A permanent magnetic synchronous motor

A technology for permanent magnet synchronous motors and magnetic poles, which is applied in the direction of synchronous machine parts, manufacturing stator/rotor bodies, etc., and can solve problems such as small starting torque and difficult starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

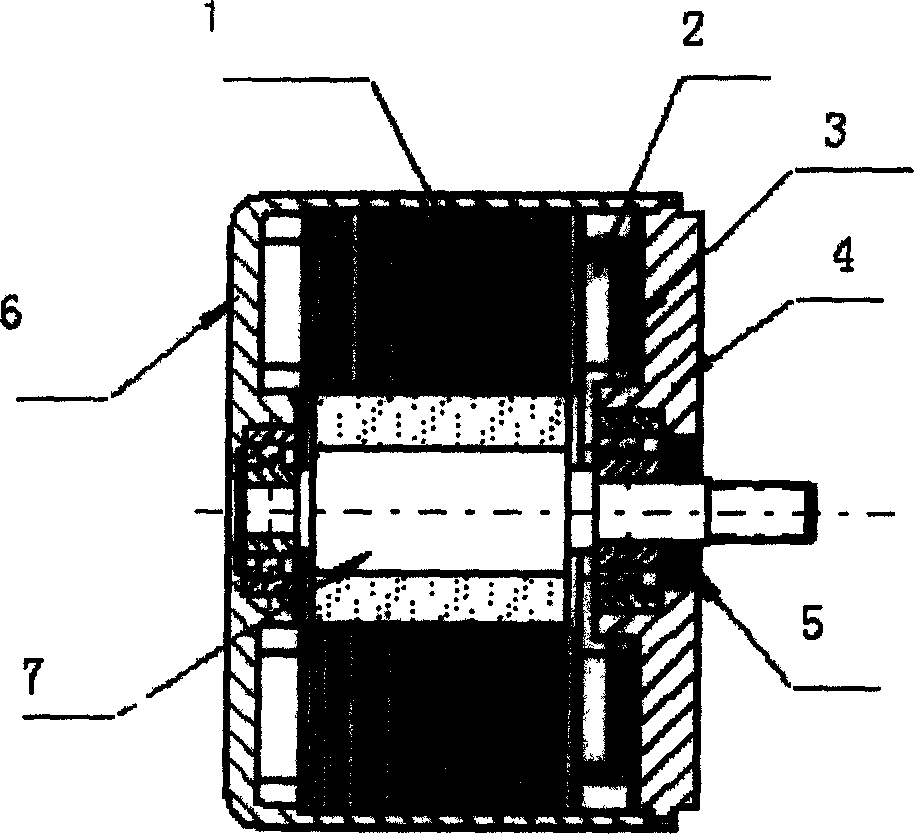

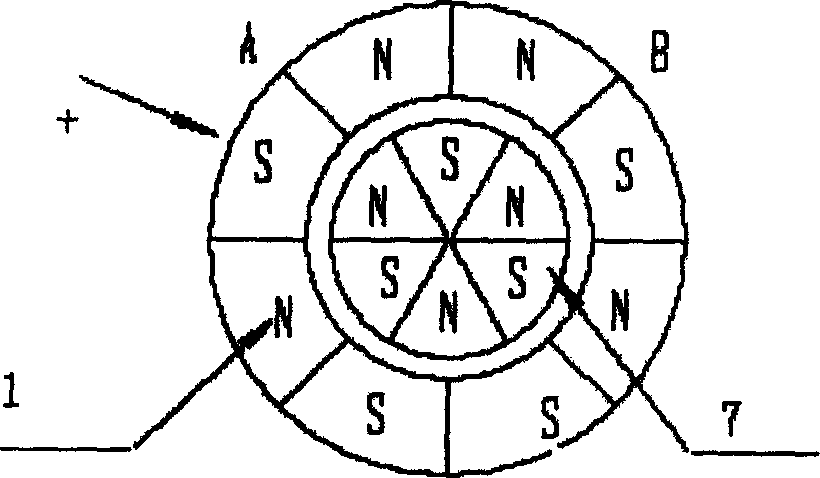

[0012] refer to figure 1 , a permanent magnet synchronous motor, including a stator and a rotor 7, the stator includes a core 1, a stator coil 3, a casing 6 and an end cover 4, and the rotor 7 is composed of permanent magnets. The number of poles of the stator and the rotor are 8 and 6 respectively; the rotor poles are alternately distributed; two pairs of stator poles are alternately distributed, and are mirror-symmetrically arranged with the other two pairs of alternately distributed stator poles. The stator is provided with 8 coil windings, which are wound in 8 slots of the stator iron core through 8 coil bobbins, the stator iron core is embedded in the casing, and a circuit board 3 is installed at the end of the stator. Each joint of the coil 2 is welded on the circuit board 3, and is connected to an external circuit through the circuit board 3. A piece of magnetic steel sticks on the outer circle of the rotor shaft, and two bearings are respectively placed in the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com