Fiber collecting device for ring spinning frame

A spinning frame and fiber technology, which is applied in the field of fiber strand gathering and compacting device in the drafting system of ring spinning frame, which can solve problems such as accidental drafting of fiber strands, failure of compacting force provided by the gathering top roller, unreliable power transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

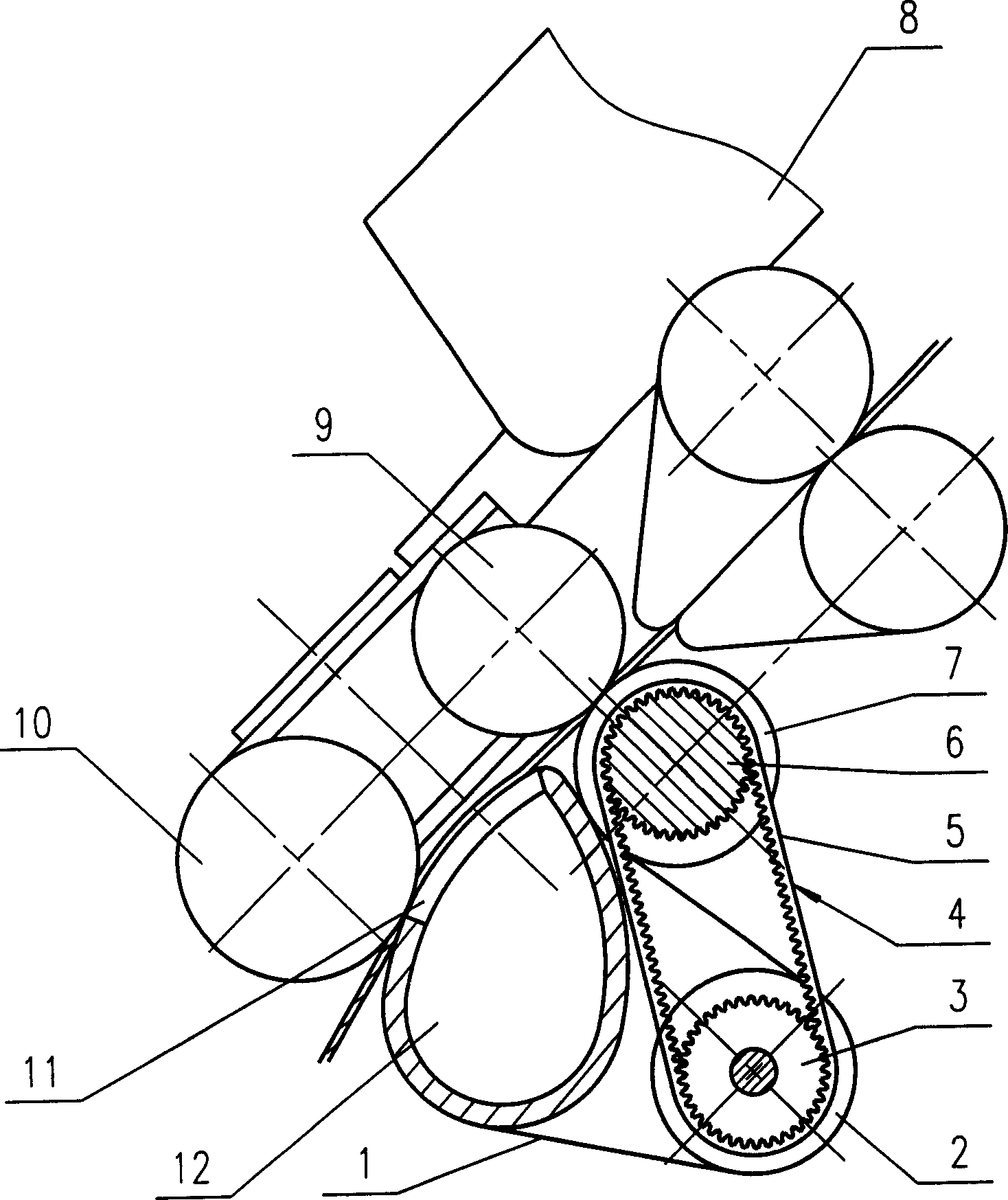

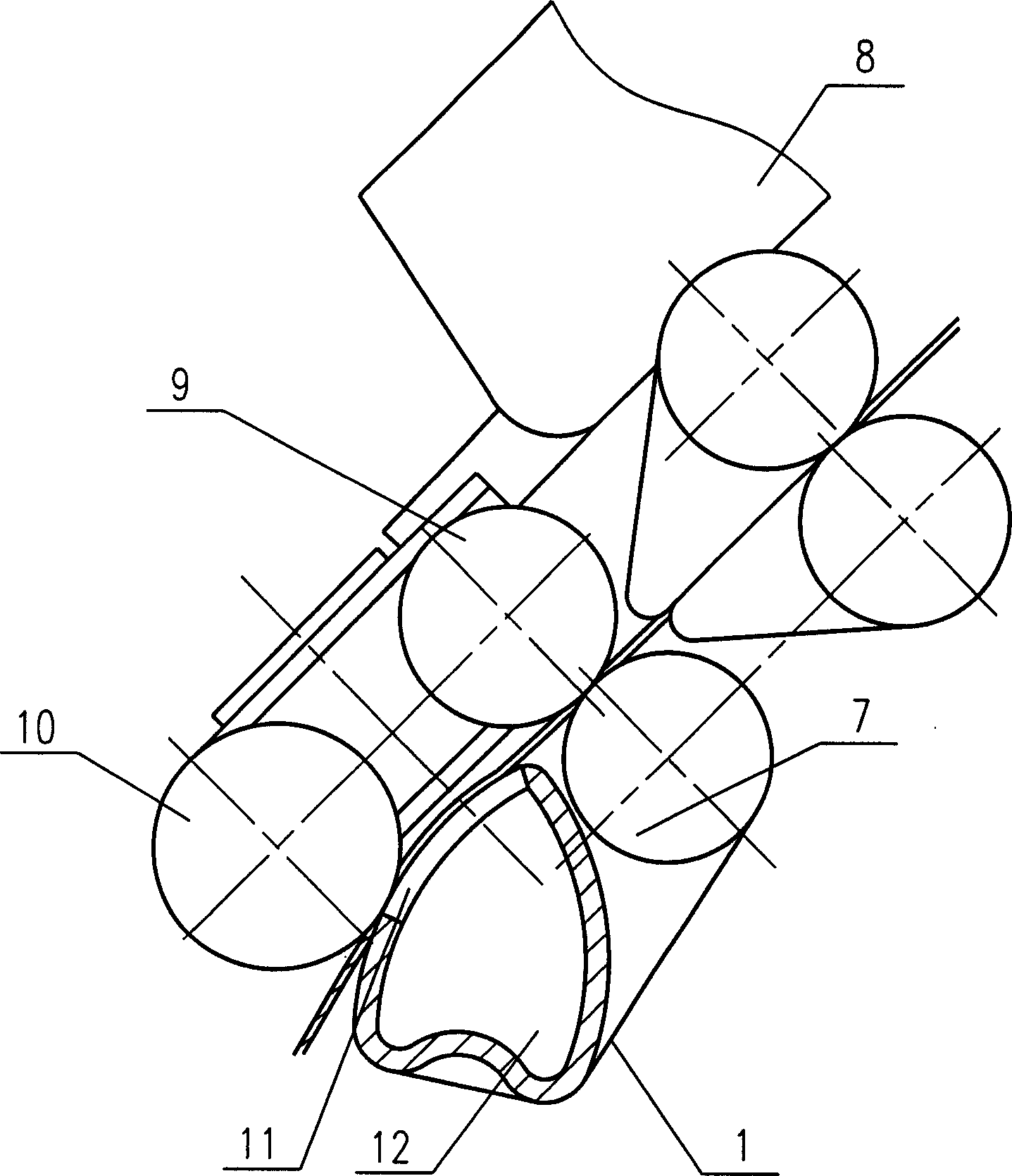

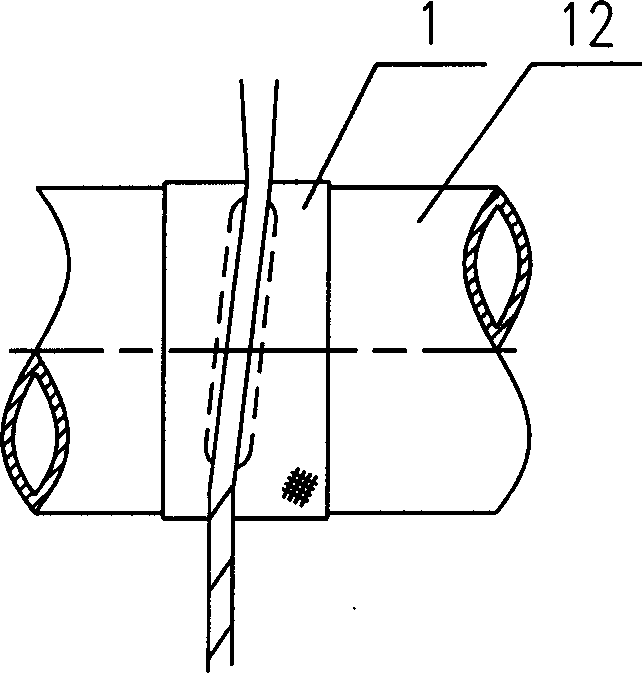

[0016] figure 1 The shown structure only shows a schematic view of the end area of the fiber drafting and gathering device arranged on each spinning position of a ring spinning frame. In the figure, the front top roller 9 and the accumulation top roller 10 are rotatably supported on the same support frame, and the front top roller 9 is mounted on the front end of the cradle 8 under pressure; There is a suction pipe 12 below the air suction pipe 12, and there are several suction grooves 11 on the suction pipe 12. The suction pipe 12 is connected with a negative pressure air source, and the conveyor belt 1 is set on the suction pipe 12 and the middle driving roller 2. The position of each suction slot 11 on the suction pipe 12 and the conveyor belt 1 on it corresponds to the fiber bundle of each spindle position; the front roller 7 and the intermediate drive roller 2 are transmitted through the belt drive Power; the front side of the front roller 7 is in contact with the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com