Fiber glass raster stress temp sensor

A technology of temperature sensor and fiber grating, applied in the field of fiber grating sensor, fiber grating stress temperature sensor, can solve the problems of low sensitivity and measurement accuracy, difficult to distinguish compressive stress and tensile stress, etc., achieve high sensitivity, good market prospect, Stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

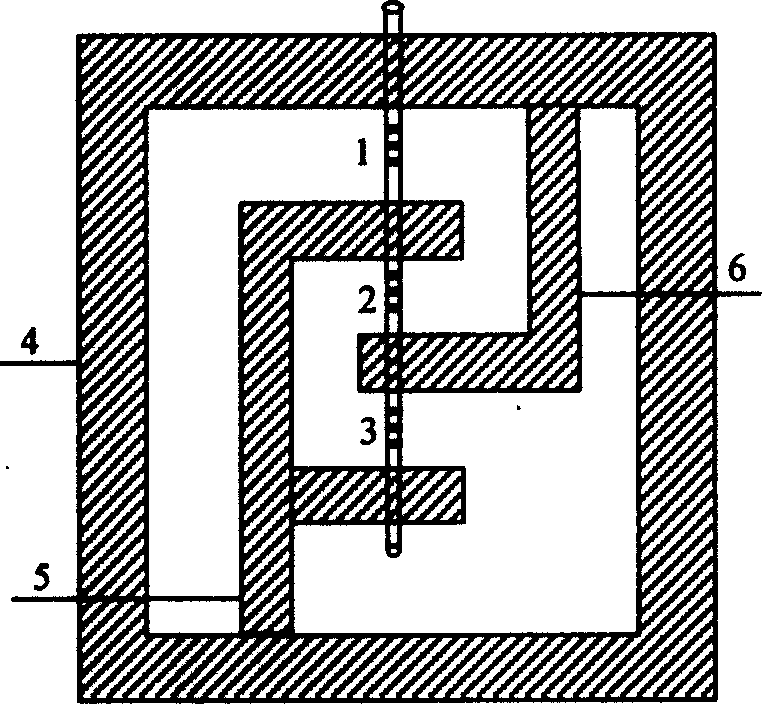

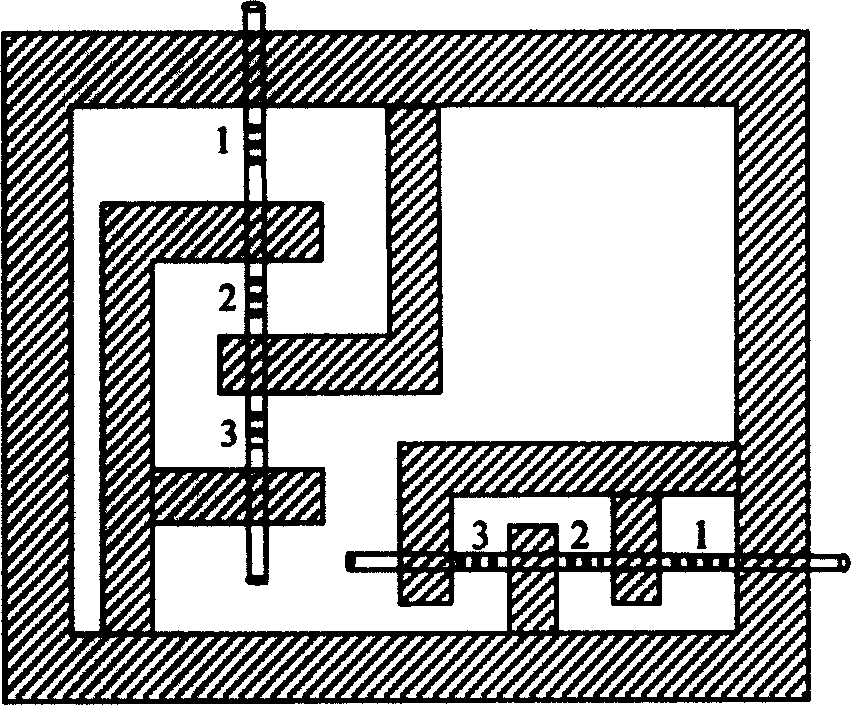

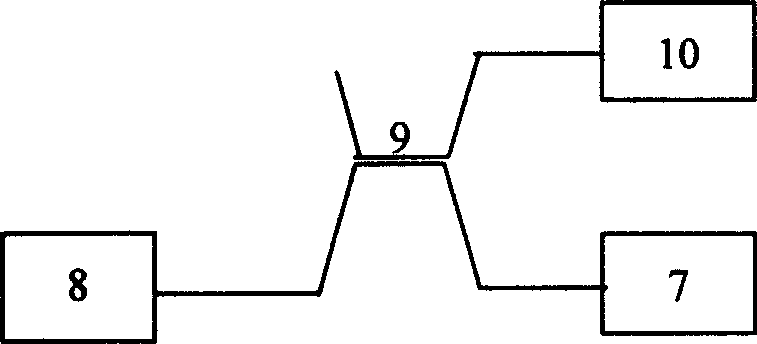

[0041] The structure of the fiber grating stress temperature sensor of the present invention is as follows figure 1 As shown, it includes sensing probe optical fiber, insulating fixed frame and two insulating moving frames, and an F-shaped moving frame 5 and an L-shaped moving frame 6 are respectively fixed on the upper and lower frames of the fixed frame 4, and the two moving frames are mutually Arranged in a staggered manner, the sensing probe fiber is fixed on the fixed frame 4, and passes through the upper end of the fixed frame 4 and the interlaced parts of the two moving frames. Opened fiber grating, the first fiber grating 1 is mainly used to measure the stress type, whether it is compressive stress or tensile stress, the reflection spectrum peak wavelength of the second fiber grating 2 and the third fiber grating 3 are the same, mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com