Negative pressure fully automatic upper/lower sheet device of laser plotter

A fully automatic, negative pressure technology, applied in the direction of optomechanical equipment, optics, instruments, etc., can solve the problems of manual positioning, low yield rate, and low work efficiency of photoplotters, so as to eliminate influence, improve yield rate and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

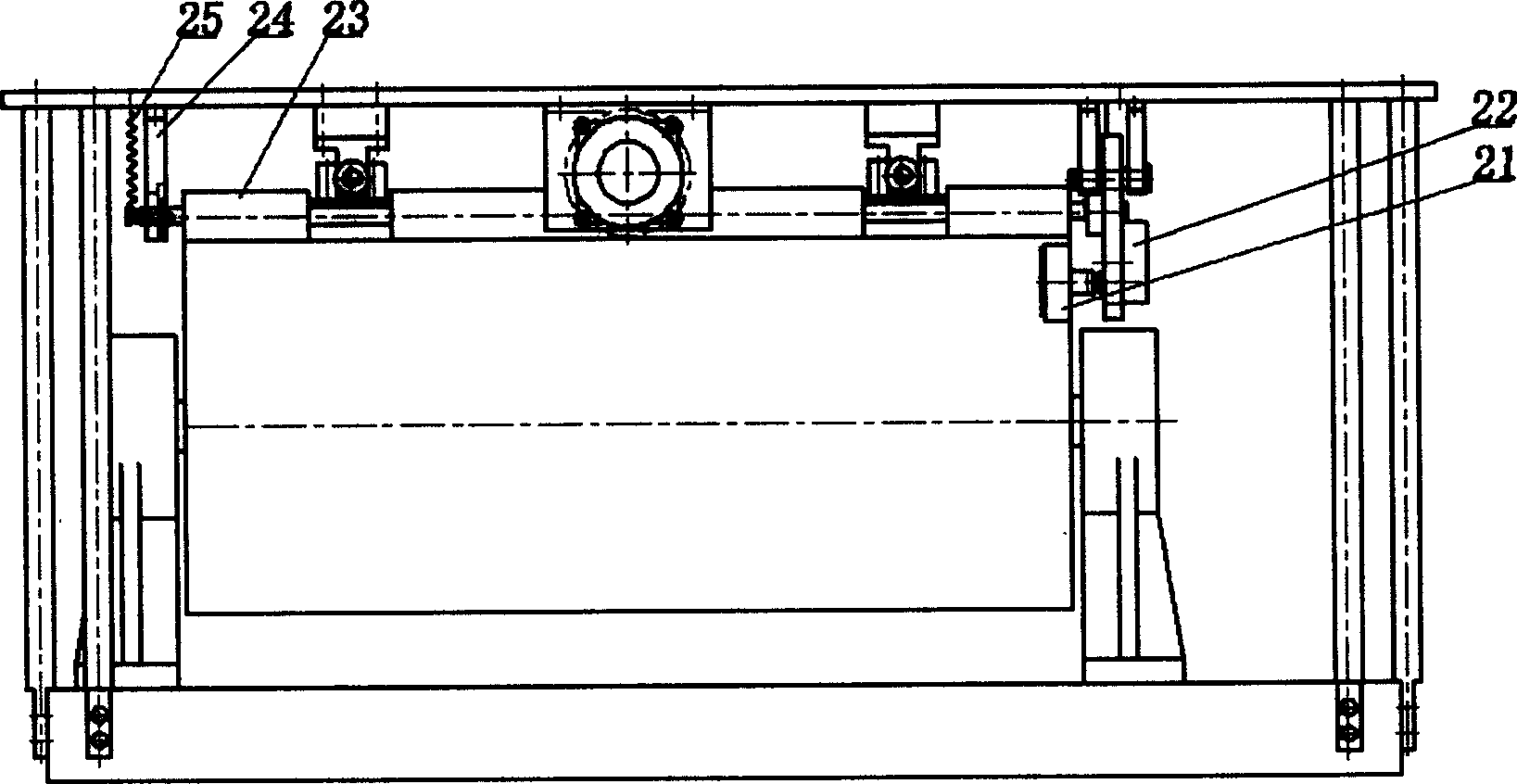

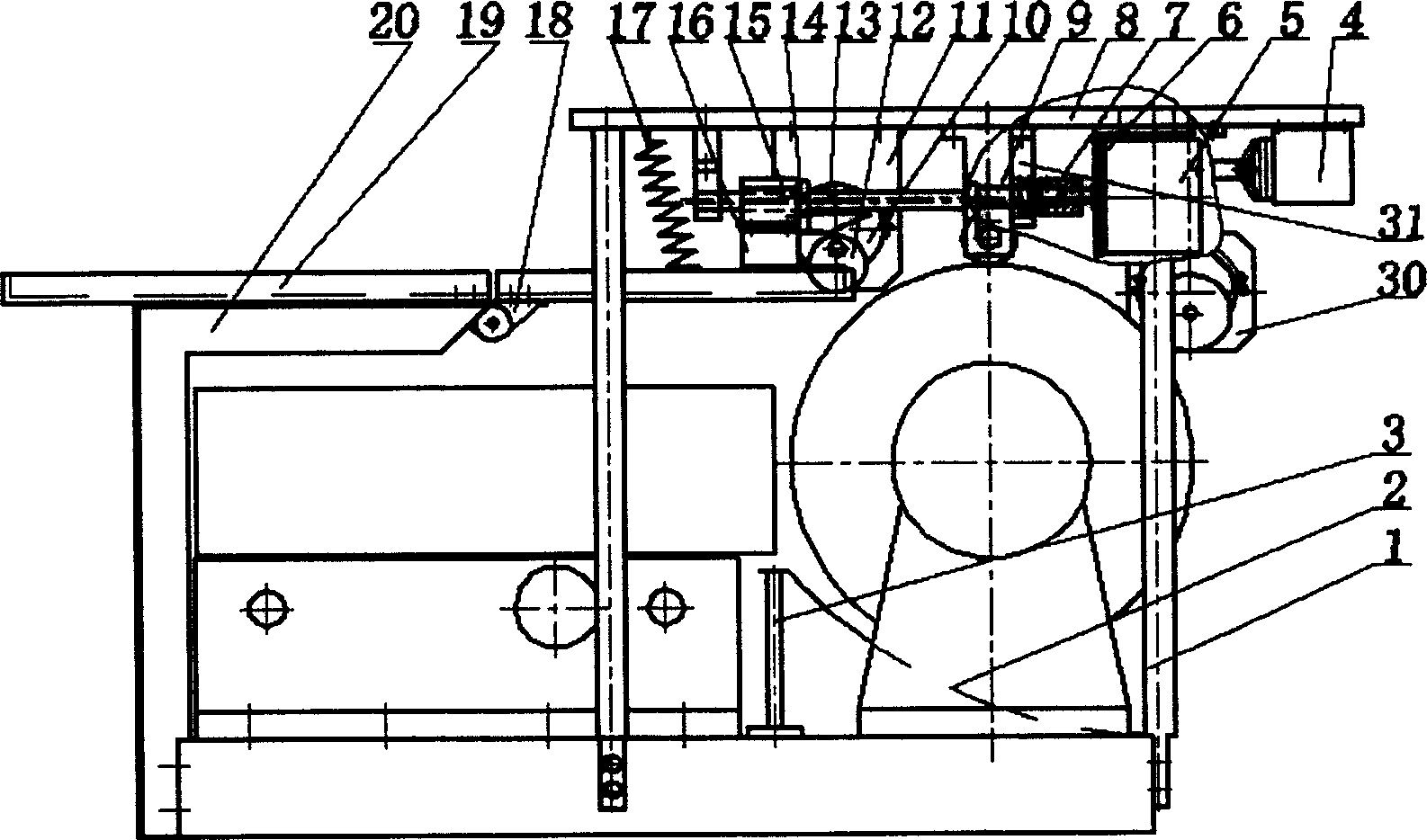

[0019] Laser photoplotter negative pressure automatic loading and unloading device, such as Figure 1a and Figure 1b As shown, the device is fixed on the platform of the laser photoplotter through four uprights 1 and two angle iron frames 20, and a small platform 8 is fixed on the top of the uprights. The automatic loading and unloading device includes:

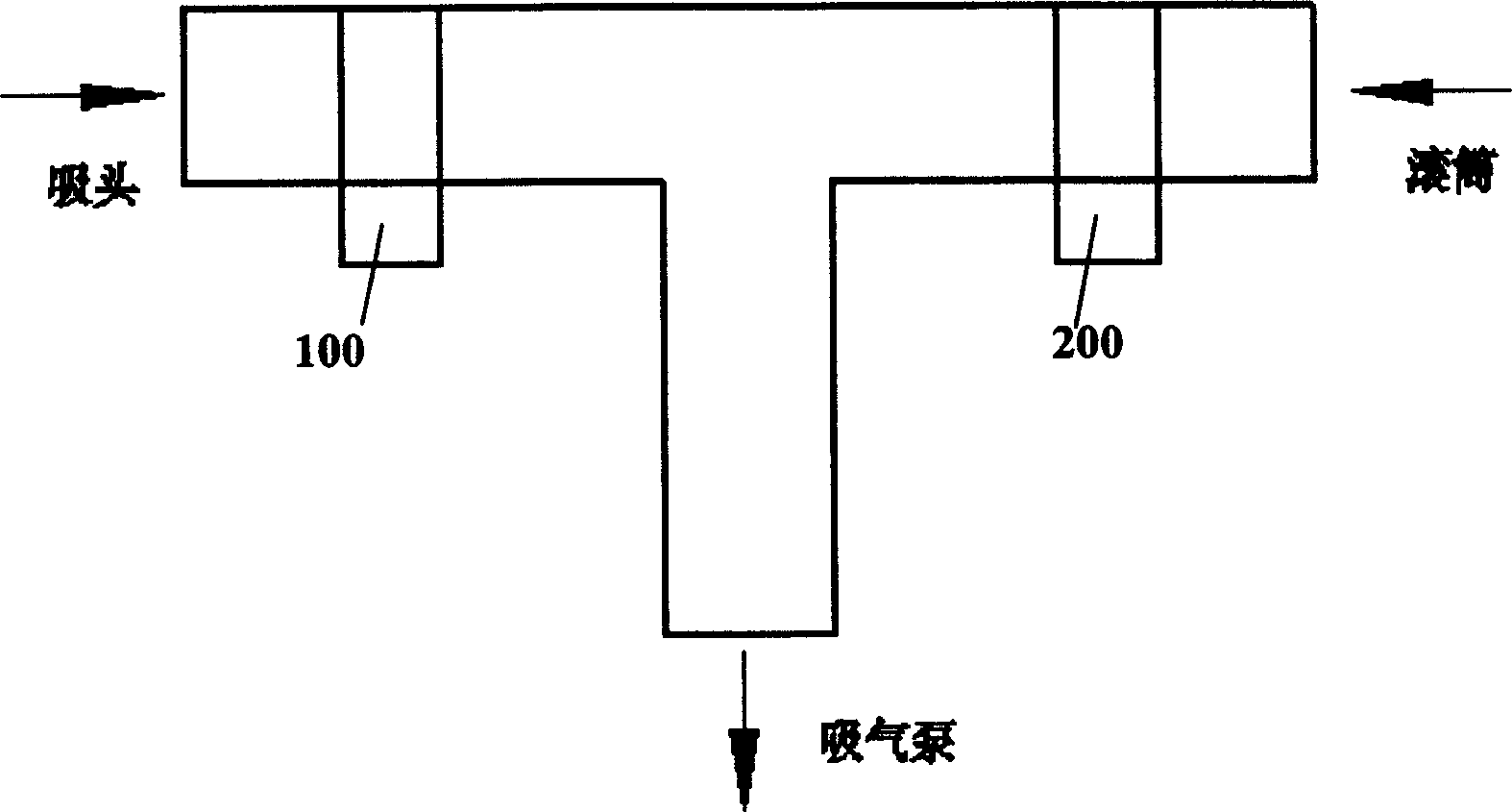

[0020] Airflow control part, this part includes the airway that is arranged on the laser photoplotter, suction pump, suction head 16 and two normally closed electromagnetic reversing valves, and the suction pump is arranged at one end of the airway joint, The suction head 16 and the cylinder of the laser photoplotter are respectively arranged at the other two ends of the airway joint, and the two electromagnetic reversing valves control the air flow to the suction head 16 and the cylinder respectively;

[0021] The film box part, which includes angle iron frame 20, film box 19, hinge 18, spring 17, motor bracket 11, eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com