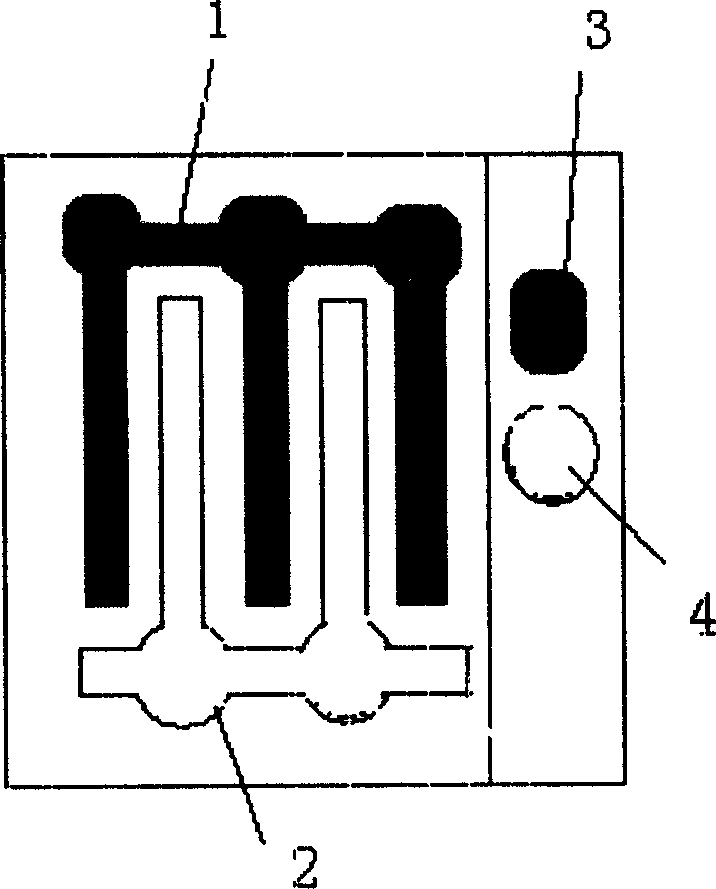

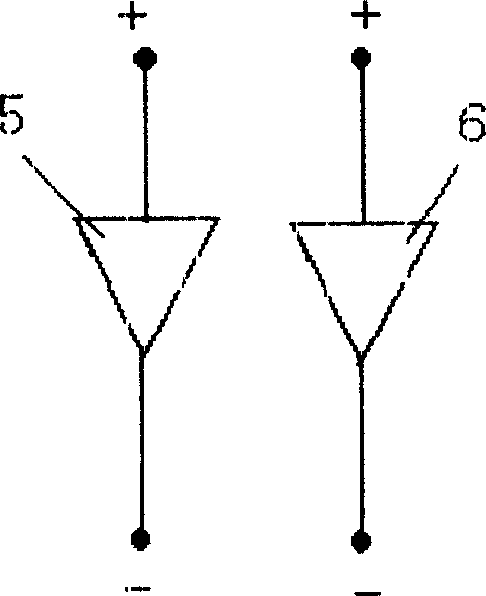

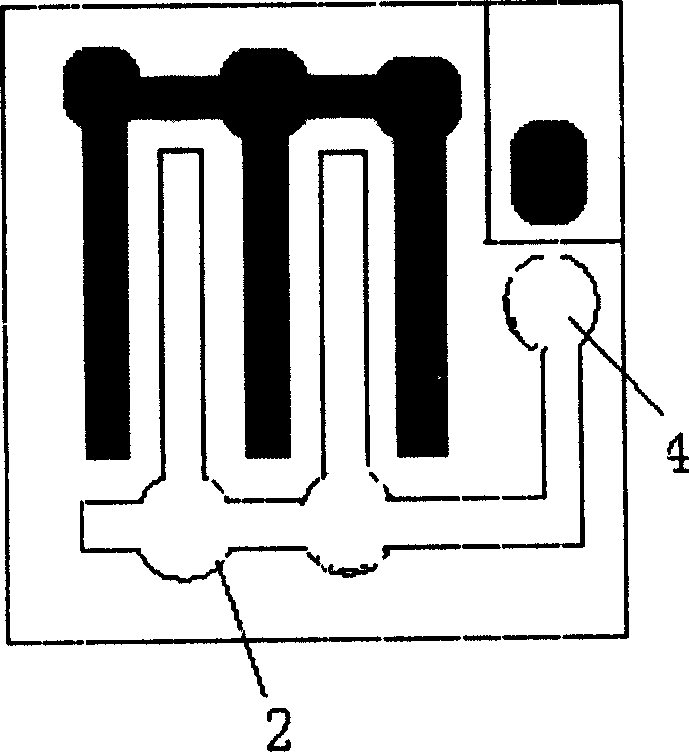

[0024] a. Manufacture a dedicated chip and integrate two LED units in the chip. The epitaxial layer and electrode layer structure of the two units are the same as the designed power LED chip, that is, the material composition, structure, and thickness of each layer are the same. It is the same as the designed power LED chip, and if the designed power LED chip has various auxiliary layers, then the dedicated chip also adds corresponding auxiliary layers. One of the two LED units is a heating unit, and the area of this unit should be as close as possible to the area of the designed power LED chip, in order to enable the unit to withstand higher current and to simulate as accurately as possible Heat generation of the designed power LED. The other LED unit is a detection unit. The area of this unit should be as small as possible, preferably no mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com