Reducing color segregation in HID lamps

A discharge lamp and signal technology, applied in the use of gas discharge lamps, output power conversion devices, high-efficiency power electronic conversion, etc., can solve problems such as high color temperature and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

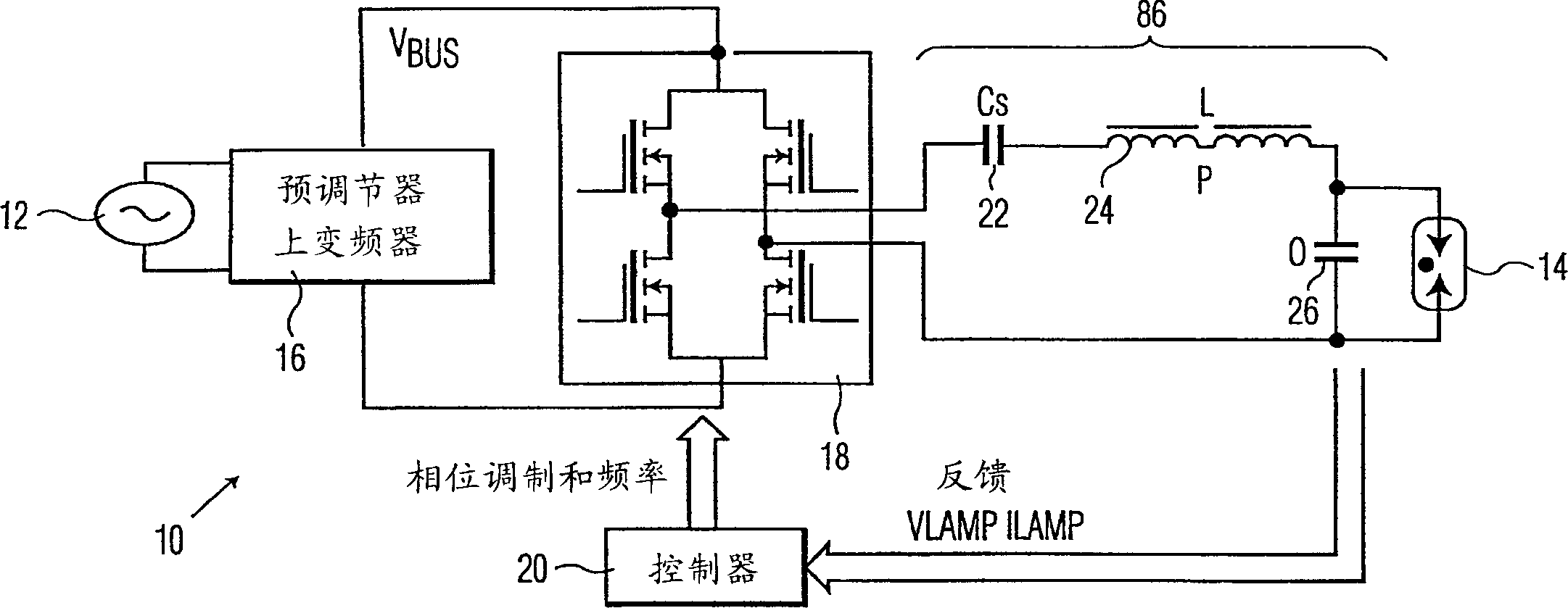

[0034] figure 1 An electronic ballast circuit 10 according to one embodiment of the present invention is shown. The main power supply 12 provides an AC current signal to the high and low voltage power bus, V BUS is ultimately used to drive the lamp 14 . The ballast circuit 10 includes a pre-regulator and upconverter 16 configured to receive a rectified signal of the mains power signal and shape the ballast supply current (which may also be referred to as the mains current) for power factor correction. Advantageously, the pre-regulator and up-converter 16 comprises a boost converter (not shown), the operation of which is well known in the art.

[0035] The ballast bridge unit 18 is configured to receive the signals provided by the pre-regulator and up-converter 16 . The ballast bridge unit 18 has the function of a commutator, that is, the polarity of the voltage signal supplied to the lamp 14 is changed through the filter circuit 86 . The ballast bridge unit 18 includes fou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap