Polyvinyl chloride coating rain-coat cloth and its preparing method

A technology of polyvinyl chloride and polyvinyl chloride film, applied in textiles and papermaking, etc., can solve the problems of difficulty in meeting the needs of the PLA for flood fighting and emergency rescue, marching operations, poor strength of film raincoats, and bulky rubber raincoats, etc., and achieves excellent and good rainproof effect. Good peel strength and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

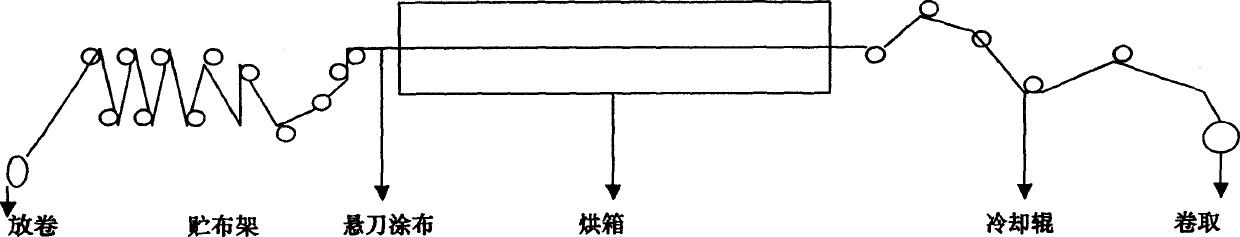

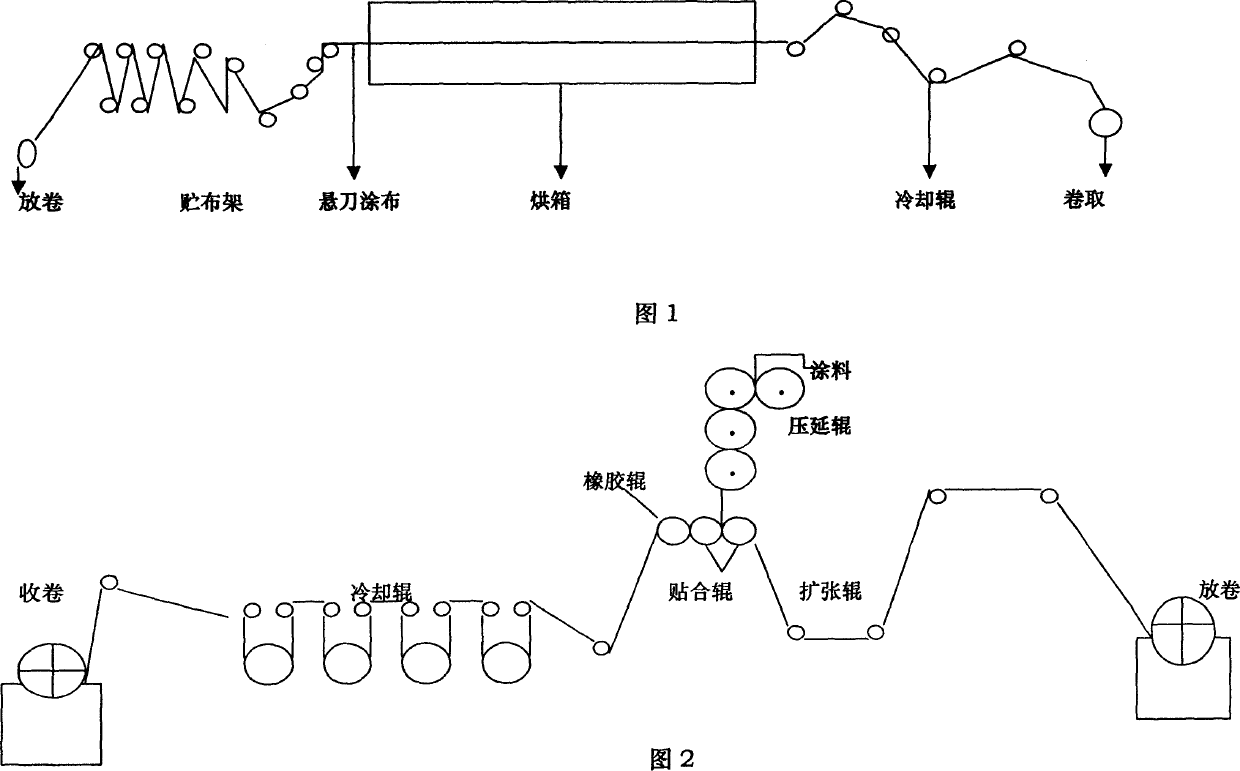

[0024] As shown in Figure 1 and Figure 4, coating the PU adhesive layer: first unwind the selected base cloth, and carry out hanging knife coating after passing through the cloth storage rack. The consumption of the adhesive material is 0.015kg / m, and the speed It is 30m / min, and it is dried after coating. The oven temperature is 110°C. After leaving the oven, it is cooled by a steel roller with cooling water circulation, and then wound. PU binder formula: 100 kilograms of two-component PU binder resin for PVC, 3 kilograms of dimethylformamide, 3 kilograms of toluene, and 4 kilograms of bridging agent.

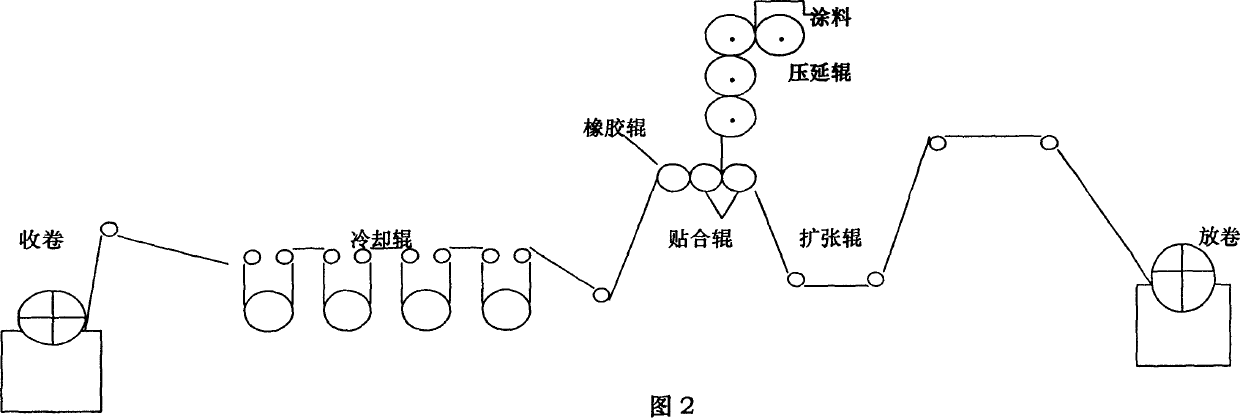

[0025] As shown in Figure 2 and Figure 5, PVC calendering film: first measure 100 kg of PVC-III type resin, 70 kg of DOP, 3 kg of dioctyl sebacate, 2 kg of Ba-Cd-Zn mixed stabilizer, CaCO 3 5 kg, appropriate amount of pigment, put into the kneader, stir evenly at a certain temperature, and initially plasticize. The kneading time is 8 minutes, and then banburying is carried ou...

Embodiment 2

[0027] Coating PU adhesive layer: Firstly, unwind the selected base cloth, pass through the cloth storage rack, and then carry out hanging knife coating. The binder consumption is 0.03kg / m, and the vehicle speed is 15m / min. Drying is carried out after coating, and the oven temperature is 150°C. After leaving the oven, it is cooled by steel rollers with cooling water circulation, and then rolled. The formula of the PU adhesive is: 100 kg of two-component PU adhesive resin for PVC, 8 kg of dimethylformamide, 15 kg of toluene, and 12 kg of bridging agent.

[0028] PVC calendering film: First measure 100 kg of PVC-III type resin, 90 kg of DOP, 15 kg of dioctyl sebacate, 4 kg of Ba-Cd-Zn mixed stabilizer, CaCO 3 15 kg, appropriate amount of pigment. Add it into the kneader, stir evenly at a certain temperature, and initially plasticize, and the kneading time is 12 minutes. Then banburying is carried out, and the color paste is added, and the set temperature is 160°C. After ban...

Embodiment 3

[0030] Coating PU adhesive layer: Firstly, unwind the selected base cloth, pass through the cloth storage rack, and then carry out hanging knife coating. The binder consumption is 0.02kg / m, and the vehicle speed is 20m / min. After coating, it is dried, the oven temperature is 130°C, after leaving the oven, it is cooled by a steel roller with cooling water circulation, and then rolled. The formula of the PU adhesive is: 100 kg of two-component PU adhesive resin for PVC, 5 kg of dimethylformamide, 10 kg of toluene, and 8 kg of bridging agent.

[0031] PVC calendering film: First measure 100 kg of PVC-III type resin, 80 kg of DOP, 10 kg of dioctyl sebacate, 3 kg of Ba-Cd-Zn mixed stabilizer, CaCO 3 10 kg, appropriate amount of pigment. Add it into the kneader, stir evenly at a certain temperature, and initially plasticize. The kneading time is 10 minutes, and then carry out banburying. The set temperature is 165°C. After banburying, carry out kneading for further plasticization....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com