Wear resistant casting ball automatic separator

A technology for automatic separation and wear-resistant cast balls, applied in the field of post-processing devices for wear-resistant cast balls, can solve the problems that restrict the large-scale, mechanized mass production of wear-resistant cast balls, harsh working environment, and high labor intensity. Achieve the effect of improving work efficiency, reducing production costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

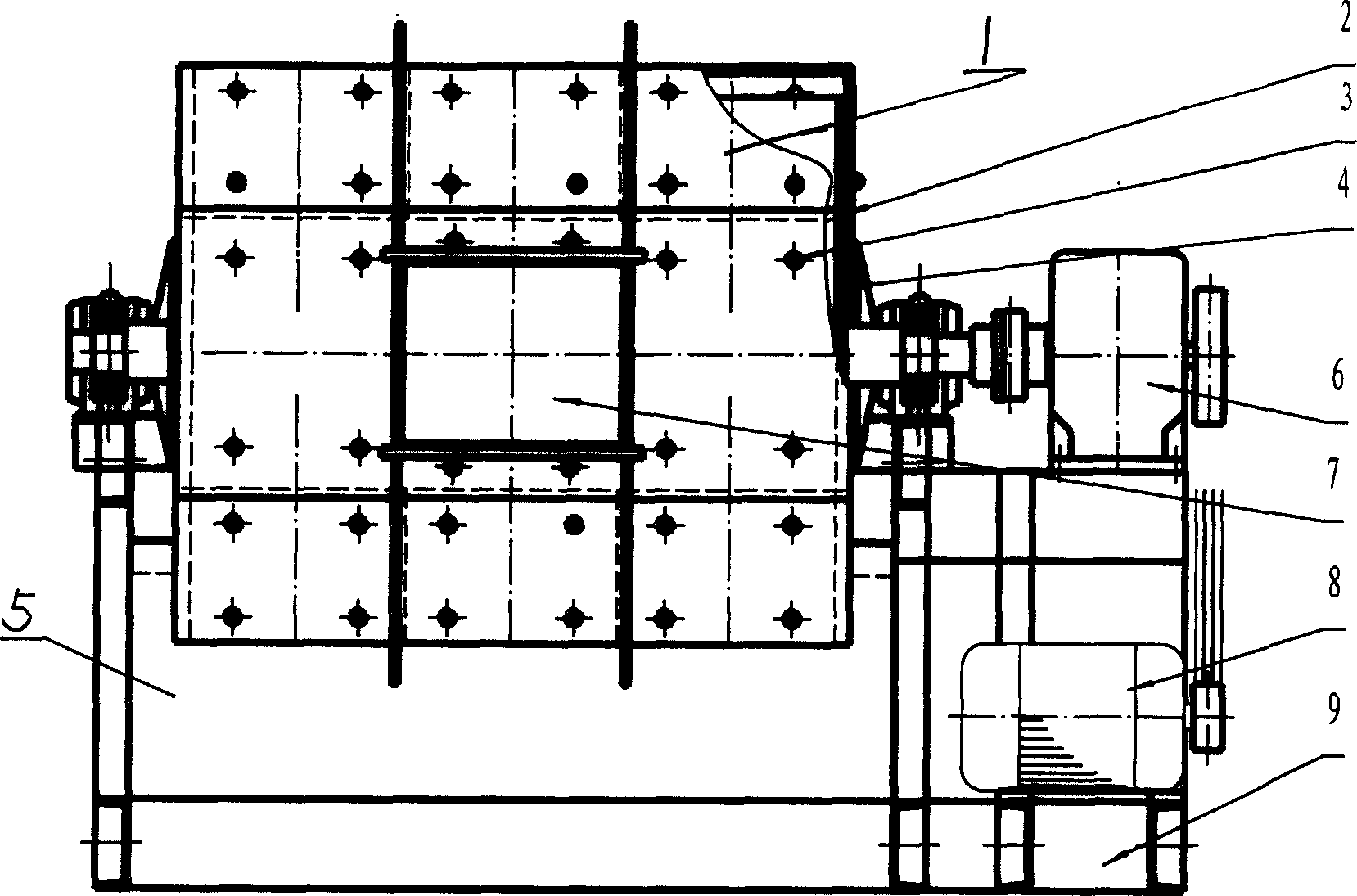

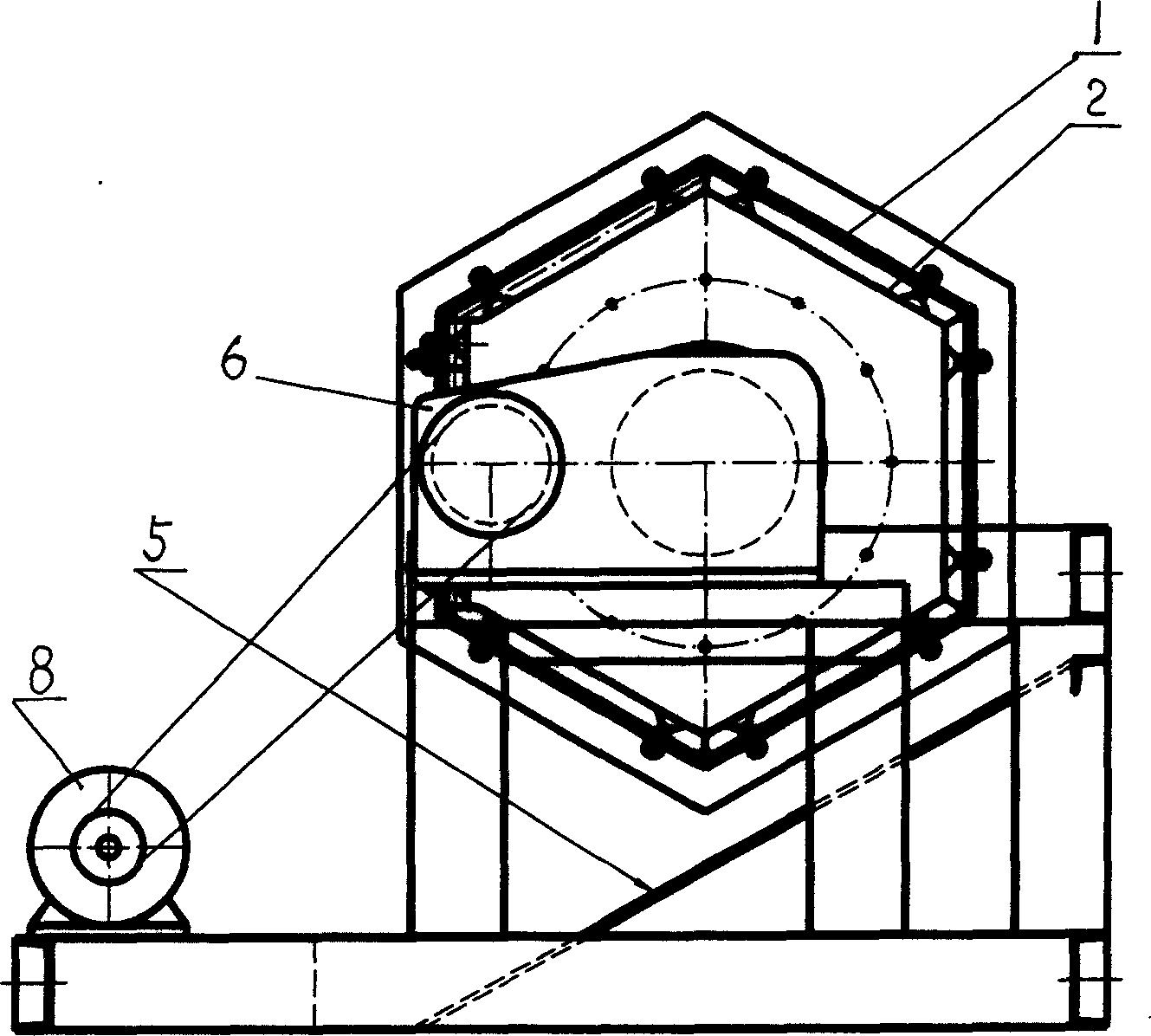

[0017] This embodiment includes a frame 9, a drum 1 and a transmission mechanism. The drum 1 is a hexagonal cylinder, and the drum 1 is fixedly installed on the frame 9 through the transmission shaft and the shaft seat at both ends. The material door 7 is installed on the drum 1, and the wear-resistant liner 2 is fixedly installed on the inner wall of the drum 1 in turn. , and fixed on the inner wall of drum 1 with evenly distributed fastening bolts 3, drive shafts are respectively installed at both axial ends of drum 1; The input shaft of the device 6 is connected with the motor 8 through a transmission belt, the output shaft of the reducer 6 is connected with the transmission shaft of the drum 1, and a discharge inclined guide plate 5 is installed below the drum 1 .

[0018] When in use, the one-piece casting ball with a pouring riser is added to the drum 1 from the material gate 7, and the material gate 7 is closed. Driven by the motor 8 and the reducer 6, the drum 1 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com