Optical signal collecting and on-line monitoring method for electric power equipment internal failure

A technology for internal faults and electrical equipment, applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve problems such as inability to distinguish optical signals, misjudgment of discharge faults, errors, etc., to achieve easy promotion, reduce equipment damage, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

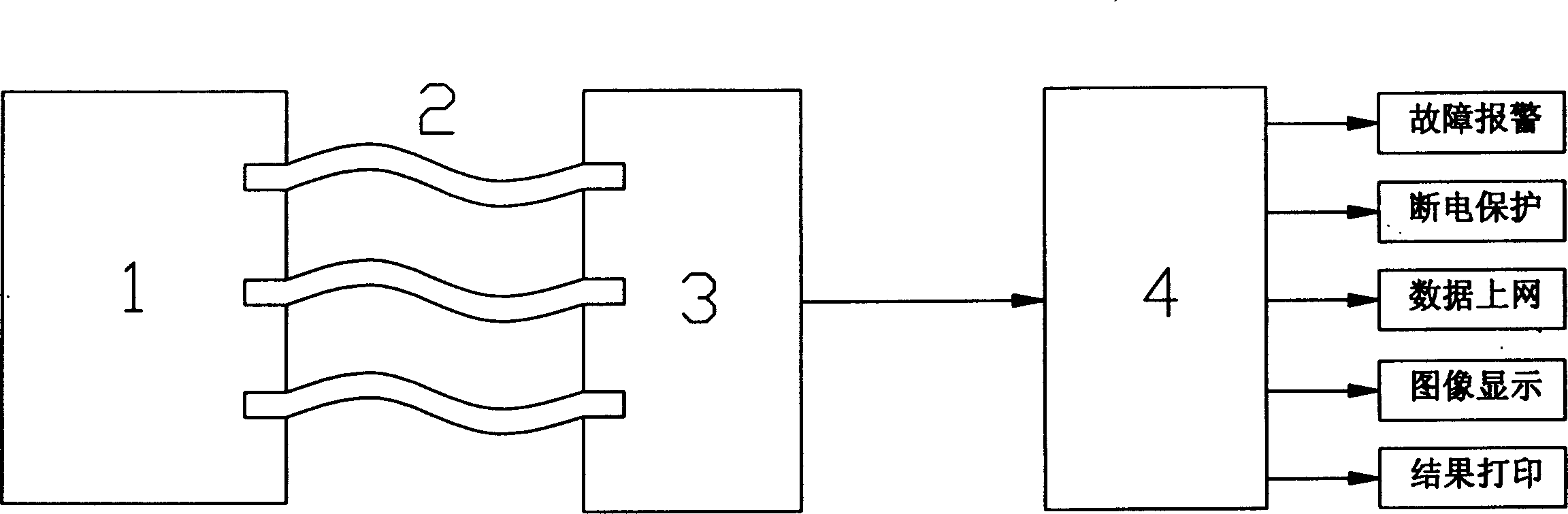

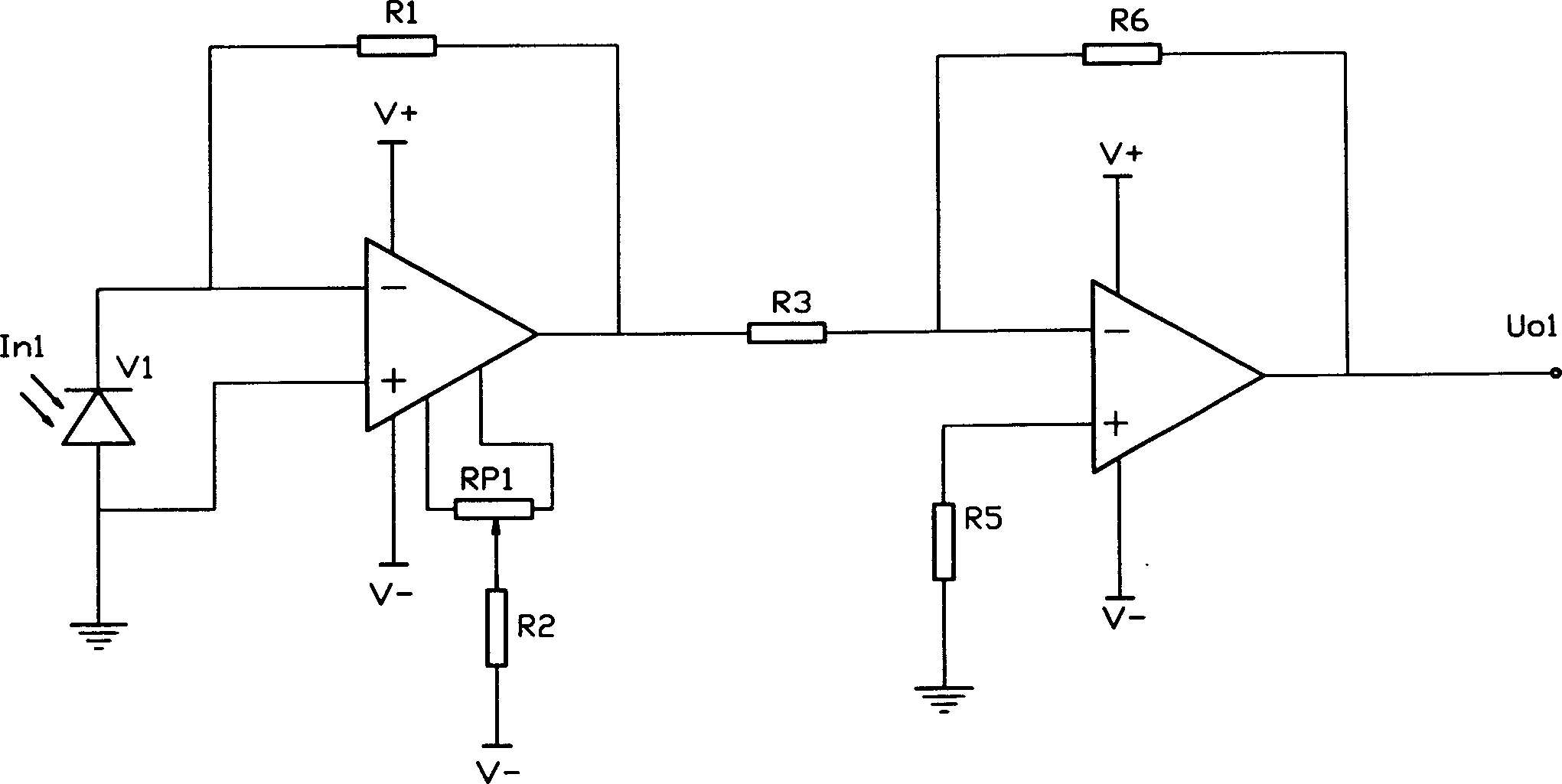

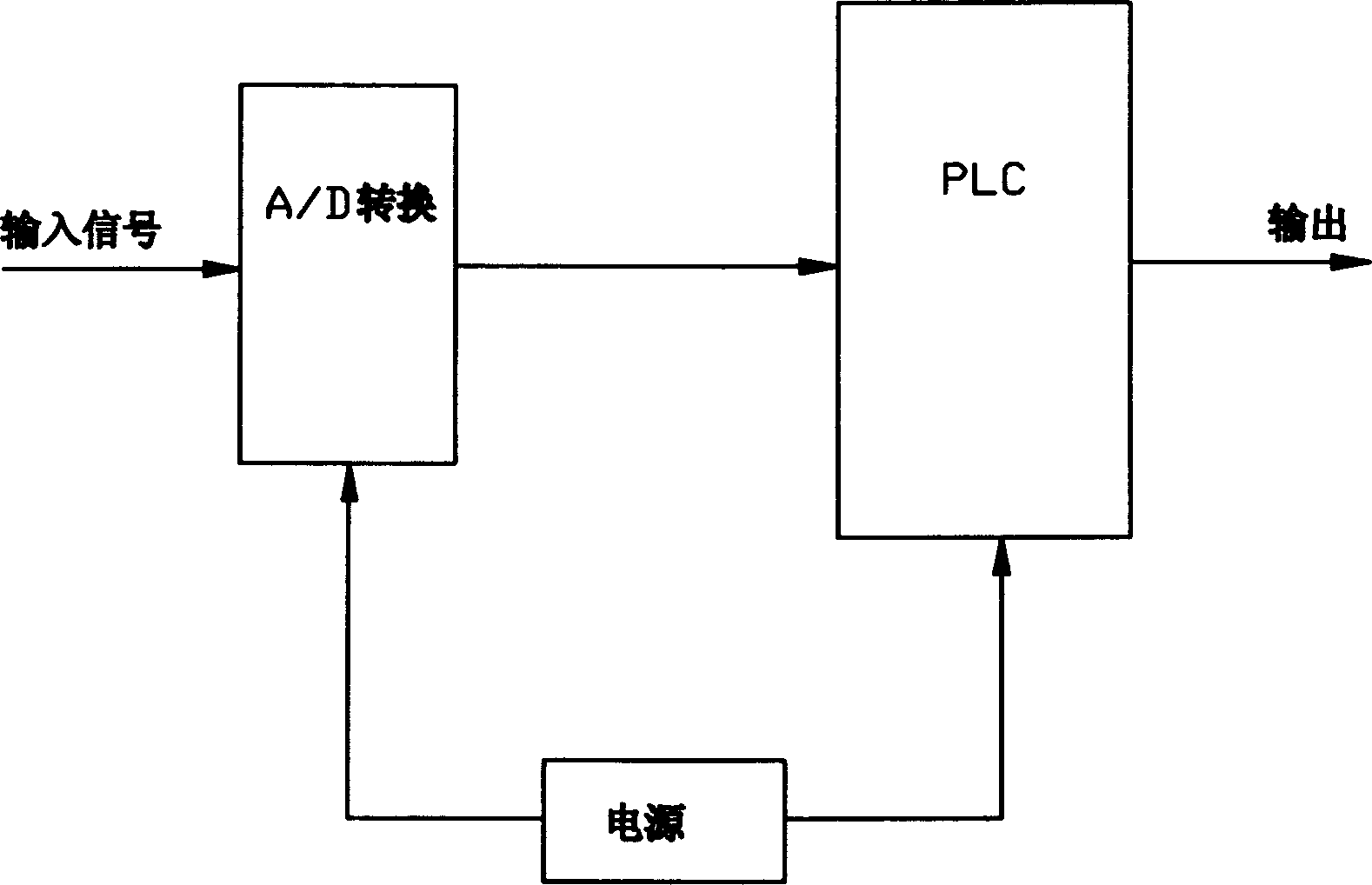

[0019] Step 1. Use optical fibers to collect optical signals generated due to failures inside the airtight equipment: pre-arrange optical fibers (groups) 2 inside the airtight power equipment 1, especially the ones with good light transmission and insulation performance in the near-infrared to near-ultraviolet wavelength region The outer sheath of the quartz fiber is made of polytetrafluoroethylene material or epoxy resin material with a temperature resistance of more than 100°C, long-term stability in the insulating medium (such as transformer oil) and good insulation performance, so that the input of the fiber The end faces the monitored part, and the fiber group composed of multiple optical fibers can be arranged according to the needs to monitor various fault-prone parts inside the equipment. In order to improve the optical signal receiving effect of the optical fiber, a lens can be added in front of the input end, such as connecting a hemispherical lens to the optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com