Motor with a brake

A technology of brakes and motors, applied in the field of motors, can solve problems such as overloading of the motor itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the motor with brake according to the present invention will be described below with reference to the drawings.

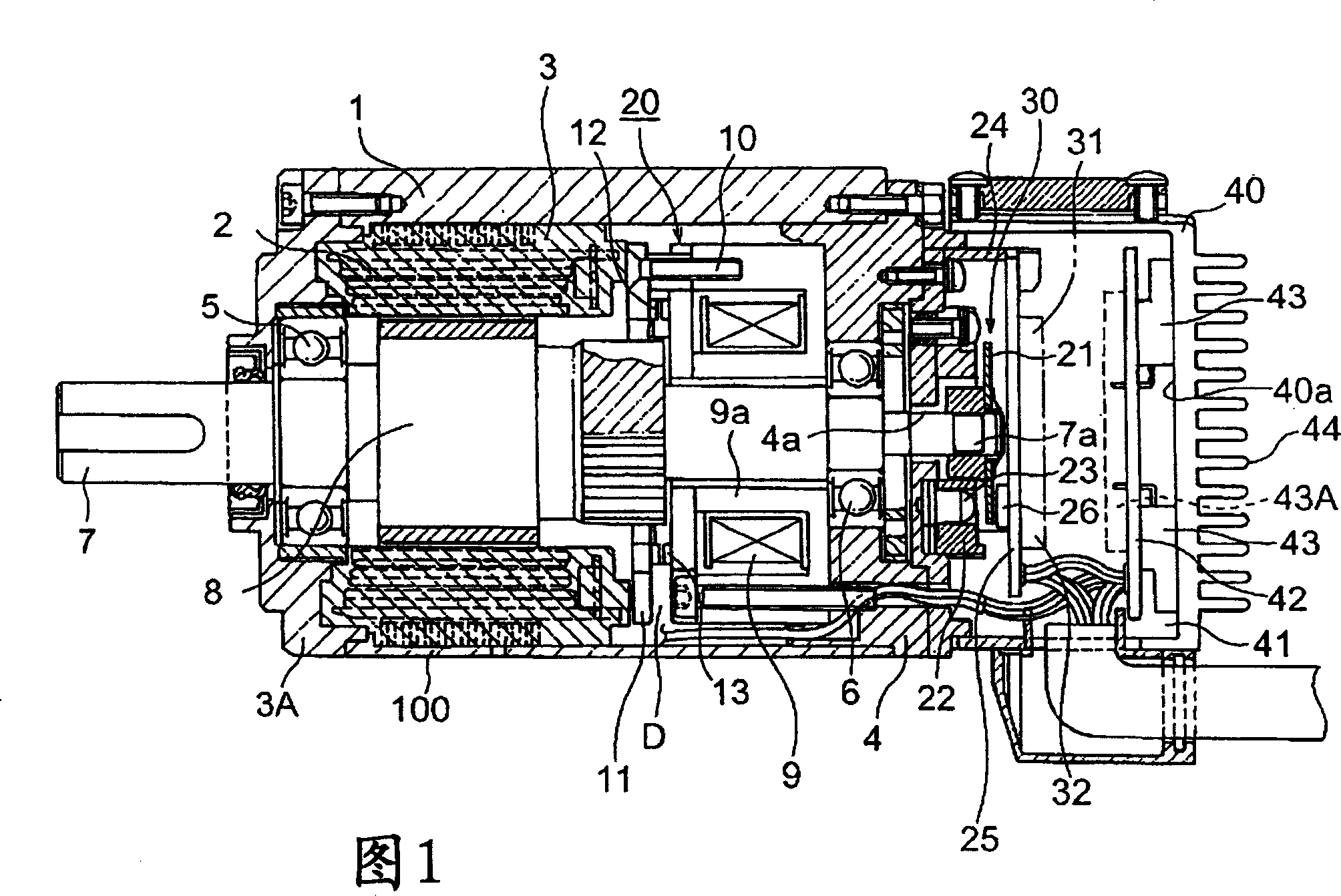

[0020] Reference numeral 1 in FIG. 1 is a cylindrical casing with a stator 3 around which a stator coil 2 is wound. A front cover 3A and a rear cover 4 are installed at both ends of the cylindrical casing 1 .

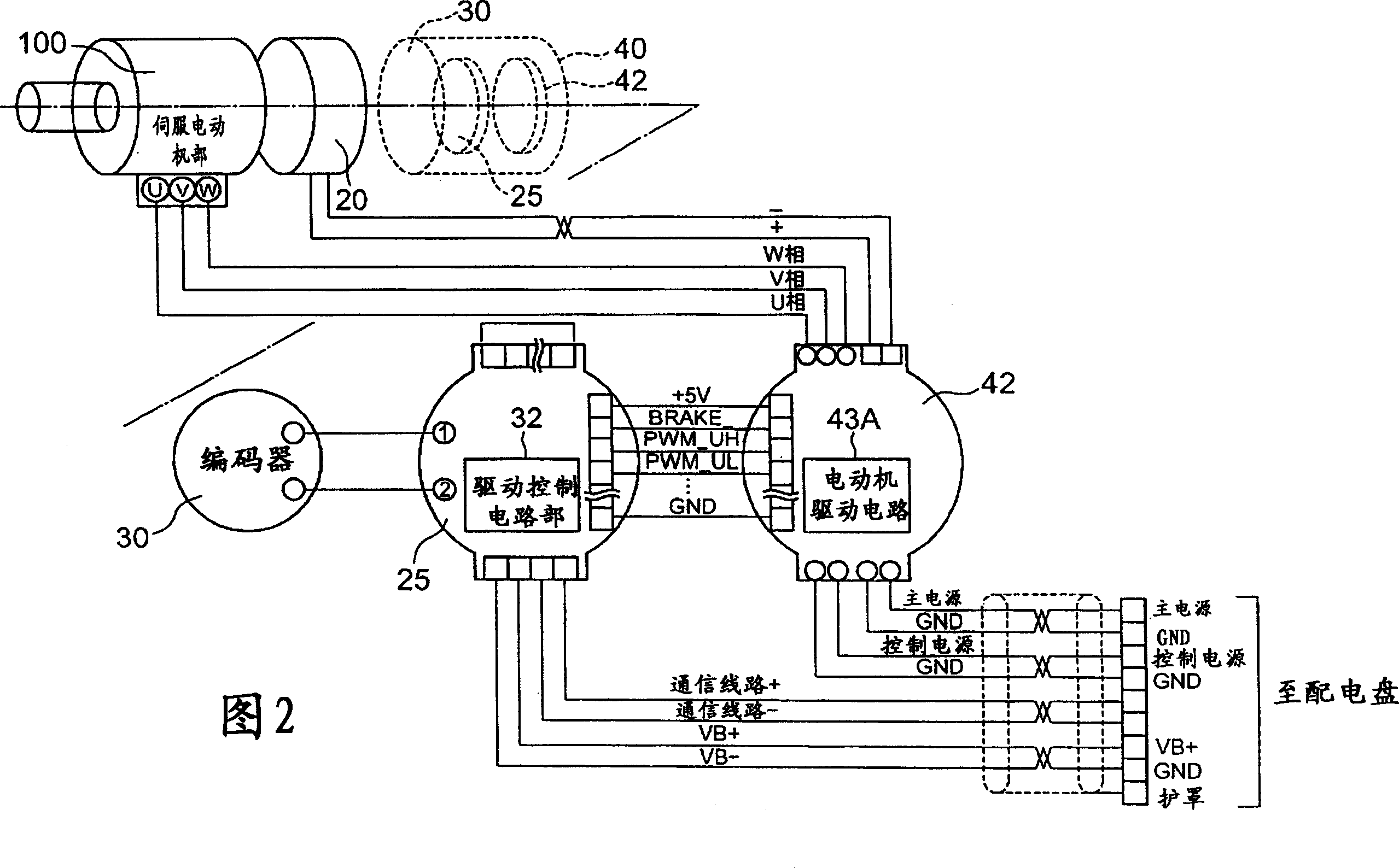

[0021] Each bearing 5,6 is mounted on the front cover 3A and the rear cover 4, the rotating shaft 7 is freely rotatably mounted on each bearing 5,6, and the rotor 8 located inside the stator 3 is freely rotatably mounted on the rotating shaft 7, An electromagnetic driving part 9 with an excitation coil (not shown in the figure) is installed on the back cover 4 . The stator 3 , the rotor 8 and the encoder 30 constitute a servo motor unit 100 .

[0022] At the position on the side of the front cover 3A of the electromagnetic driving part 9 , the fixing plate 11 is fixedly assembled on the electromagnetic driving part 9 with bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com