Method for fabricating heating element and electrode lead in carbon fiber far infrared electric heating tube

A carbon fiber far-infrared, heating element technology, applied in the direction of heating element material, heating element shape, ohmic resistance heating parts, etc., can solve the problems of easy burnout of contacts, difficult to guarantee life, difficult to control power, etc., to ensure uniform heating performance, expanding the scope of application, and ensuring the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The steps of the present invention will be described in further detail below in conjunction with the accompanying drawings.

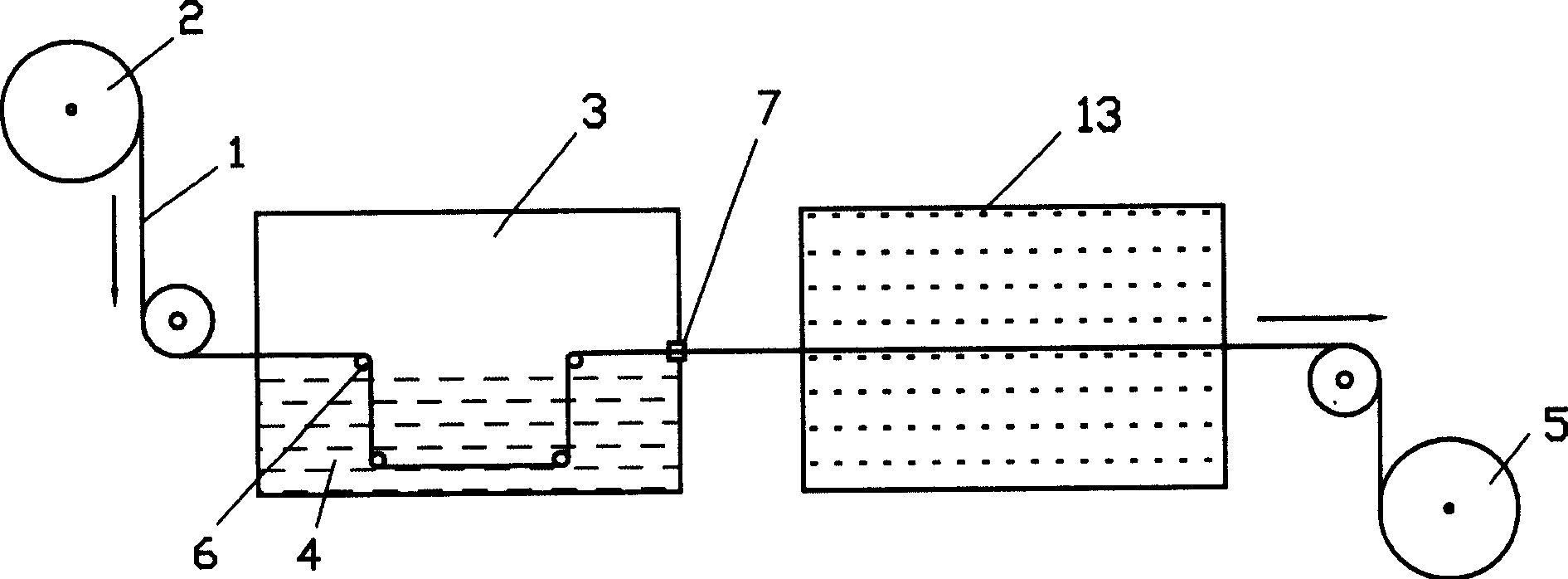

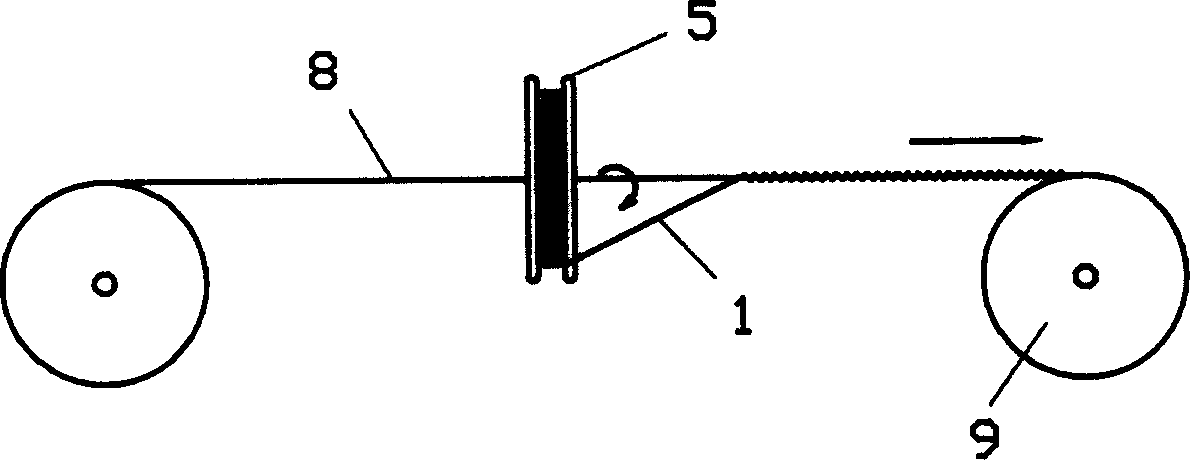

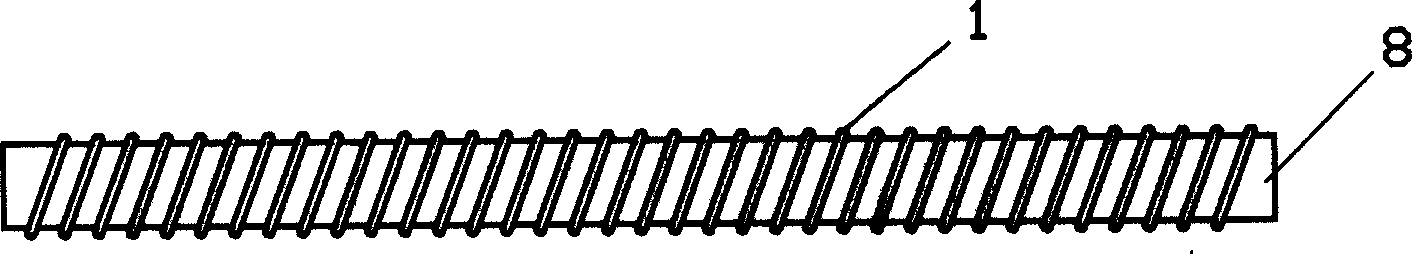

[0016] a. Coating water-soluble resin melamine formaldehyde on the carbon fiber bundle formed by gathering carbon fiber monofilaments. The carbon fiber bundle formed by gathering a plurality of carbon fiber monofilaments in this step can be purchased directly from the market, and generally thousands of them form a bundle. If the count of the purchased carbon fiber bundles is not enough, you can also gather the purchased carbon fiber bundles into one bundle. The water-soluble resin melamine formaldehyde acts as a bond protection to prevent the carbon fiber bundles from breaking or fluffing during subsequent processing. In order to facilitate the coating of melamine formaldehyde, it can be as figure 1 As shown, the carbon fiber bundle 1 is first wound on the shaft 2 of the winding device through a speed-regulating motor, and then the carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com